Ductile iron castings have paste solidification characteristics and are easy to produce dispersed shrinkage porosity. If there is high sand mold rigidity, appropriate modulus of ductile iron castings, make full use of eutectic expansion pressure to prevent shrinkage porosity. In general, the riser feeding distance can not be considered.

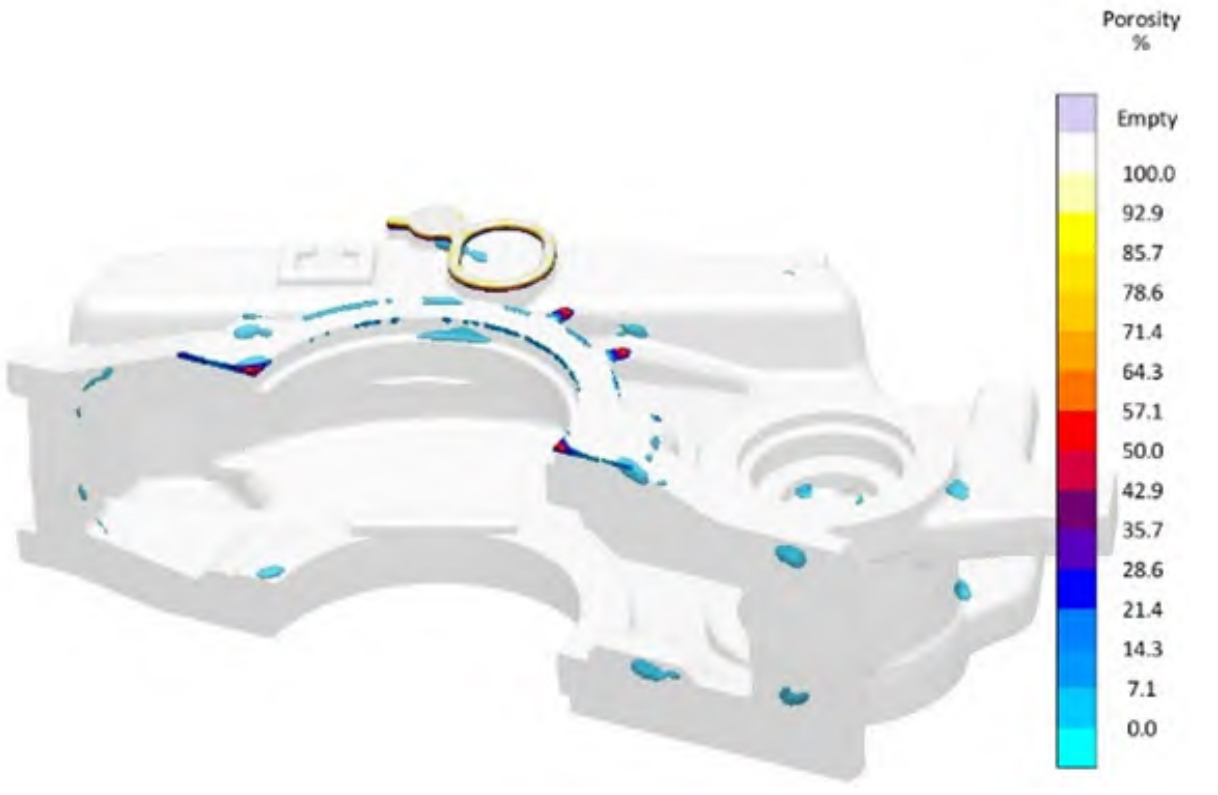

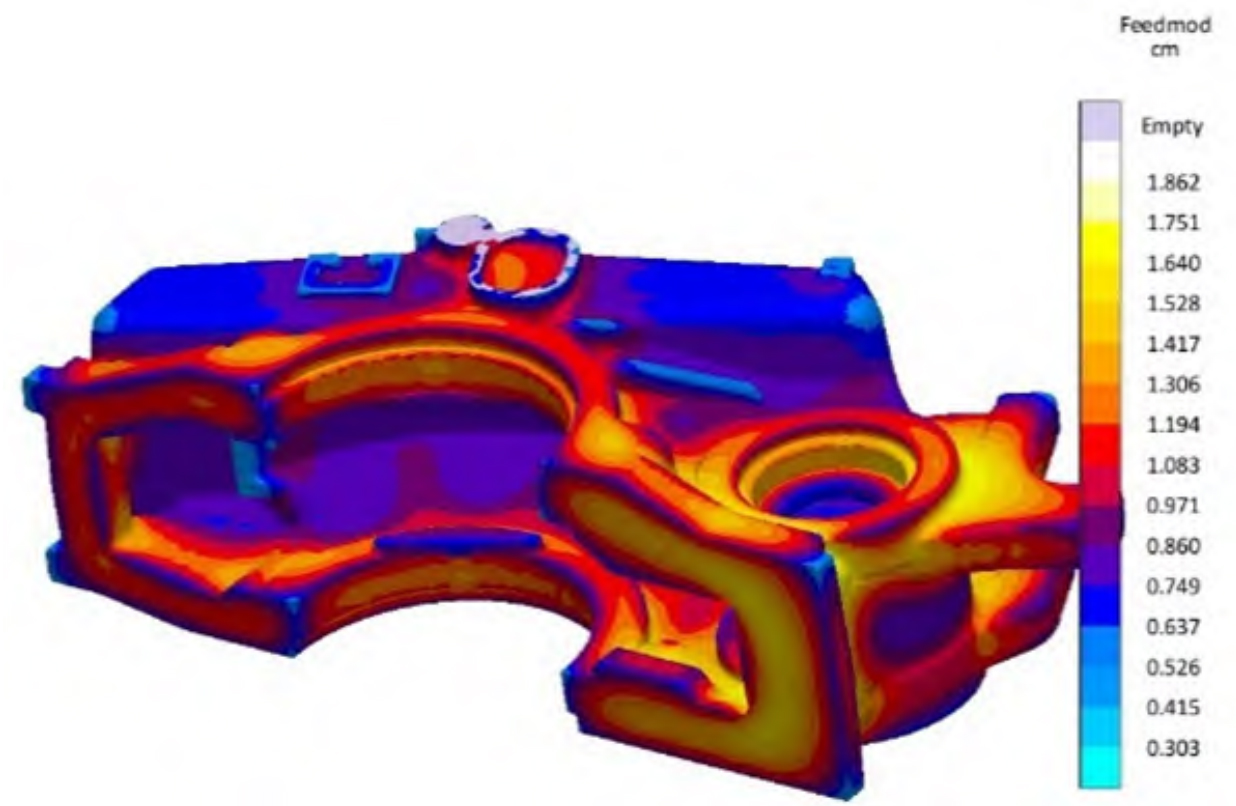

The structure of the lower box of ductile iron castings for railway gear boxes is more complex than that of the upper box, and the casting difficulty is greater than that of the upper box. The solidification simulation calculation and analysis of the lower box ductile iron castings are carried out using MAGMA software. Figure 1 shows the simulation of shrinkage and porosity distribution of ductile iron castings. It can be seen that there are super problems of shrinkage and porosity in the key areas of the gear box, and there is shrinkage on the top surface of ductile iron castings. The volume expansion generated by graphite precipitation alone cannot meet the quality requirements for feeding of ductile iron castings. Figure 2 shows the simulation of the thermal modulus distribution of ductile iron castings. It can be seen that the thermal modulus is 0.33~1.86 cm, which does not meet the conditions for self-expansion and feeding, and requires the use of risers for liquid feeding.