Abstract:

This study focuses on the optimization of casting process parameters for an aluminum alloy cylinder body (specifically ZL114A alloy). By employing the Taguchi design method for orthogonal testing and gray relational analysis, the optimal combination of pouring temperature, filling and pressurizing speed, holding pressure, and holding time was determined. The results indicate a significant improvement in porosity and solidification time compared to the initial process, validating the feasibility and effectiveness of the optimized parameters. This optimization contributes to enhanced casting quality, mechanical properties, production efficiency, and product qualification rates.

1. Introduction

The aluminum alloy cylinder body, particularly the ZL114A type, is widely utilized in the automotive industry due to its excellent casting performance, high temperature resistance, corrosion resistance, high strength, and lightweight characteristics. However, achieving high-quality castings requires precise control of casting process parameters. In this study, we aimed to optimize the casting process parameters for the ZL114A aluminum alloy cylinder body to minimize porosity and reduce solidification time.

2. Initial Process Analysis

2.1 Alloy Composition and Thermophysical Properties

The ZL114A alloy, an Al-Si series casting alloy, was selected for this study. Table 1 outlines the alloy composition, while Table 2 presents the thermophysical properties obtained using JMatPro software.

| Table 1: Alloy Composition |

|---|

| Element |

| Si |

| Cu |

| Mg |

| Mn |

| Fe |

| Ni |

| Zn |

| Ti |

| Sn |

| Pb |

| Al |

| Table 2: Thermophysical Properties of ZL114A Alloy |

|---|

| Property |

| Density (g/cm³) |

| Melting Point (°C) |

| Thermal Conductivity (W/mK) |

| Specific Heat (J/g·°C) |

2.2 Initial Process Parameters

Based on the casting characteristics of ZL114A alloy, the initial process parameters were selected as follows: pouring temperature of 680°C, filling and pressurizing speed of 2.4 kPa/s, holding pressure of 75 kPa, and holding time of 260 s. Numerical simulations using ProCAST predicted a porosity rate of 1.795% and a solidification time of 499.7 s under these conditions.

3. Orthogonal Testing Based on Taguchi Method

To optimize the casting process parameters, an L16(44) orthogonal test design was employed, considering four factors: pouring temperature (A), filling and pressurizing speed (B), holding pressure (C), and holding time (D). Each factor had four levels, as detailed in Table 3.

| Table 3: Factor Levels for Orthogonal Test |

|---|

| Factor |

| Pouring Temp. (A) /°C |

| Filling Speed (B) /kPa·s⁻¹ |

| Holding Press. (C) /kPa |

| Holding Time (D) /s |

4. Gray Relational Analysis

Gray relational analysis (GRA) was used to evaluate the correlation between the process parameters and the target response values (porosity and solidification time). The steps involved in GRA include calculating the gray relational coefficient, determining the gray relational grade, and conducting range analysis.

4.1 Calculation of Gray Relational Coefficient

The gray relational coefficient ξi(k) for each test group and target value was calculated using the formula:

ξi(k) = (Δmin + ρΔmax) / (Δoi(k) + ρΔmax)

where Δmin is the minimum difference between the ideal and actual values, Δmax is the maximum difference, Δoi(k) is the difference for the ith test group and kth target value, and ρ is the resolution coefficient (typically taken as 0.5).

4.2 Determination of Gray Relational Grade

The gray relational grade γi, which reflects the overall correlation between the process parameters and target response values, was calculated by averaging the gray relational coefficients:

γi = 1/n Σξi(k)

4.3 Range Analysis

Range analysis was conducted to determine the weight of influence of each process parameter on the gray relational grade. The range R for each factor was calculated as the difference between the maximum and minimum gray relational grades at different levels.

Table 4: Range Analysis Results

| Factor | Gray Relational Grade Range (R) |

|---|---|

| Pouring Temp. (A) | 0.0987 |

| Filling Speed (B) | 0.0580 |

| Holding Press. (C) | 0.0775 |

| Holding Time (D) | 0.0569 |

5. Optimized Process Parameters

Based on the GRA results, the optimal combination of process parameters was determined as follows: pouring temperature of 700°C, filling and pressurizing speed of 1.2 kPa/s, holding pressure of 65 kPa, and holding time of 220 s.

6. Numerical Simulation and Experimental Verification

6.1 Numerical Simulation Results

Numerical simulations were conducted to compare the initial and optimized process parameters. The results showed a porosity rate of 1.463% and a solidification time of 481.2 s for the optimized process, representing a 18.5% reduction in porosity and a 3.7% decrease in solidification time compared to the initial process.

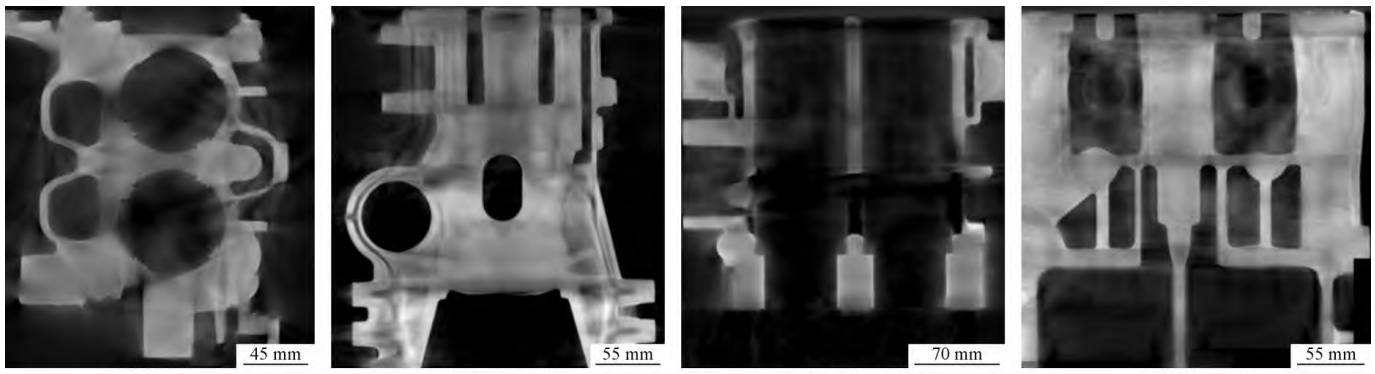

6.2 Experimental Verification

To validate the optimized process parameters, engine cylinder body castings were produced and tested. The castings exhibited a complete appearance with clear edges and corners. No surface defects such as cold shuts, cracks, shrinkage cavities, or penetrating defects were observed. CT scanning confirmed the absence of internal defects such as inclusions, cracks, or excessive shrinkage cavities.

Mechanical testing of the castings showed an average yield strength of 216.4 MPa and an average tensile strength of 235.2 MPa, meeting the requirements for engine cylinder body service conditions.

7. Conclusion

This study successfully optimized the casting process parameters for the ZL114A aluminum alloy cylinder body using the Taguchi design method and gray relational analysis. The optimized process parameters resulted in a significant reduction in porosity and solidification time, leading to improved casting quality and mechanical properties. The proposed methodology can be applied to other casting processes to enhance production efficiency and product qualification rates.