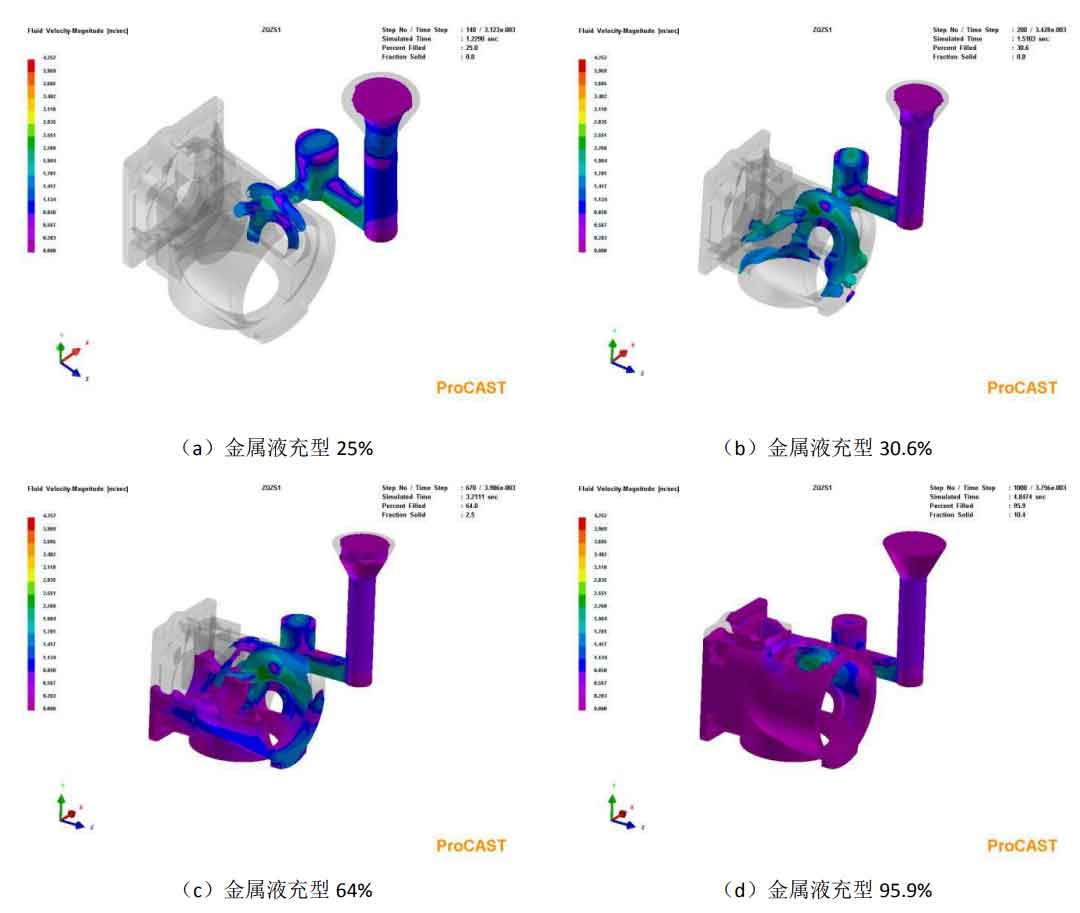

Figure (a) is a real-time screenshot when the molten metal just fills the sprue at the beginning of pouring and the molten metal enters the axle housing; The filling ratio of the cavity is 25% and the solidification fraction is 0.0%. Figure (b) reflects the beginning of the flow of the liquid metal in the axle housing when the cavity is filled. The filling ratio of the cavity is 30.6% and the solidification fraction is 0.0%; Figure (c) is a screenshot of the middle stage of liquid metal filling. The cavity filling ratio is 64% and the solidification fraction is 2.5%; Figure (d) is a screenshot of the later stage of filling the cavity with liquid metal. The filling ratio of the cavity is 95.9% and the solidification fraction is 10.4%. During pouring, under the action of gravity, the liquid metal first enters the mold cavity through the sprue, enters the transverse sprue, then the inner sprue, and finally enters the mold cavity of the axle housing to fill the whole process of the axle housing.

It can be seen from the velocity field in the figure that during the whole filling process of the mold cavity, the flow of the molten metal in the inner sprue is relatively stable, and the flow rate ratio of the molten metal is not much different, which is not easy to cause sand flushing and damage to the molding sand. In figure (b), a little molten metal is dispersed, the molten metal always fills the mold cavity, and the riser of the main transverse sprue plays a role in blocking the sand, So as to reduce the possibility of casting defects such as sand holes in the axle housing. It can be seen from figures (b) and (c) that the flow of liquid metal is stable and relatively uniform in the whole filling process, so it is judged that the scheme is better.