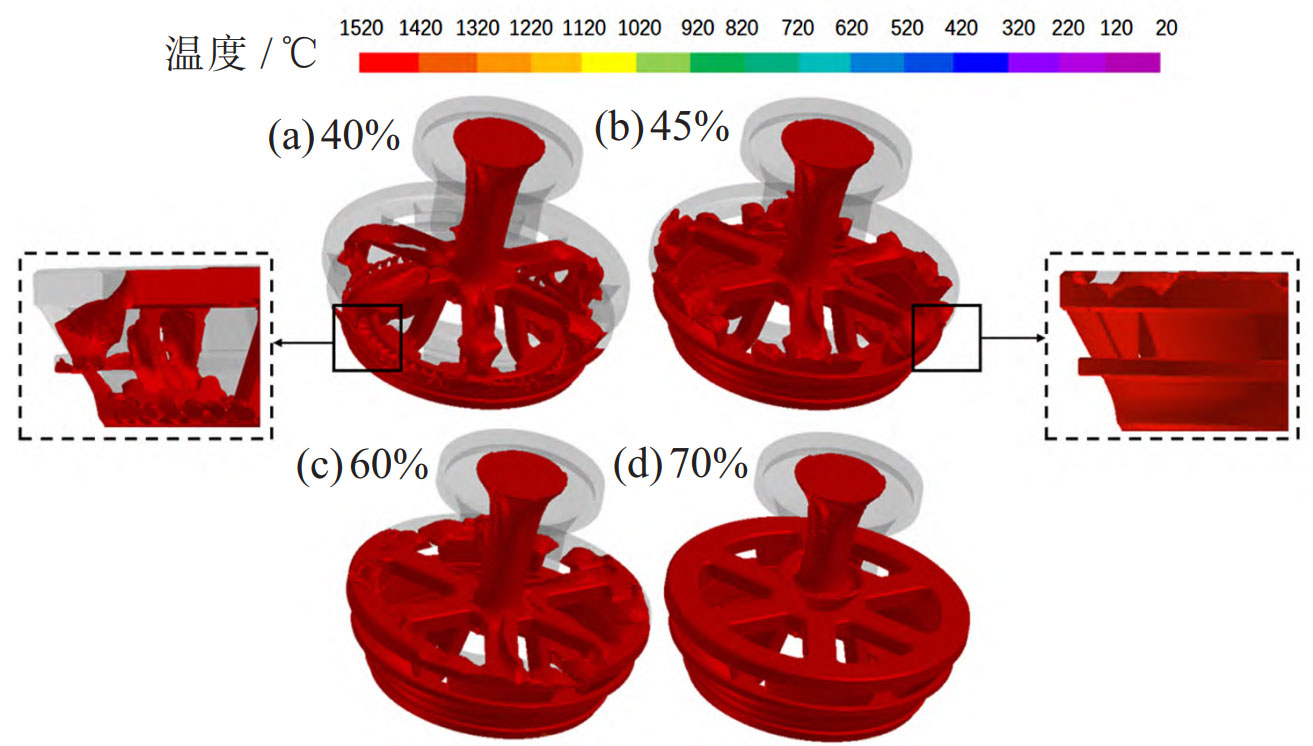

Figure 1 shows the simulation results of the initial process of precision casting for turbine guides at different filling stages. From Figure 1, it can be seen that when the filling rate is 40%, the inner ring and blade area of the turbine guide are basically filled with metal liquid, and the outer ring has a certain filling height. At this time, the metal liquid begins to flow along the transverse gate near the gate cup, and the metal liquid in the transverse gate flows into the outer ring through the riser area, which is prone to turbulence and slag accumulation at the outer ring, and may even affect the temperature and solidification fields of the inner ring and blade areas. When the filling is 45%, the metal liquid of the top transverse runner and bottom runner have completed the filling of the outer ring and flange area together. At this time, the main body of the precision casting turbine guide has been filled, and only the transverse runner, riser, and gate cup are not filled with metal liquid. However, the height of the metal liquid in each riser area varies, indicating that the metal liquid flowing through the top transverse runner and bottom inner ring is at the intersection of the outer ring and flange area during the filling process, It already has a high risk of suffocation and slag entrapment due to turbulence. When the filling rate is 60%, the riser area has completed filling, but the flow state of the metal liquid at the top of the riser area and the transverse runner is relatively disordered, which is closely related to the risk of suffocation and slag entrapment during the early filling stage. When 70% of the mold is filled, only the sprue cup remains unfilled.

From this, it can be seen that when the initial process adopts the top bottom composite method for mold filling, there is a serious turbulence phenomenon in the filling stage of the outer ring and flange, greatly increasing the risk of gas holding and slag entrapment, thereby affecting the stability and metallurgical quality of the precision casting filling process. In addition, when the filling rates are 45% and 60% respectively, the main part of the precision casting and the riser area complete the filling respectively, indicating that the metal utilization rate of the initial pouring system is seriously low, which does not comply with the principle of reducing costs and increasing efficiency.

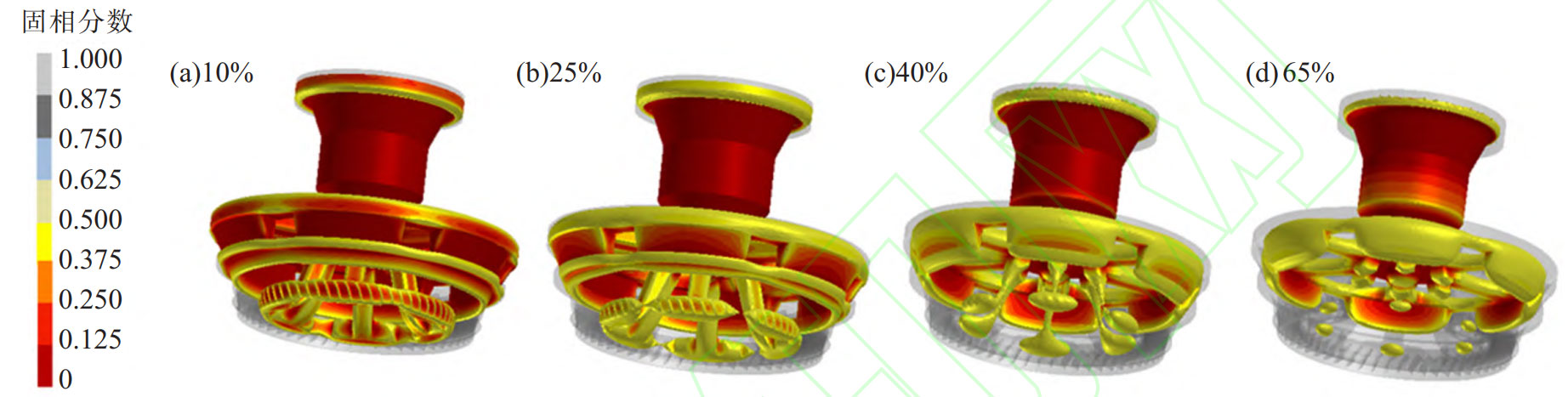

In order to better characterize and analyze the simulation results and solidification sequence of using the initial process to produce turbine guides at different solidification stages, the solidified areas were hidden, and the results are shown in Figure 2. From Figure 2, it can be seen that when the solidification rate is 10%, only the relatively thin areas of the outer ring and blade of the precision casting complete solidification; As the solidification process advances to 25%, the outer ring of the precision casting completely solidifies, and the connection area between the blade and the inner ring gradually solidifies along the direction of the bottom gate. At this point, the solidification of some areas of the inner ring is completed, and the flange area begins to gradually solidify. When the solidification rate is 40%, the main area of the precision casting has basically completed solidification, leaving only the connection area between the riser and flange and the connection area between the blade inner ring bottom gate not fully solidified. At this point, the upper auxiliary pouring system of the precision casting begins to gradually solidify. When the solidification rate is 65%, the main body of the precision casting has completely solidified, leaving only the isolated liquid phase zone formed inside the bottom gate and the upper auxiliary gating system of the precision casting not yet solidified. At this time, there is still a large amount of non solidified metal liquid in the gate cup and riser.