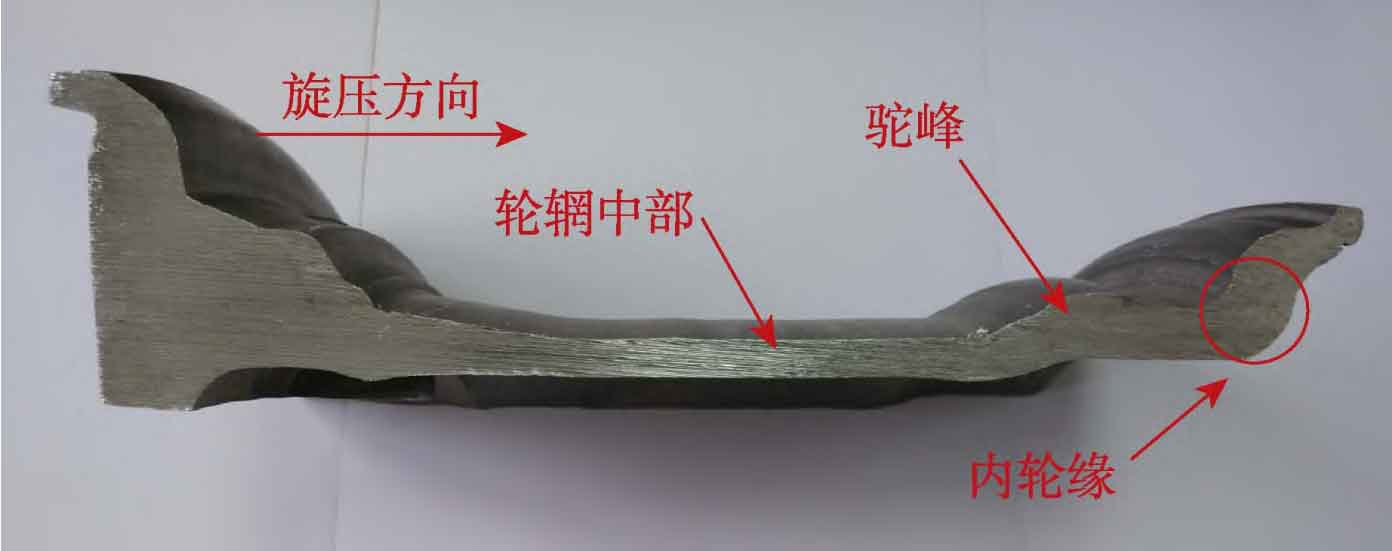

A356 alloy has good casting performance, and can obtain high strength and good plasticity after heat treatment. At present, A356 is used for aluminum alloy wheels of automobiles. Aluminum alloy wheels are manufactured by casting, forging and spinning. The casting and spinning process is a composite forming method of casting+spinning, that is, the outer part of the wheel is low-pressure casting, and the rim part is hot spinning.

The casting and spinning process of aluminum alloy wheel can refine the grain at the rim, and the metal fiber structure is streamline distributed, which improves the strength and elongation of the material, and is conducive to the lightweight of the wheel. However, the traditional (existing) spinning process has small and uneven deformation of the material at the inner rim and low performance, resulting in the inner rim cracking of the wheel under harsh road conditions. The design of the spinning die for aluminum alloy wheels is mainly studied, which is mainly described in detail from various parameters of the spinning process, thermo-mechanical coupling simulation of spinning, stress and strain, spinning pressure and manufacturing process optimization. None of the above has conducted a deep research on spinning inner flange forming. In order to improve the performance of the inner rim, an improved forming process of the inner rim is proposed. This process can improve the deformation uniformity of the inner rim and improve the mechanical properties of the inner rim.

This paper analyzes the reasons for the lack of performance at the inner rim of the cast and spun aluminum alloy wheel, and puts forward an improvement plan to improve its performance, and proposes a special spinning process for the slow feed of the special-shaped spinning wheel. The conclusions are as follows.

1) Increasing the deformation at the inner flange and improving the local deformation uniformity of the inner flange are important methods to improve the mechanical properties of the inner flange.

2) The spinning process of slowly feeding with the end shape can obtain greater plastic deformation and better deformation uniformity, and the yield strength, tensile strength and elongation of the inner flange can be increased by more than 10%.

3) The average microhardness of the area near the mandrel at the inner rim is the largest, followed by the central area, and the area near the spinning wheel is the smallest.