Through the understanding of the existing casting process of turbocharger, combined with the current situation of the casting process and the existing research results, the defects of the existing turbocharger shell casting process are summarized and sorted out, and the existing defects of the turbocharger shell casting process are found:

First, the casting blank has a large edge overflow on the parting surface of the die. The edge overflow problem not only damages the casting quality of the shell, but also prolongs the machining time. At the same time, it directly leads to the increase of the manufacturing cost of the shell, and leads to excessive loss of raw materials in the manufacturing process, which inevitably affects the production efficiency of the shell;

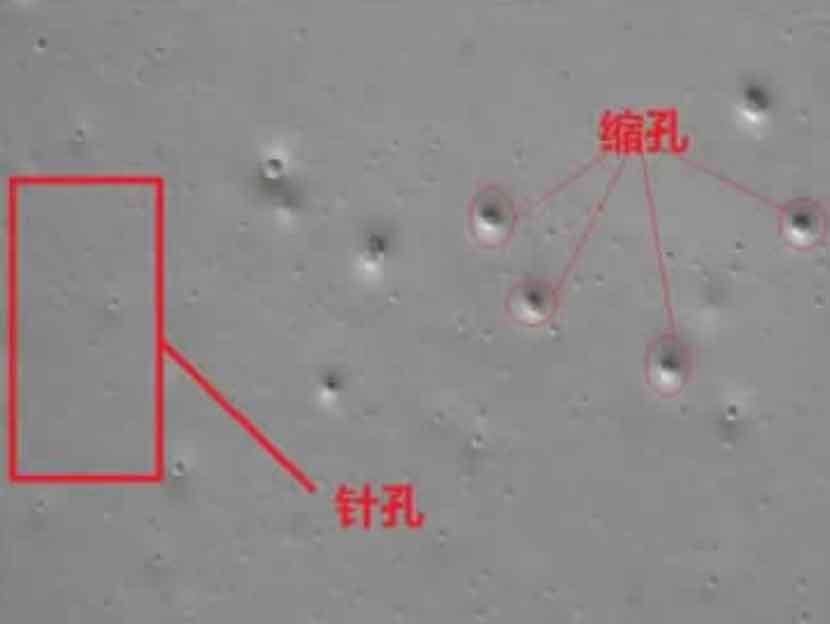

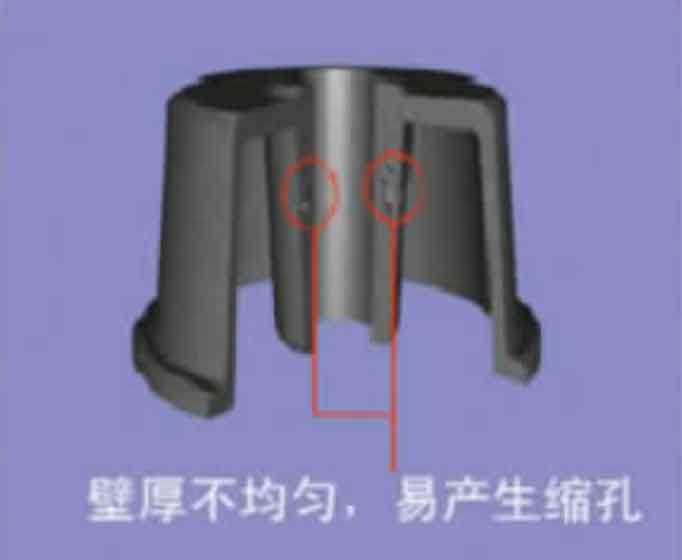

Second, there are porosity and shrinkage casting defects in some parts of the casting, which affect the quality and accuracy of the pressure shell, resulting in the unqualified quality problems of the turbocharger, and then affect the use of the turbocharger.

Figures 1, 2 and 3 are schematic diagrams of casting process defects.

Based on the relevant research on the casting process of turbocharger shell and the analysis and understanding of the concept and structure of turbocharger, the key process of turbocharger shell casting process and the analysis and Research on the current situation of existing casting process are summarized. Aiming at the defects of existing technology, the direction and measures to improve turbocharger casting process are put forward, To better ensure the casting quality of turbochargers, make them widely used, promote the further development of turbochargers, promote the process of energy conservation and emission reduction in the automotive industry, and improve fuel economy; Better respond to the national call for energy conservation and emission reduction, reduce vehicle exhaust emissions and continuously improve people’s quality of life.