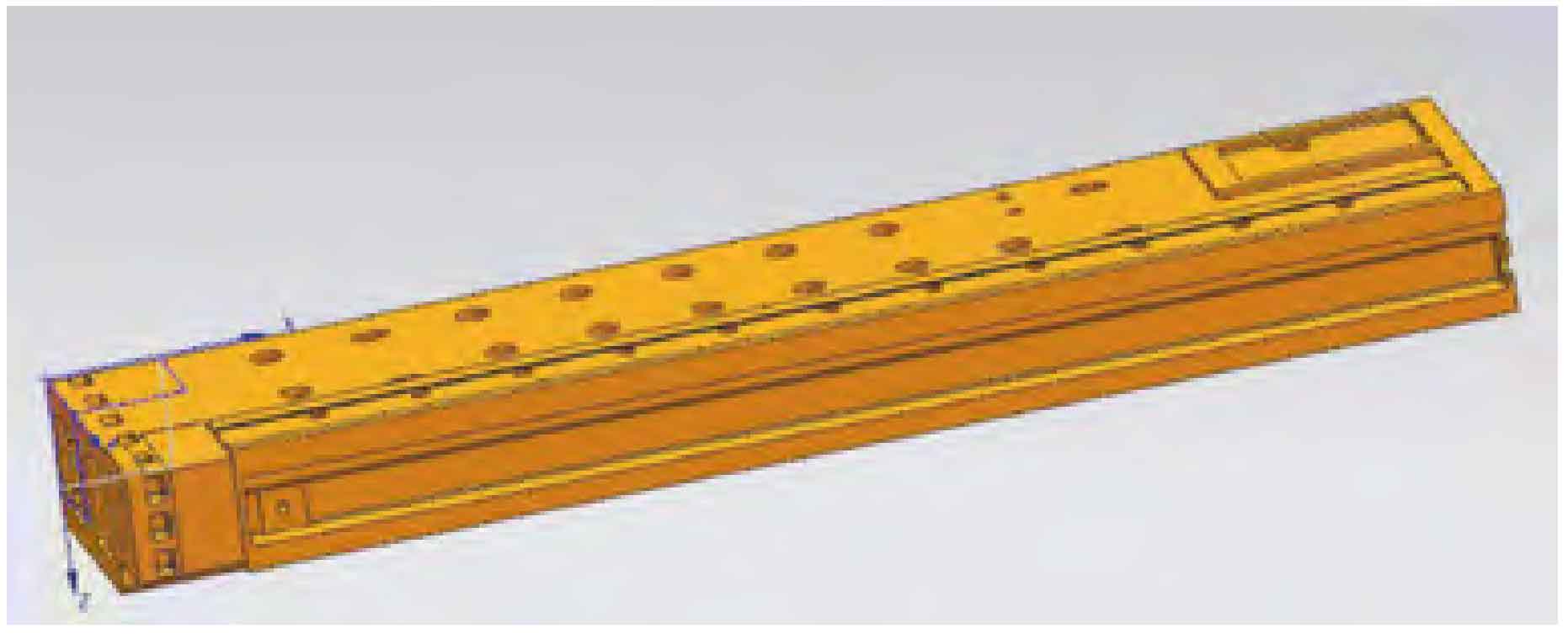

The column of a large CNC vertical lathe (hereinafter referred to as “vertical lathe”) is a key basic component of the machine tool. The column mainly supports and stabilizes the components involved in cutting, such as the vertical lathe beam, tool rest body and ram, to meet the Z-direction movement of the beam along the column guide rail, and to work under the adverse conditions of indirectly withstanding cutting force, vibration, temperature changes, etc. In order to meet the processing requirements of CNC vertical lathe, the vertical lathe column is required to have high enough component strength and stiffness, good vibration resistance and thermal deformation resistance, so its structural rigidity, vibration reduction performance, guide rail surface hardness and other requirements are high, making the process design and manufacturing of vertical lathe column difficult.

The vertical lathe column produced by the above modeling, box fastening, pouring and other programs has no shrinkage cavity, porosity, crack and other casting defects after processing. The metallographic structure and mechanical properties of the test bar and the body test meet the requirements of GB/T 9439-2010 and GB/T 7216-2009. At present, mass production has been carried out according to this scheme.

Due to the long size, complex internal structure, multiple rib plates and delamination, long filling stroke of molten iron and long cooling time of castings, the column of large CNC vertical lathe is easy to produce casting defects such as cold shut, shrinkage cavity, shrinkage porosity, air hole, crack, and mechanical property substandard. For the production of such large castings, process analysis and optimization shall be carried out in combination with the actual production conditions, production capacity, technical requirements of parts, structural characteristics and other factors, and reasonable casting process plan shall be determined. At the same time, the production process shall be strictly controlled to ensure that the quality of castings meets the design requirements.