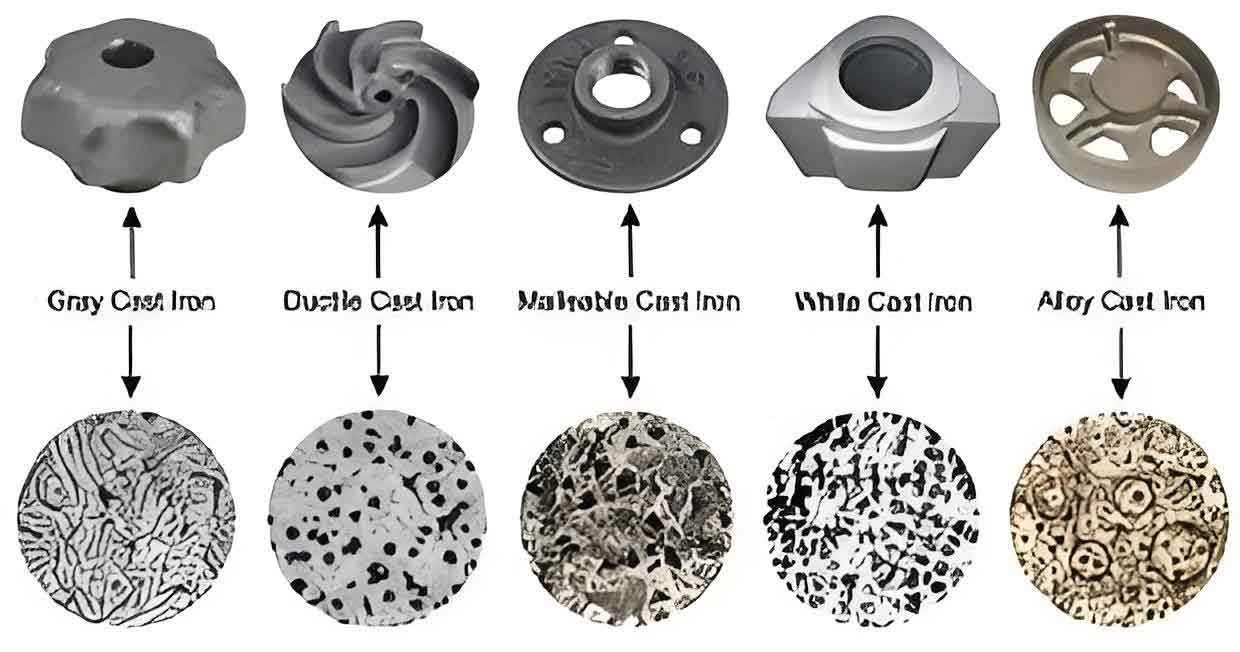

Effective casting design is crucial to optimize the performance, quality, and manufacturability of cast iron components. Here are key considerations for designing castings with gray, white, ductile, and malleable cast irons:

1. Gray Cast Iron

- Wall Thickness:

- Uniform wall thickness minimizes internal stresses and reduces the risk of casting defects such as warping or cracking.

- Avoid abrupt changes in thickness to ensure uniform cooling.

- Ribs and Fillets:

- Incorporate ribs to strengthen thin sections and fillets to avoid sharp corners, which can concentrate stress and lead to cracking.

- Draft Angles:

- Include adequate draft angles (typically 1-3 degrees) to facilitate easy removal from the mold without damaging the casting.

- Cooling Rates:

- Ensure controlled cooling rates to avoid excessive residual stresses and achieve the desired microstructure.

- Core Design:

- Use well-designed cores to create internal cavities and complex shapes, ensuring they are securely positioned and properly vented.

2. White Cast Iron

- Section Thickness:

- Design with thicker sections to ensure the entire casting solidifies quickly, promoting the formation of hard cementite.

- Avoid thin sections which might not solidify uniformly, leading to incomplete hardening.

- Chills:

- Use chills (metal inserts) to control cooling rates and promote uniform solidification, reducing the risk of cracking and other defects.

- Shape Complexity:

- Minimize sharp corners and intricate shapes to reduce stress concentrations, as white cast iron is very brittle.

- Draft Angles:

- Provide sufficient draft angles to aid in the removal of the casting from the mold.

3. Ductile Cast Iron

- Uniform Wall Thickness:

- Ensure uniform wall thickness to avoid hot spots, which can lead to shrinkage defects and uneven mechanical properties.

- Gradual transitions between sections to avoid stress concentration.

- Riser Placement:

- Position risers to feed molten metal to the casting as it cools and solidifies, reducing shrinkage cavities and porosity.

- Gating System:

- Design an efficient gating system to ensure smooth and turbulence-free flow of molten metal, reducing defects such as cold shuts and inclusions.

- Draft Angles:

- Adequate draft angles (typically 1-2 degrees) are necessary to ensure easy mold release.

- Stress Relievers:

- Use fillets and radii to minimize sharp corners and stress risers, enhancing the mechanical performance of the casting.

4. Malleable Cast Iron

- Section Thickness:

- Maintain uniform section thickness to ensure even cooling and avoid internal stresses and defects.

- Avoid abrupt changes in thickness to minimize stress concentration.

- Ribbing and Filleting:

- Use ribs to support thin sections and fillets to reduce stress concentration at corners.

- Draft Angles:

- Include sufficient draft angles (typically 1-3 degrees) to facilitate the removal of the casting from the mold without damage.

- Core Design:

- Ensure proper core design to create complex shapes and internal features, and prevent core shifting and related defects.

- Cooling Rates:

- Control cooling rates to achieve the desired microstructure and mechanical properties, avoiding rapid cooling that can lead to brittleness.

General Casting Design Guidelines

- Material Selection:

- Choose the appropriate type of cast iron based on the required mechanical properties and application (e.g., gray iron for good machinability, white iron for wear resistance, ductile iron for high strength and ductility).

- Solidification and Shrinkage:

- Account for solidification shrinkage by designing risers and feeders to supply molten metal as the casting cools.

- Ensure proper venting to allow gases to escape, preventing porosity and other defects.

- Surface Finish:

- Consider the surface finish requirements, as different types of cast iron exhibit different levels of finish quality.

- Tolerances and Machining Allowances:

- Design with appropriate tolerances and machining allowances to ensure that the final dimensions meet specifications after any required machining operations.

- Quality Control:

- Implement quality control measures such as non-destructive testing (NDT) to inspect for internal defects and ensure casting integrity.

Summary of Key Design Considerations for Each Type of Cast Iron

| Cast Iron Type | Key Design Considerations |

|---|---|

| Gray Cast Iron | Uniform wall thickness, ribs and fillets, draft angles, controlled cooling rates, core design. |

| White Cast Iron | Thicker sections, use of chills, simple shapes, adequate draft angles. |

| Ductile Cast Iron | Uniform wall thickness, riser placement, efficient gating system, draft angles, stress relievers. |

| Malleable Cast Iron | Uniform section thickness, ribbing and filleting, draft angles, core design, controlled cooling rates. |

By carefully considering these design aspects, engineers can optimize the performance and manufacturability of cast iron components, ensuring they meet the specific requirements of their intended applications.