Taking a certain type of wheel as the research object, the A356 cast-rotating aluminum alloy wheel blank is mainly manufactured by three processes: low-pressure casting, hot spinning and heat treatment T6. First, the wheel blank (spoke+thick rim) is obtained by low pressure casting process. The rim and inner rim with higher strength are required to undergo spinning processing. After spinning, the blank is finally subject to T6 heat treatment for strengthening.

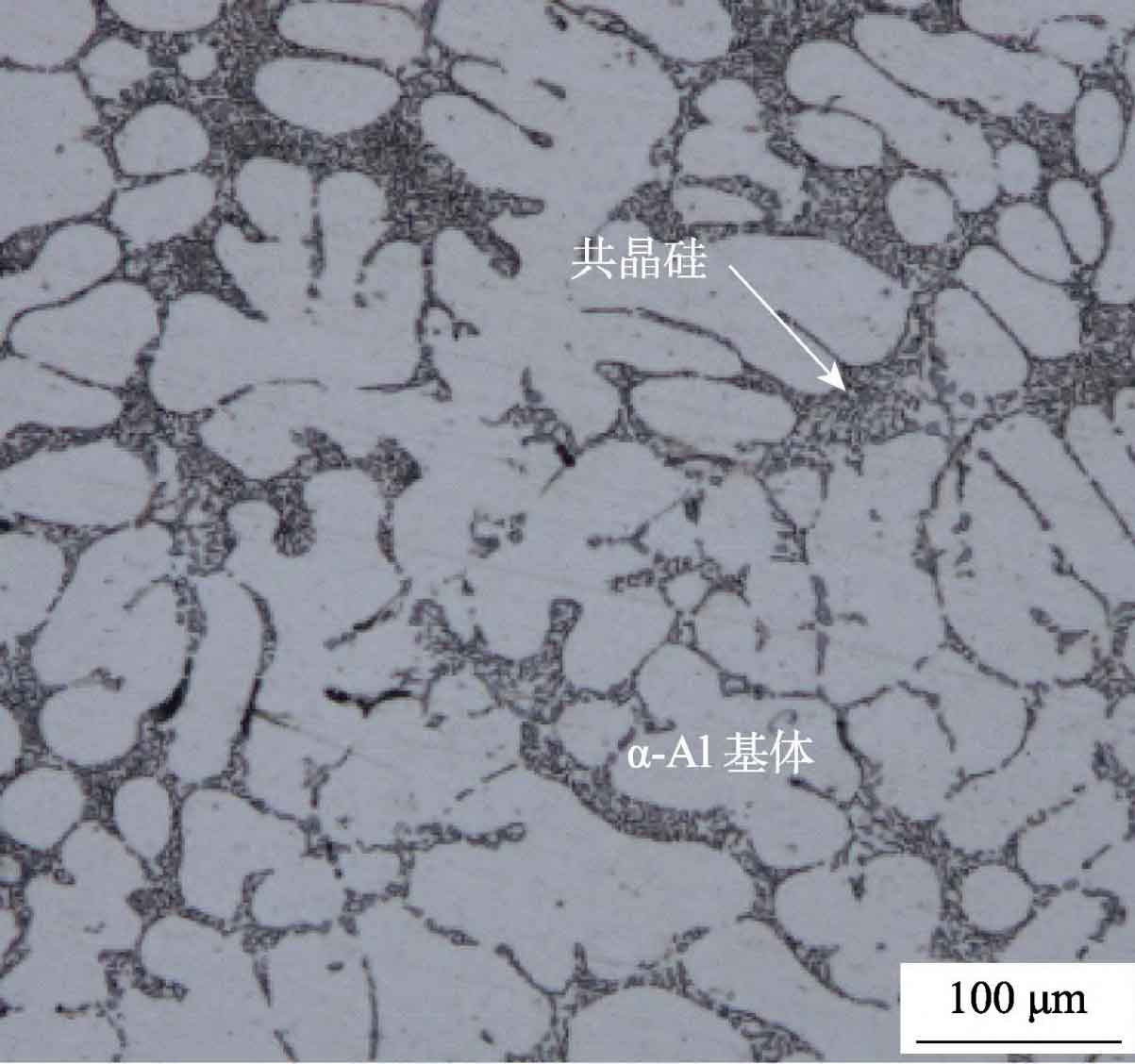

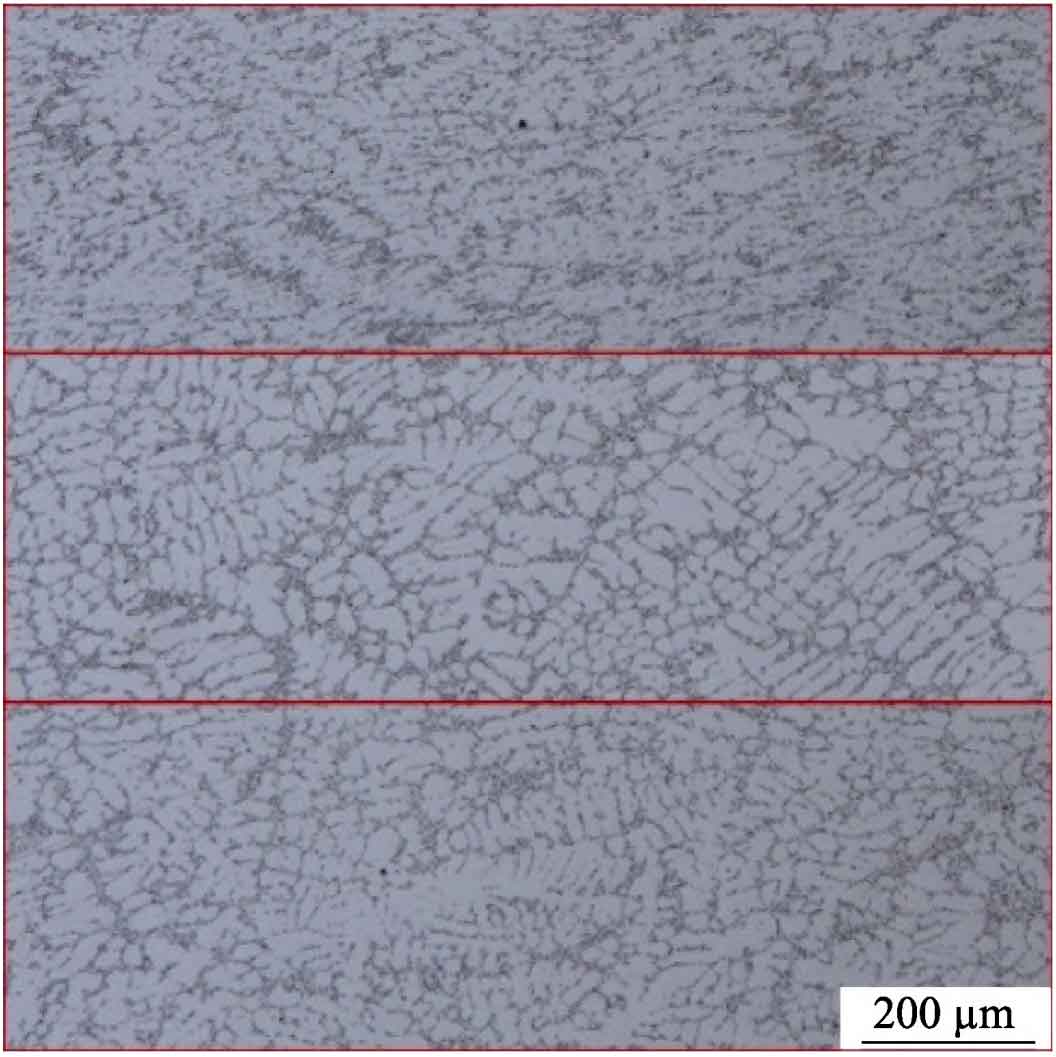

The as-cast structure of A356 after low-pressure casting T6 is shown in Figure 1. Due to the existence of coarse eutectic silicon particles and the uneven distribution of precipitates, the mechanical properties of A356 aluminum alloy are low.

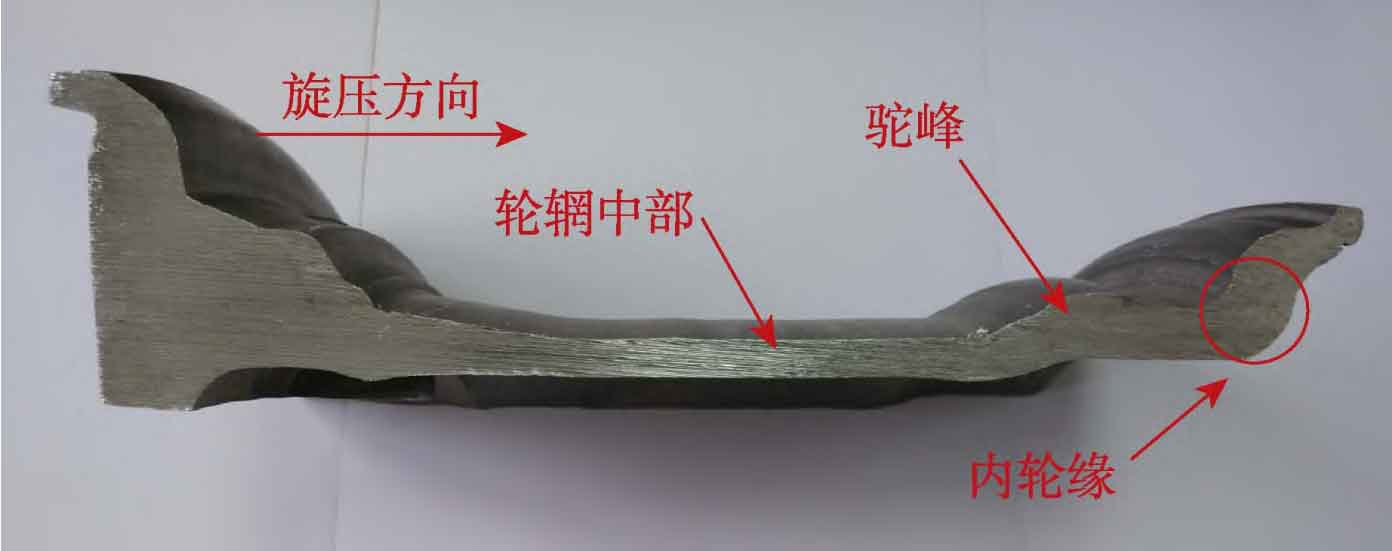

The strength of A356 is largely determined by the grain structure, mainly including grain size, processing flow line and texture components. Figure 2 shows the cut piece of the wheel cut longitudinally after hot spinning and T6 heat treatment, which is mainly composed of the middle rim, hump and inner rim.

Figure 3 shows the combination diagram of the microstructure of the inner wheel rim under the existing process. From top to bottom, the microstructure morphology of the near spinning wheel area, the middle area and the near core mold area are shown respectively.

It can be seen from Figure 3 that the grain is elongated and refined in the area near the spinning wheel, but the coarse original as-cast structure can still be seen in the middle area and the area near the core mold, which indicates that the spinning process produces a small amount of deformation in the middle area and the area near the core mold of the inner rim.

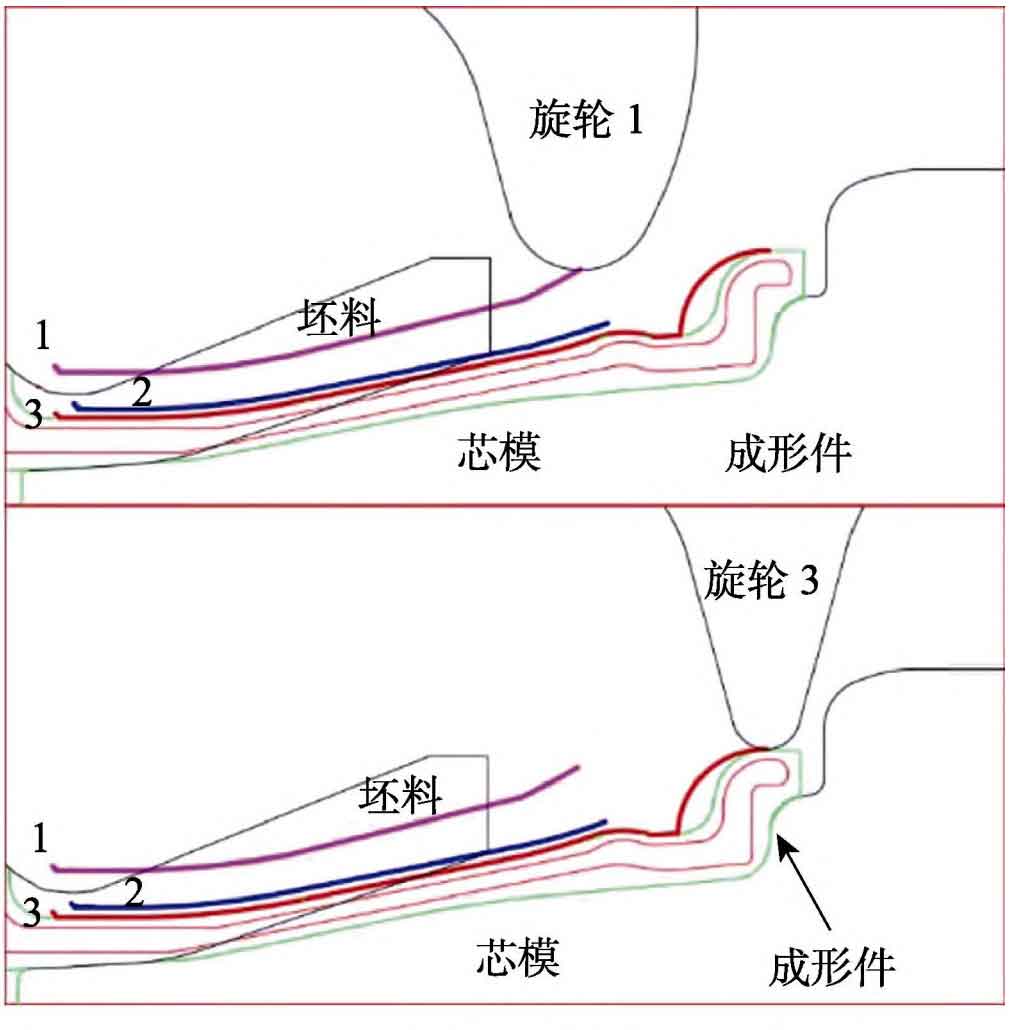

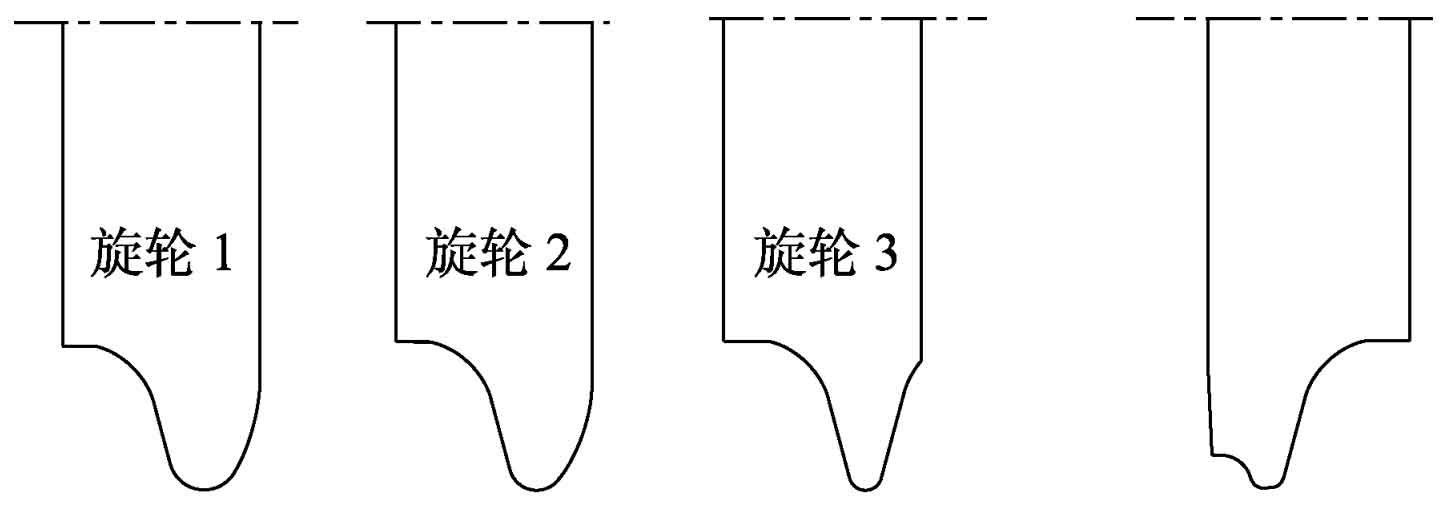

Figure 4a shows the spinning process of the existing (traditional) forming process. The spinning process of the A356 rim can be divided into two stages. In the first stage, roller 1 and roller 2 mainly form the middle of the rim and stay away from the core mold after completing the corresponding track. In the second stage, after the exit of roller 1 and roller 2, the hump at the end and the inner rim of the rim are formed by roller 3 separately until the final spinning part is obtained. During the whole spinning process, the feed speed of the three spinning wheels is 500 mm/min. The geometric structure of the three spinning wheels is shown in Fig. 5a.

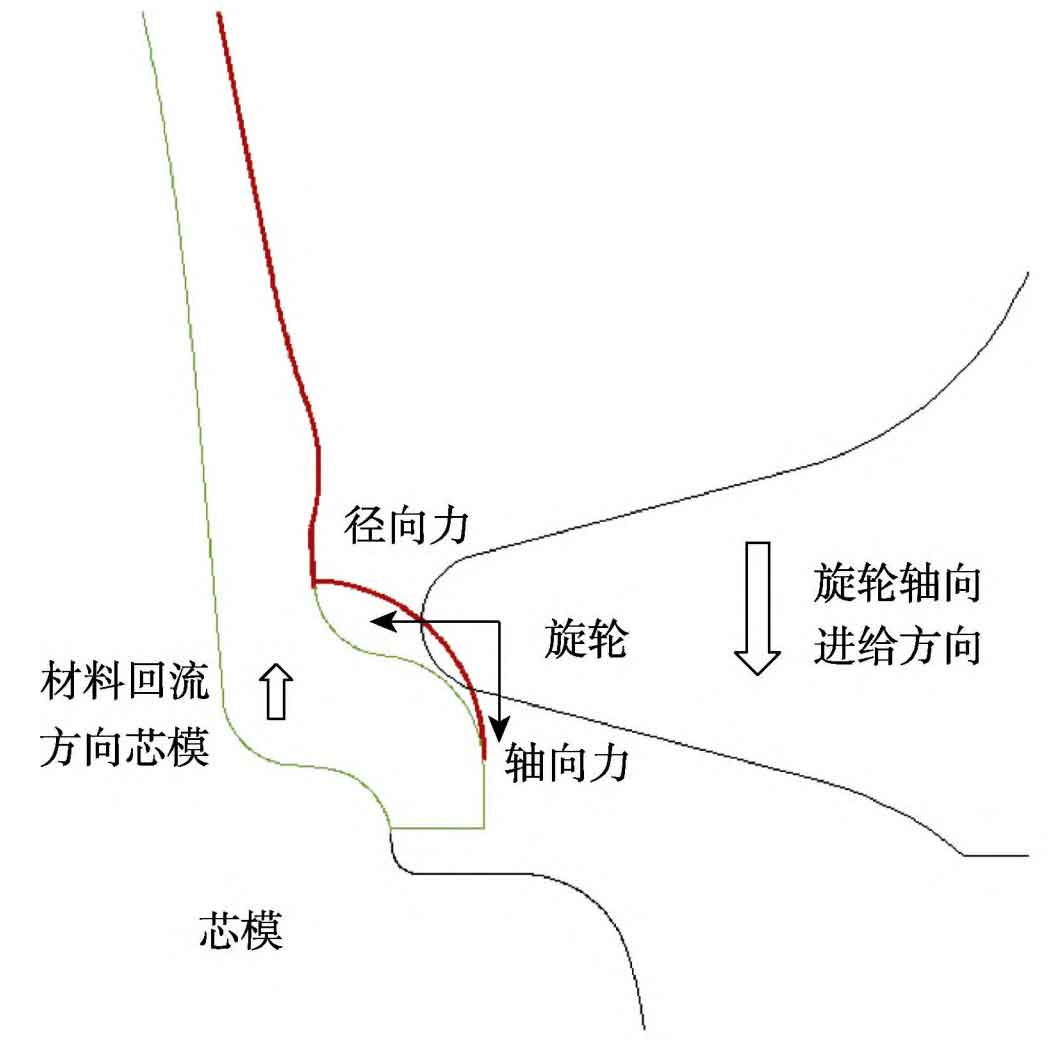

For the existing forming process, the insufficient performance of the inner rim is mainly caused by two reasons: insufficient material fluidity; The processing time is too short to completely deform the inner rim. When the wheel reaches the inner rim, the metal material flow is blocked, and the material tends to flow in the opposite direction, as shown in Figure 4b. This causes material backflow, which directly leads to insufficient deformation of the inner rim.

During the spinning process of wheel rim, the deformation of the material is mainly concentrated in the contact area with the wheel, that is, the external area. The deformation near the core mold is small, and the material of the inner rim part is particularly difficult to completely deform, resulting in its low mechanical performance. Therefore, how to improve the deformation and its uniformity in the thickness direction of the wheel blank, especially how to make the material of the wheel inner rim obtain sufficient deformation, is the key to improve the performance.