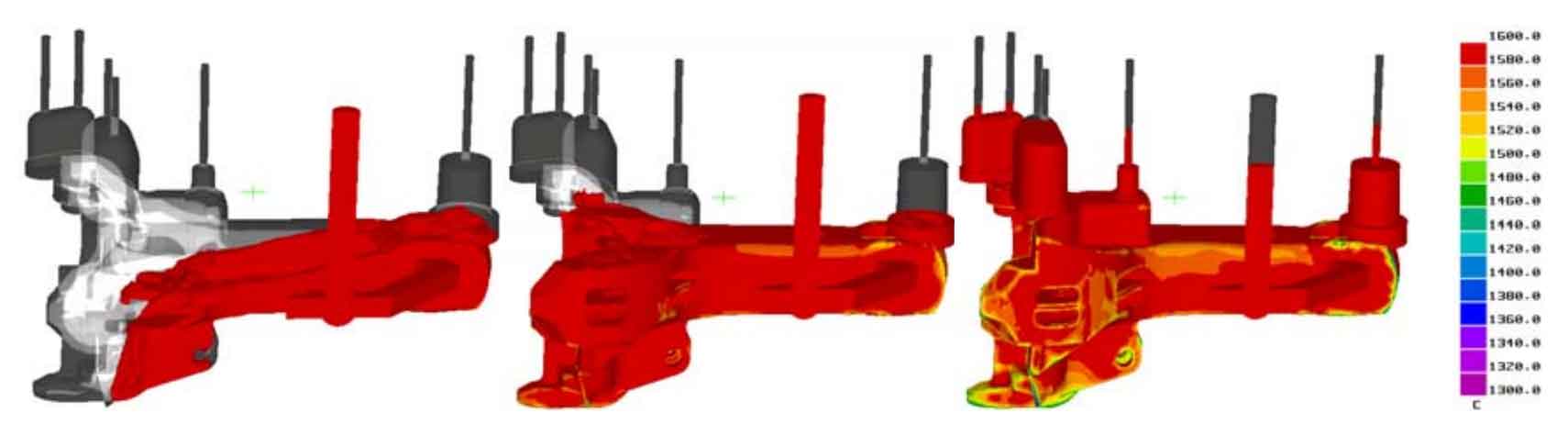

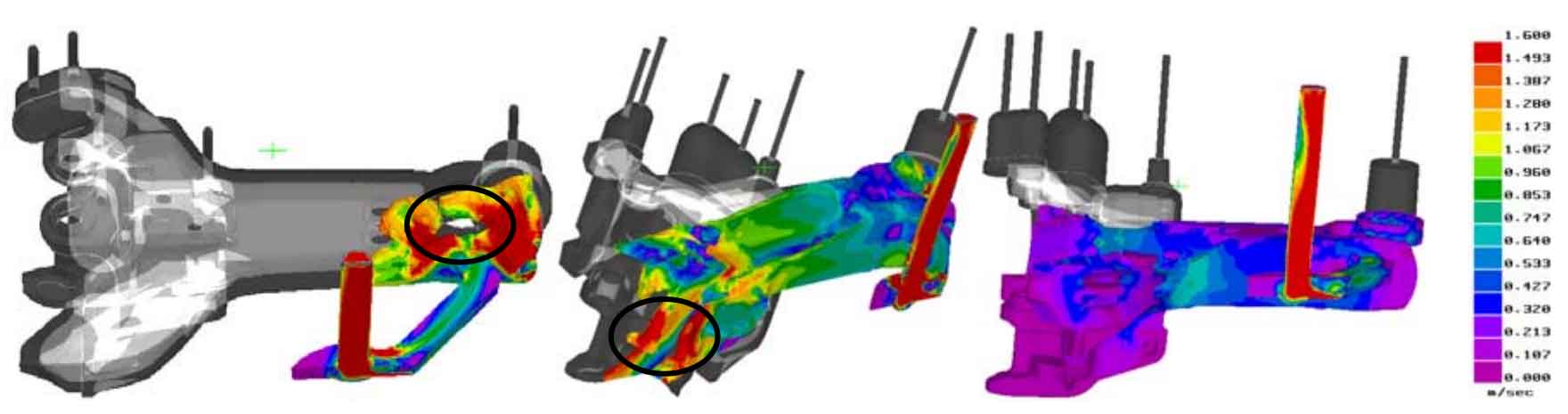

Figures 1 to 4 show the simulation analysis results of the mold filling process of hook steel castings. Figure 1 shows the analysis results of filling sequence and temperature of each part at different times in the filling process of hook body in the original casting process. It can be seen from Figure 1 that the filling process is stable, there is no obvious splash, and the fluidity of liquid metal is good. Figure 2 shows the flow velocity distribution in the filling process of the original casting process. In actual production, the reasonable flow state can make the impurities in the molten metal float up quickly, avoid air wrapping, reduce the oxidation of the molten metal, and weaken the scouring of the molten metal on the mold wall and the resulting sand flushing and slag inclusion casting defects.

It can be seen from Fig. 2 that at the initial stage of casting, the flow rate of the coupler tail pin hole facing the inner gate is large, and the liquid steel continues to fill the mold. When flowing into the coupler head, the downward impact speed is large, and if the speed is large, the sand core and mold will be impacted by the liquid steel, and the erosion will be more serious. It is very easy to form sand flushing and slag inclusion defects around the corresponding parts. After the liquid metal enters the upper mold, the overall flow rate is slightly better, and the forward impact is still large. When the liquid steel begins to enter the riser, the liquid level is stable, Conducive to the floating of impurities.

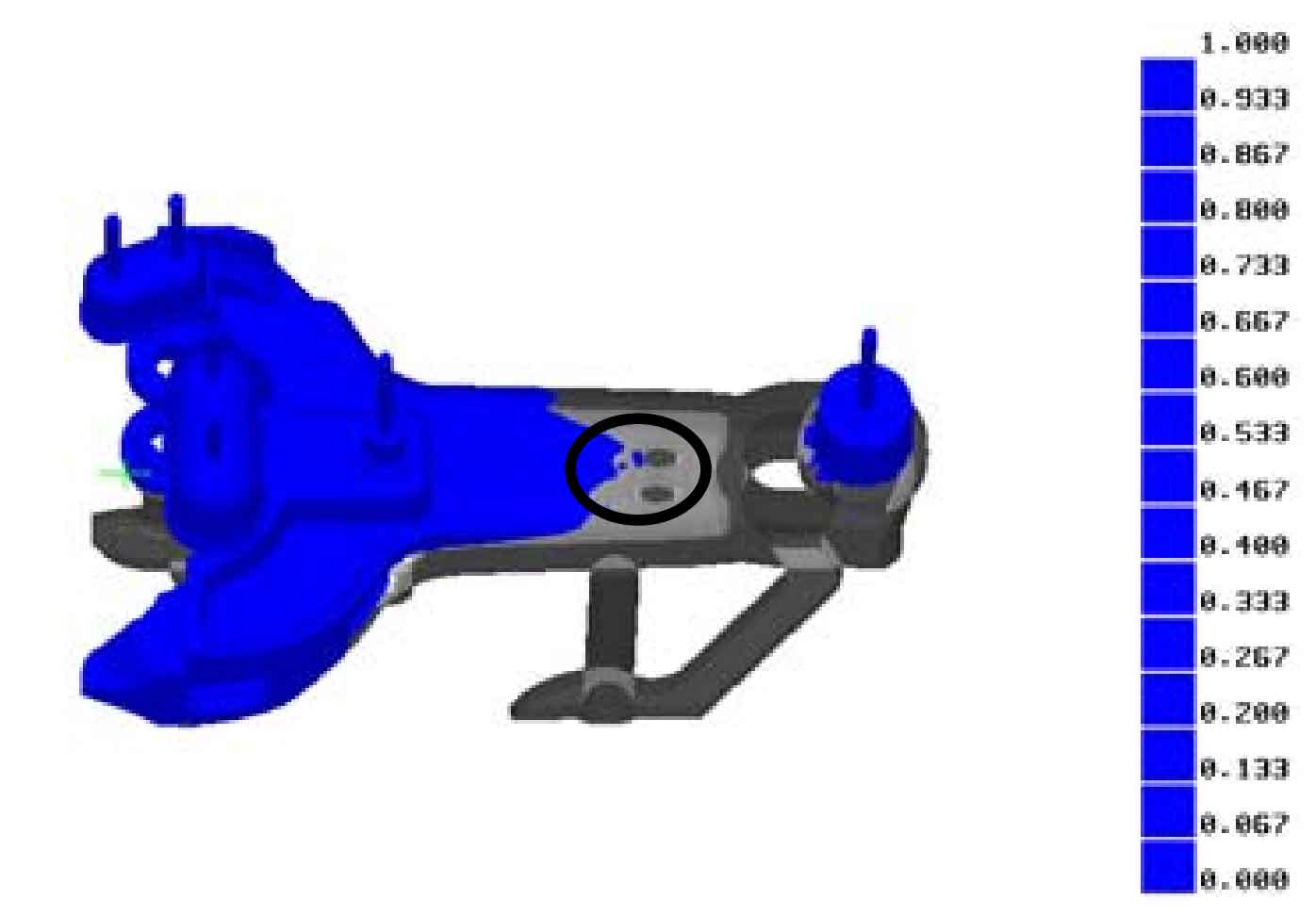

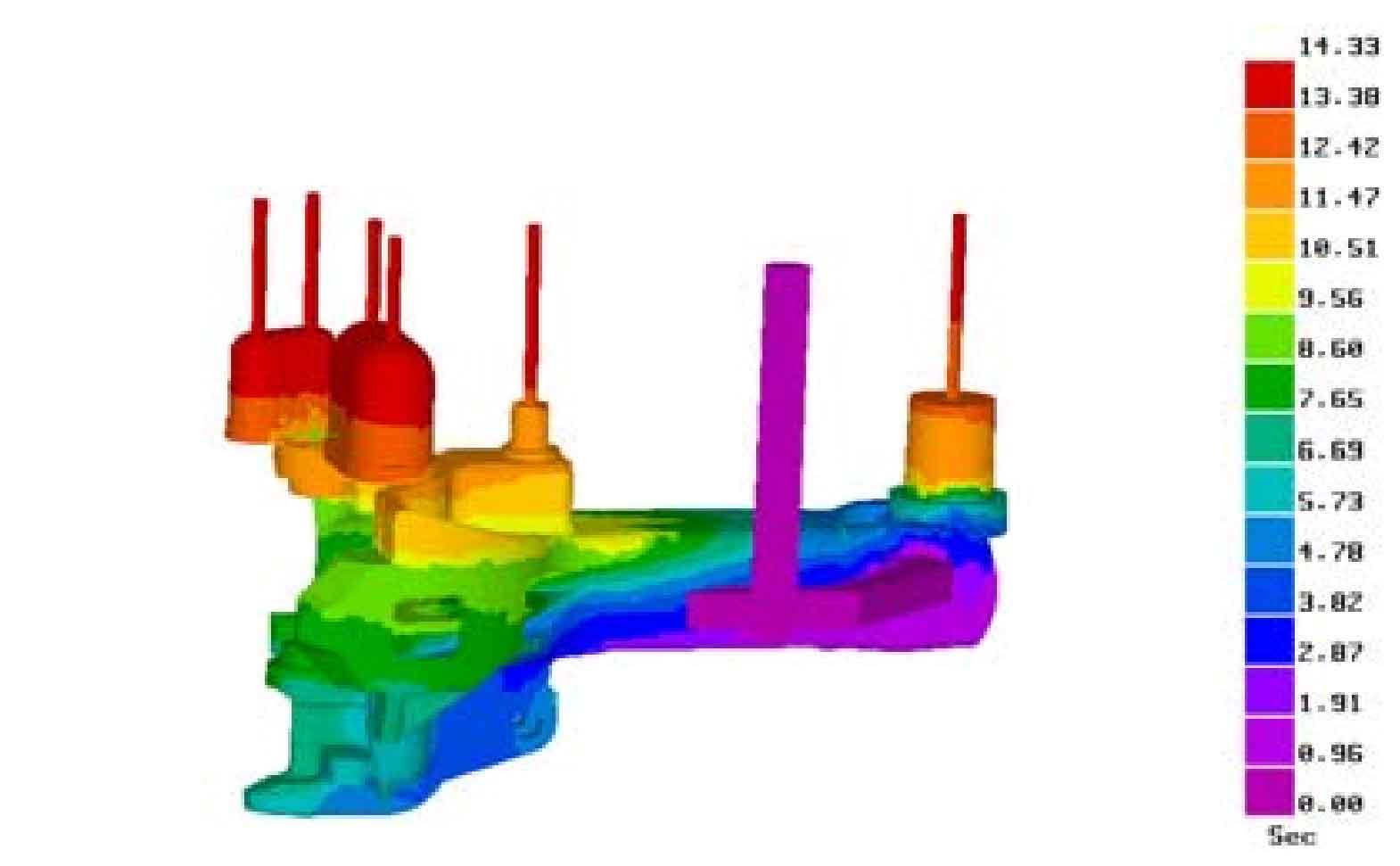

Figure 3 shows the prediction of trapped gas (internal bubbles) in the mold filling process of casting. It can be seen from the simulation results that the large plane gas on the hook body flows in a fan-shaped direction to the hook head. The large plane has a large width and a long distance, and it is easy to stay in a certain part and form pore defects. Figure 4 shows the distribution of filling time.