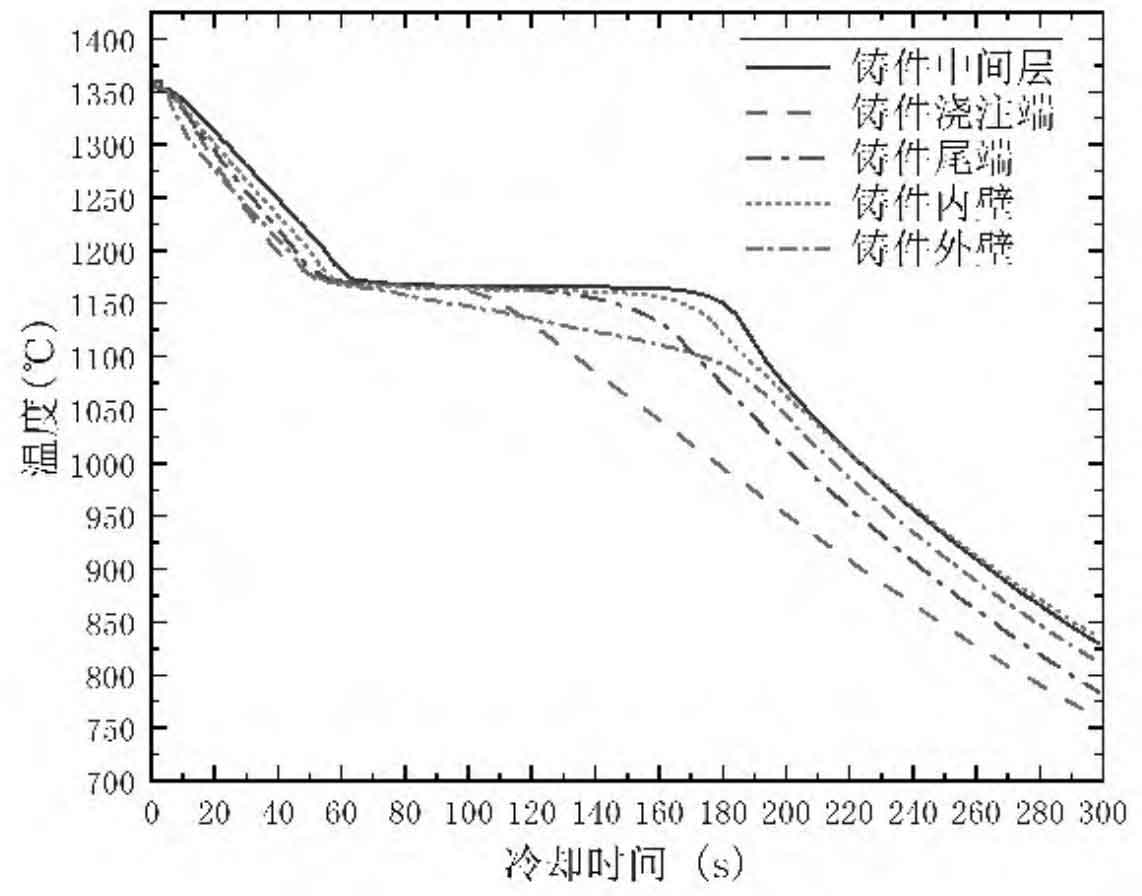

The simulation results of the initial centrifugal casting process temperature field are shown in Figure 1. It can be seen from the simulation results of the temperature field that during the solidification process of the centrifugal casting, the outer surface of the casting contacts the thermal insulation coating, and the thermal insulation coating contacts the mold. Because of the large temperature difference between the liquid metal and the mold at the initial stage of casting, the heat of the centrifugal casting is easily transferred to the mold with lower temperature, so the outer surface of the centrifugal casting is first cooled and solidified. The inner surface of the rotating centrifugal casting is in contact with the air, and the inner wall of the centrifugal casting is heat transferred through the air, causing the inner surface temperature of the centrifugal casting to be lower than the middle layer temperature of the centrifugal casting, so the inner surface of the centrifugal casting is not easy to produce defects.

The two ends of the centrifugal casting are in contact with the baffle plate and the mold, resulting in faster heat transfer at both ends of the centrifugal casting than at the middle section. In addition, due to the difference in the wall thickness of the centrifugal casting, there is more heat at the thick wall end. Therefore, in the process of air cooling, the temperature of the thick wall end mold of centrifugal casting rises rapidly, resulting in a higher temperature at the thick wall of centrifugal casting at the end of air cooling. Although the mold temperature tends to be uniform in the process of water cooling, it is difficult to make centrifugal casting cool evenly from the outside to the inside due to the existence of hot spots at the wall thickness of centrifugal casting itself.

The temperature distribution of the initial centrifugal casting process temperature field at t=150s is shown in Figure 2. The temperature of the inner layer of the casting is 1160 ℃, the temperature of the outer layer of the centrifugal casting is 1120 ℃, and the temperature of the intermediate layer of the centrifugal casting is 1180 ℃. The temperature at both ends of the centrifugal casting is low. This is because the temperature field of the centrifugal casting is distributed in a sandwich state due to the two-way heat transfer between the inner wall of the centrifugal casting and the mold.