Through testing, the actual chemical composition of molten iron is: w (c) 3.35%, w (SI) 2.14%, w (MN) 0.77%, w (P) <0.03%, w (s) 0.08%. It can be seen that all elements meet the process requirements. Among them, CE is greater than 4.0%, and the amount of W (c) and w (SI) is partial to the upper limit of the process. Tracing back to other models produced in the same batch, there is no shrinkage casting defect. Therefore, the influence of small graphite expansion caused by low CE is excluded.

Under the condition that the existing process remains unchanged, 20 pieces of gray cast iron are trial produced and poured at low temperature (1375 ℃). There are shrinkage defects in both finish turning and flaw detection. Therefore, the influence of large liquid shrinkage caused by high pouring temperature can be eliminated.

The shrinkage and feeding characteristics of gray cast iron during solidification are shown in Figure 1. Before gray cast iron cools and solidifies to equilibrium point P, it must be fed externally, and the difference between self replenishment and deficiency of gray cast iron itself must be supplemented by riser or gating system; When reaching the equilibrium point P, on the macro level, the liquid iron in the cavity will no longer produce volume loss. No matter whether the feeding channel between the riser and gray cast iron is unblocked, the gray cast iron will no longer pump the liquid iron to the riser, and the feeding effect of the riser will be stopped; After the equilibrium point P, the gray cast iron enters the stage of internal self feeding. As long as the shrinkage per unit time is no longer greater than expansion, the gray cast iron will not produce shrinkage casting defects.

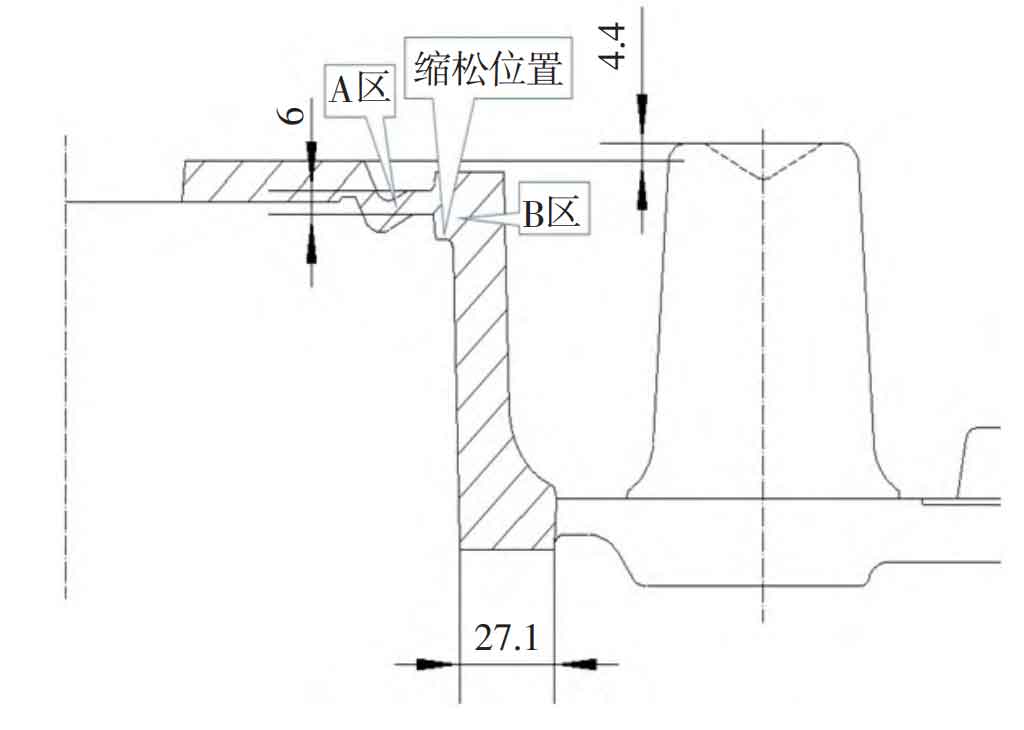

Therefore, the structure of the gray cast iron of the brake drum is analyzed (as shown in Figure 2). The wall of the gray cast iron in Zone A is thin, the temperature drops quickly and the shrinkage is large. During solidification, the molten iron in zone B needs to be replenished. The height difference between the riser and the gray cast iron is only 4 mm, which has a poor replenishment effect on zone B, while the wall thickness difference between zone B and other areas is small. During solidification, it has been close to or exceeded the equilibrium point, and the molten iron in the mold cavity cannot self replenish and shrink zone B, Finally, shrinkage porosity is formed in this area.

The analysis shows that the hot joints of gray cast iron in the brake drum are distributed on the top circumference, with a large range, far from the riser, and the insufficient feeding capacity of the riser are the main reasons for the shrinkage and looseness of the root of the inner circle at the small end.