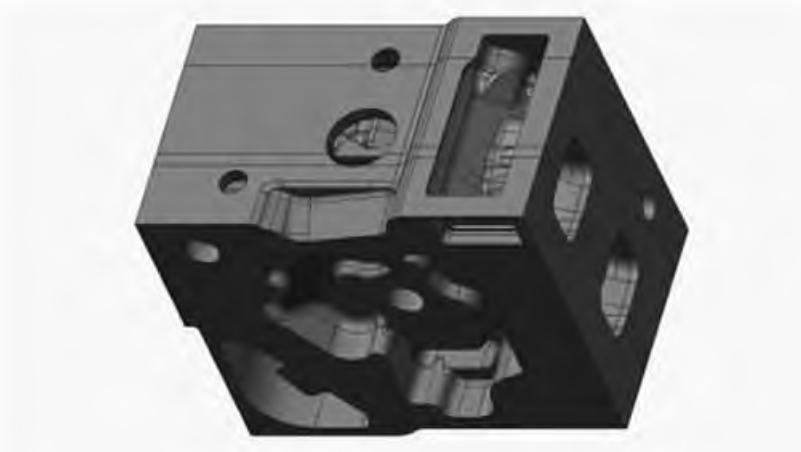

This research details the comprehensive casting process development for an EN-GJS-400-18-LT gearbox body (EN 1563), weighing 162 kg with critical internal quality requirements. The component features complex geometry (961 mm × 596 mm × 252 mm) demanding stringent radiographic (RT) and ultrasonic (UT) inspection compliance. Our methodology integrated initial casting process design with Procast simulation and iterative physical trials to eliminate defects.

Casting Process Design Fundamentals

The casting process employed a horizontal parting through the gearbox centerline using 1,140 mm × 1,020 mm universal flasks. Four resin-bonded sand cores formed internal cavities and lifting points. Core assembly sequencing was critical: Core #1 and #2 nested into Core #3 before placement in the drag, while Core #4 featured a 20-mm sand-backing zone for secure positioning. A closed top-gating system ensured rapid filling and slag trapping with a choke at the ingates. Ingates connected to flange surfaces to facilitate cleaning. The cross-sectional area ratio was optimized as:

$$ F_{\text{直}} : F_{\text{横}} : F_{\text{内}} = 2.04 : 1.64 : 1 $$

Pouring parameters were established through empirical calculations:

$$ t_{\text{pour}} = k \cdot \sqrt[3]{W_{\text{casting}}} $$

$$ t_{\text{pour}} = 25 \pm 2 \text{ seconds at } T_{\text{pour}} = 1,350^\circ \text{C} – 1,370^\circ \text{C} $$

where \( k \) = empirical constant (0.85 for ductile iron), \( W_{\text{casting}} \) = casting weight (162 kg).

| Process Parameter | Value |

|---|---|

| Material | EN-GJS-400-18-LT |

| Part Weight | 128.8 kg |

| Casting Weight | 162 kg |

| Pouring Temperature | 1,350°C – 1,370°C |

| Pouring Time | 25 s |

| Gating Ratio (Sprue:Runner:Ingate) | 2.04:1.64:1 |

Procast Simulation-Driven Refinement

Initial Procast analysis predicted shrinkage at isolated thermal nodes due to abrupt section changes. The solidification time (\( t_{\text{solid}} \)) at hot spots exceeded the critical feeding window:

$$ t_{\text{solid}} = C \left( \frac{V}{A} \right)^n $$

where \( C \) = Chvorinov constant, \( V \) = volume, \( A \) = surface area, \( n \) ≈ 2. To counteract this, chromium steel chills and insulating sleeves were strategically placed at critical coordinates to accelerate solidification and extend feeding. Chill sizing followed:

$$ M_{\text{chill}} = \frac{M_{\text{casting}}}{3} $$

where \( M \) = modulus (Volume/Surface Area).

First Production Trial: Defect Analysis

Initial trials validated dimensional accuracy but revealed three critical issues:

| Defect Location | Type | RT Level | Root Cause |

|---|---|---|---|

| Lifting Lug Interface | Shrinkage Porosity | 4 | Insufficient cooling at isolated thermal mass |

| External Rib Junction | Shrinkage Porosity | 3 | |

| Upper Surface | Surface Blowholes | N/A | Gas entrapment in late-filling zones |

Additionally, low-temperature Charpy impact values (8-10 J at -20°C) below EN 1563 requirements were traced to excessive silicon content (2.2-2.5 wt%), increasing ductile-to-brittle transition temperature.

Process Optimization and Validation

The casting process was modified with three corrective actions:

- Enhanced Cooling: Added cylindrical steel chills at shrinkage locations using the relationship:

$$ Q_{\text{extracted}} = h \cdot A \cdot (T_{\text{metal}} – T_{\text{chill}}) \cdot t $$ - Improved Filling Dynamics: Increased pouring temperature to 1,400°C and tilted the mold 3° toward the gating system to accelerate flow in distant sections.

- Metallurgical Adjustment: Reduced Si content to 2.0-2.2 wt% to enhance low-temperature toughness.

Final trial results confirmed success:

| Quality Metric | Result | Standard |

|---|---|---|

| RT/UT Inspection | 100% Level 1 at critical zones | ISO 4990 |

| Surface Quality | Zero gas defects | Visual inspection |

| Charpy Impact (-20°C) | 10-14 J | EN 1563 |

Conclusion

This casting process optimization demonstrates that integrating simulation with targeted physical validations ensures defect-free production of high-integrity ductile iron castings. Key success factors include:

- Precise chill placement governed by thermal modulus calculations

- Dynamic control of filling through temperature and tilt adjustments

- Silicon content optimization balancing graphitization and toughness

The methodology establishes a replicable framework for complex castings requiring stringent internal quality standards, proving that a robust casting process is achievable through systematic iteration between virtual and physical validation.