1. Floating core

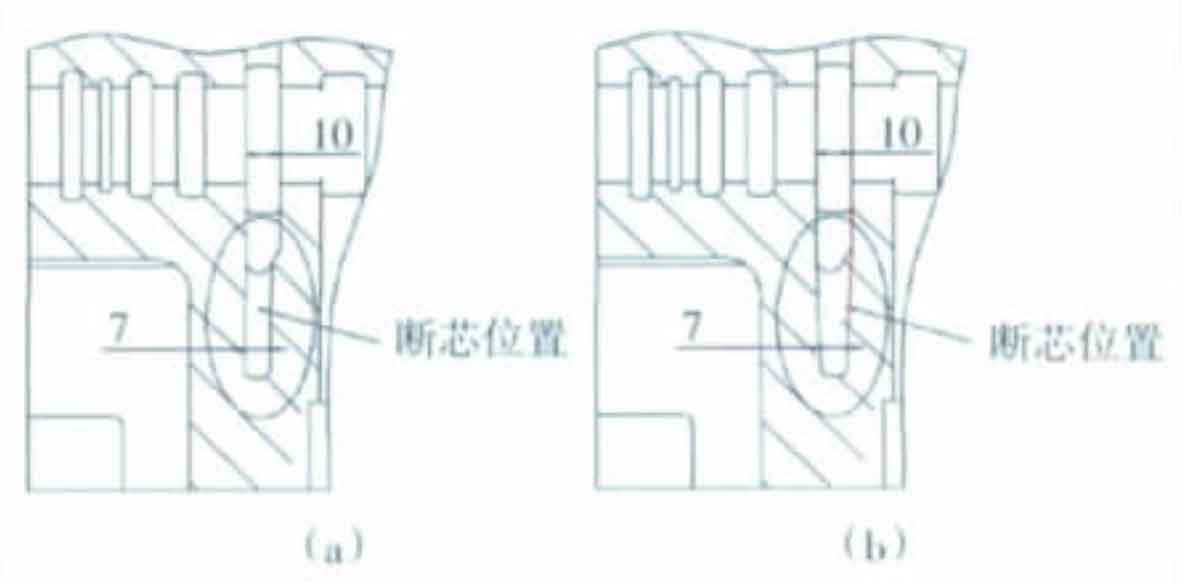

There are regular pits on the upper surface of nodular cast iron. After dissecting the nodular cast iron, it is confirmed that the thin and flat oil cavity sand core floats to the upper surface of the cavity after breaking. The defect condition is shown in Figure 1. The main reasons for this defect are: first, it is caused by the structural design of nodular iron castings, as shown in Figure 2 (a). Here is the transition between the flat deep oil cavity with thickness of 7 mm and depth of 30 mm and the flat cavity with thickness of 10 mm. The fillet radius is only 2 mm. In the process of making and ejecting the sand core, the friction resistance is large, which is easy to produce internal stress and cracks at the junction of the fillet; Second, during pouring, high-temperature molten iron enters from the top of the mold cavity and erodes the sand core.

According to the above analysis, the structural design and gate system of nodular iron castings were improved respectively. In terms of the structure of nodular iron castings, the end of the 10mm oil chamber is directly tapered to the end of the 7mm oil chamber, increasing the slope of the side of the oil chamber, so as to reduce the friction resistance of the sand core in the demoulding process. The improved design is shown in Figure 2 (b). In terms of pouring system, the top pouring is changed into step pouring. The purpose is to make the molten iron enter the mold cavity from the bottom pouring sprue in the early and middle stages of pouring, so as to ensure stable mold filling and eliminate the erosion effect of molten iron on the sand core. At the end of pouring, the molten iron enters the mold cavity through the riser, so that the molten iron in the riser is in a high temperature state and ensure the feeding effect of nodular iron castings. The improved process is shown in Figure 3.

2. Deformation

Through anatomical examination, it is found that the maximum straightness deviation of the axis of 5 valve holes of nodular iron castings in the up-down direction of the parting surface has reached 2mm. The main reasons for this deformation are as follows: first, there is a 0.5mm box closing gap between the core head on the upper surface of the sand core assembly and the molding sand; Second, green molding sand has concession. In the process of pouring and solidification, the sand core will produce the above deformation under the buoyancy of high-temperature molten iron. In order to solve this problem, two improvement measures are taken: one is to add core bone in valve hole sand core; Second, change the contact between the core head and molding sand into the contact between the core head and the core shell, and stick it with adhesive.

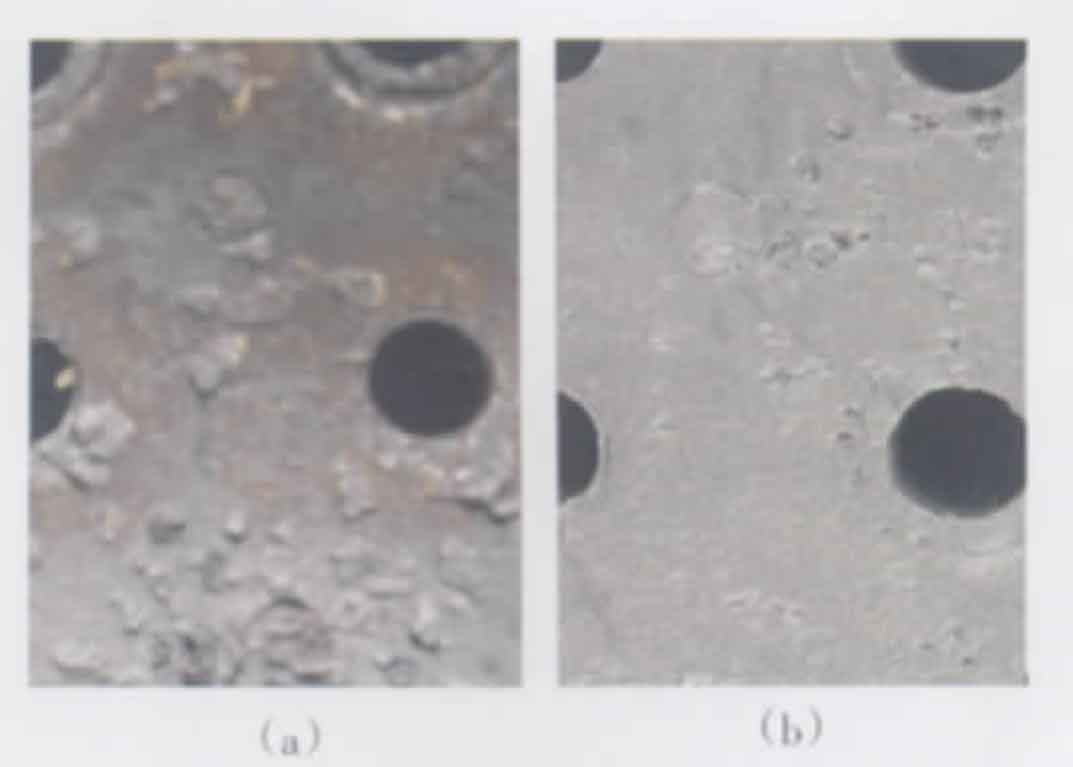

3. Hemp pit

There are pitting defects of different sizes and uneven distribution on the upper surface of nodular iron castings, and there are also a few on the side close to the upper surface. The depth of the defect is generally 2 ~ 3 mm. The defect state is shown in Fig. 4 (a). The main reasons for this defect may be:

① The upper shell sand core is made of ordinary coated sand, and the fire resistance of the coating and coated sand is not high. Under the baking of high-temperature molten iron, the sand core coating and the surface of the sand core are sintered and peeled off, turning into slag and floating on the surface of the molten iron;

② The gas produced by the sand core in the last stage of mold filling can not be discharged from the mold cavity, but remains on the upper surface of the mold cavity and adsorbs with the slag.

Based on this analysis, the following improvement measures are taken:

① Select ha high temperature resistant coating with better performance;

② Change the coated sand used for the upper shell sand core to the same coated sand as the valve body sand core.

③ An exhaust hole is added on the sand core of the upper shell.