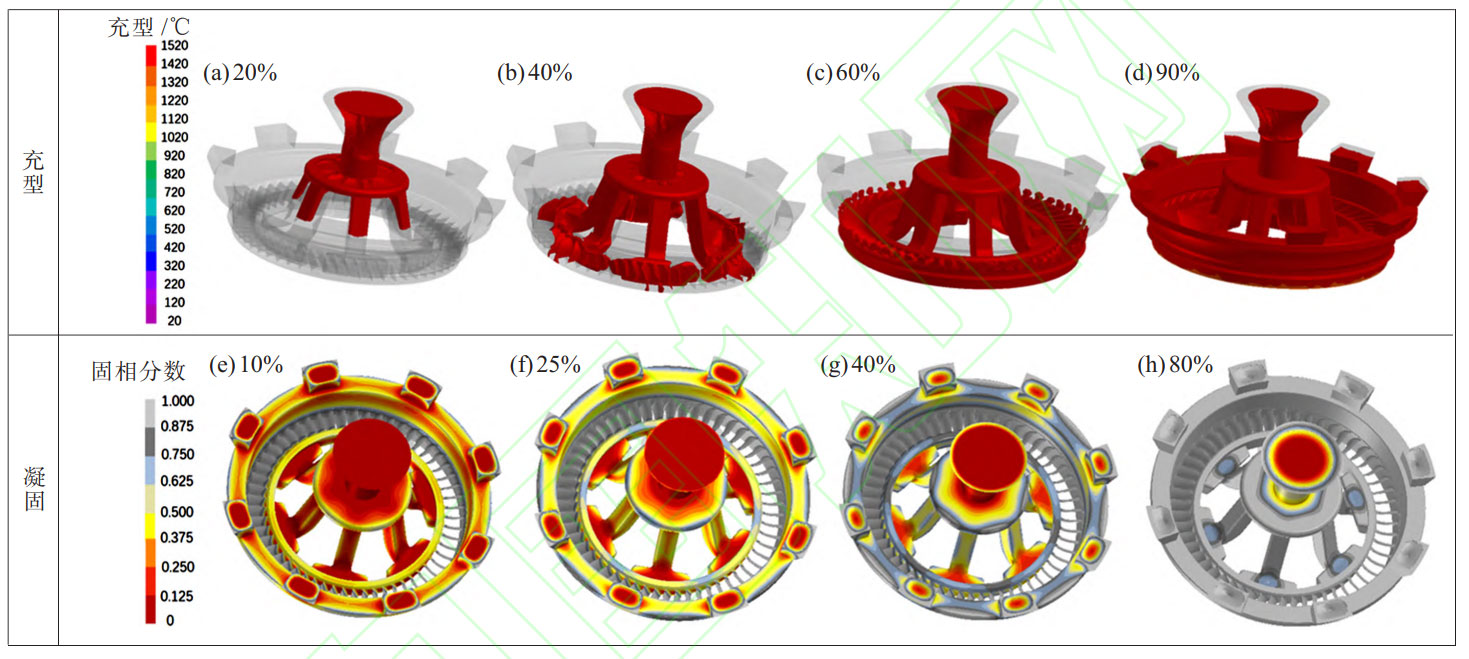

Figures 1 and 2 show the simulation results of the optimized filling solidification process of the turbine guide and the casting defects of the turbine guide. From Figure 1, it can be seen that when the mold is filled with 20%, the metal liquid in the diversion plate flows smoothly and evenly along the runner to the bottom gate; When the mold is filled with 40%, the metal liquid flows smoothly to the inner ring, blade, and outer ring, without any turbulence phenomenon; When filling 60% of the mold, the inner ring and blades have been filled with metal liquid, and the outer ring also has a certain filling height. At this time, the metal liquid in various parts of the outer ring is filling the flange and riser area smoothly, without any turbulence or gas holding phenomenon; When the mold is filled by 90%, the main body of the casting has completed the mold filling, and only a small part of the riser is not filled with liquid metal.

Further analysis of Figure 1 shows that when the solidification rate is 10%, the majority of the areas of the blade have completed solidification, and after optimization, the overall pouring system has shown a trend of sequential solidification; When the solidification rate is 25%, the connection between the outer ring and the blade has completed solidification, while the connection between the blade and the inner ring has not yet solidified. At this time, the non solidified area of the outer ring gradually solidifies towards the riser area from bottom to top, and the non solidified area of the inner ring gradually solidifies towards the bottom gate area; When the solidification rate is 40%, the flange area begins to gradually solidify, and there is already a partially fully solidified area in the connection area between the inner ring and the blade. At this time, there is still a lot of alloy liquid in the bottom gate and riser for feeding. After optimization, the overall pouring system has basically completed sequential solidification; When the solidification rate is 80%, the optimized overall pouring system only leaves some areas inside the bottom gate and the area inside the gate cup that have not yet fully solidified.

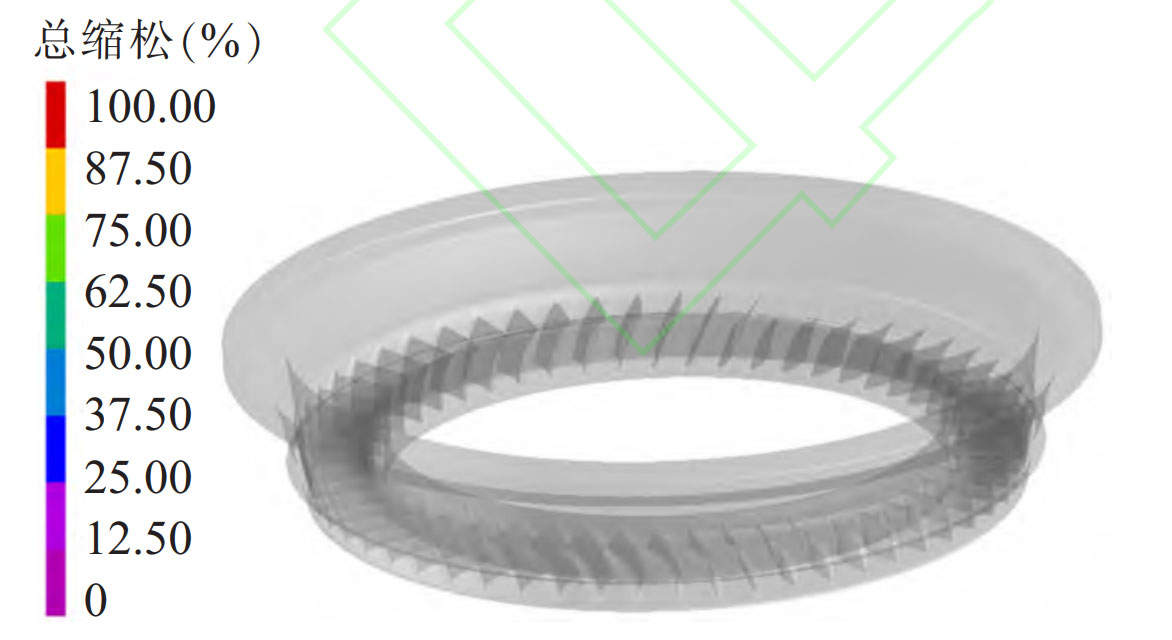

From Figure 2, it can be seen that no shrinkage porosity or porosity defects were found in the precision casting of the turbine guide. From this, it can be seen that the optimized precision casting process for the turbine guide has good filling stability and smoothness. The metal liquid solidifies sequentially according to temperature gradient changes, solving many shrinkage and porosity defects in the initial pouring system. At the same time, it also takes into account engineering technology costs, achieving the goal of cost reduction and efficiency increase. Therefore, the optimized precision casting process plan for the turbine guide is relatively reasonable.