Abstract: This paper delves into the formation mechanism of micro-cracks in thick and complex high manganese steel castings, using a finished ZGMn13 high manganese steel casting from a factory as the research subject. By analyzing the segregation of alloy elements, phase diagrams, and utilizing metallographic microscopes and scanning electron microscopes (SEM), it was discovered that micro-cracks distribute along grain boundaries, with a significant enrichment of inclusions, carbides, and low-melting-point phosphorus eutectics in the vicinity of these cracks. The tensile stress during solidification of the casting initiates micro-cracks at these oxides, carbides, and low-melting-point phosphorus eutectics. Therefore, the tensile stress during solidification and the presence of these inclusions are the primary reasons for the formation of micro-cracks in thick and complex high manganese steel castings.

1. Introduction

High manganese steel exhibits rapid work hardening on its surface under significant impact loads, maintaining its unique wear resistance [1]. Due to these special properties, high manganese steel castings are widely used in various industries such as railways, mining, and military applications. However, the linear contraction value of high manganese steel (2.4% to 3%) is much larger than that of carbon steel, and its thermal conductivity is only 1/4 to 1/6 of carbon steel. Therefore, high manganese steel castings are prone to large thermal stresses due to significant temperature differences between different parts of the casting during solidification and heat treatment cooling processes, leading to cracks, especially in complex high manganese steel castings with a thickness greater than 120 mm.

Scholars at home and abroad have conducted extensive research on the work hardening mechanism, heat treatment processes, and casting processes of high manganese steel. However, there is limited research on micro-cracks in thick and complex high manganese steel front guide wheel castings. These castings are critical components in excavator shovel products for mining, with stringent requirements for surface quality, dimensional accuracy, and internal quality. Yet, their complex structure and significant wall thickness variations, with a maximum wall thickness of 142 mm, pose challenges.

2. Experimental Materials and Methods

2.1 Experimental Materials

The experimental material was a finished ZGMn13 high manganese steel casting for mining machinery, produced from raw materials such as pig iron, manganese iron, and alloy steel. The molten steel was refined via an electric furnace followed by vacuum degassing (VD) to strictly control the oxygen content and oxidation tendency of alloy elements. Chemical analysis was conducted on samples taken from accompanying test blocks, and the chemical composition is presented in Table 1, which falls within the specified range of the national standard GB/T 5680-1998 “High Manganese Steel Castings.”

Table 1. Chemical Composition of ZGMn13 Casting (Mass Fraction, %)

| Element | ZGMn13 | GB/T 5680-1998 Range |

|---|---|---|

| C | 0.98 | 0.90–1.30 |

| Si | 0.59 | 0.30–0.80 |

| Mn | 13.42 | 11.0–14.0 |

| P | 0.036 | ≤0.040 |

| S | 0.005 | ≤0.070 |

| Mo | 0.92 | – |

| Fe | Balance | Balance |

2.2 Experimental Methods

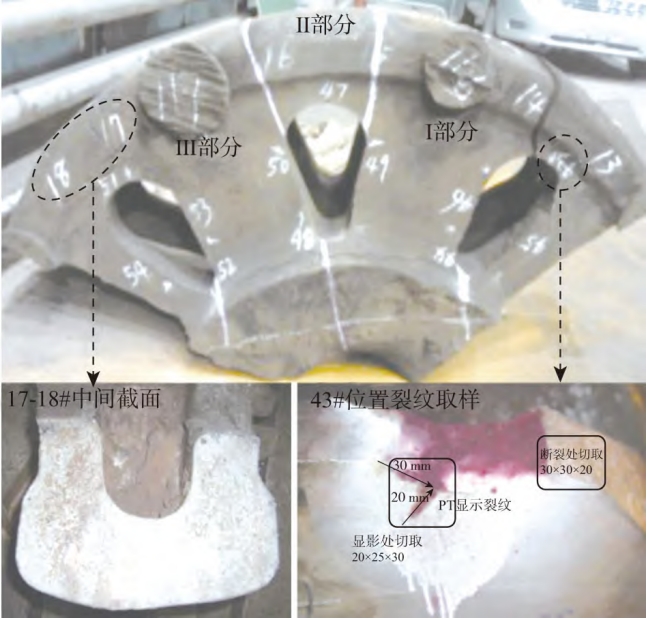

To obtain samples containing complete micro-cracks, the accurate position and direction of micro-cracks on the casting surface were identified using a PT dye test. Subsequently, samples containing cracks of 20 mm × 25 mm × 20 mm in size were cut from appropriate locations, and larger samples of 30 mm × 30 mm × 20 mm were cut from areas where the cracks were completely split. The surfaces of the cracked samples were mechanically ground and polished, then chemically etched with a 4% nitric acid-alcohol solution for approximately 6 seconds. Optical microscopes and NovaNano SEM450 field emission scanning electron microscopes were used for tissue and crack observation. Energy dispersive spectroscopy (EDS) analysis was conducted on the inclusions near the cracks and the steel matrix to determine their chemical composition.

3. Results and Analysis

High manganese steel has a relatively high linear contraction value. When the contraction of high manganese steel is obstructed, significant internal stresses are generated. The thermal conductivity of high manganese steel is low, resulting in large temperature differences between different parts of thick and complex castings during cooling or heating processes, which leads to the formation of large thermal stresses within the casting. During crystallization, high manganese steel castings are prone to forming coarse grains and columnar grains. Brittle carbides and non-metallic inclusions present at grain boundaries weaken the bonding force of the matrix and embrittle the casting. These factors determine that if there are many inclusions, carbides, and phosphorus eutectics present at grain boundaries, they will weaken the strength of the grain boundaries and may become crack sources under thermal stress [5].

The crack morphology and distribution expansion in the steel used in this experiment. The cracks in the casting are widely distributed, appearing as linear or reticulated patterns along grain boundaries under low-magnification microscopes, with most of them interconnected. Numerous carbides and inclusions of varying morphologies are present near and within the crack propagation paths.

4. Discussion on Crack Formation Mechanisms

4.1 Tensile Stress During Solidification

During the solidification process of high manganese steel castings, as the molten steel cools and solidifies, the liquid-solid interface moves inward, causing volume contraction. Due to the large wall thickness and complex structure of the casting, it is difficult for the internal stress generated during solidification to be fully released, leading to the accumulation of tensile stress. When the tensile stress exceeds the strength limit of the casting material, cracks will initiate and propagate.

4.2 Influence of Inclusions and Carbides

The presence of inclusions and carbides in high manganese steel castings has a significant impact on their mechanical properties. These inclusions and carbides, especially those distributed along grain boundaries, weaken the bonding force between grains, reducing the overall strength and toughness of the casting. When subjected to tensile stress during solidification, these weakened areas are prone to crack initiation and propagation.

4.3 Role of Phosphorus Eutectics

Phosphorus eutectics in high manganese steel castings are low-melting-point phases that are prone to segregation during solidification. Their presence increases the risk of hot cracking during solidification. When phosphorus eutectics are enriched at grain boundaries, they weaken the bonding force between grains, making the casting more susceptible to cracking.

5. Suggestions for Improvement

5.1 Optimization of Casting Process

To reduce the risk of cracking in thick and complex high manganese steel castings, the casting process should be optimized. This includes controlling the pouring temperature and pouring speed, improving the mold filling ability, and ensuring uniform cooling of the casting.

5.2 Heat Treatment Improvement

Proper heat treatment can effectively improve the mechanical properties of high manganese steel castings and reduce the risk of cracking. The heat treatment process should be designed to minimize thermal stresses and promote the uniform distribution of alloy elements within the casting.

5.3 Alloying Element Adjustment

Adjusting the alloying elements in high manganese steel can improve its crack resistance. By adding appropriate alloying elements, the segregation tendency of phosphorus and other harmful elements can be reduced, and the overall strength and toughness of the casting can be improved.

6. Conclusion

The formation of micro-cracks in thick and complex high manganese steel castings is mainly due to tensile stress during solidification and the presence of inclusions, carbides, and phosphorus eutectics. To improve the crack resistance of these castings, optimization of the casting process, improvement of heat treatment, and adjustment of alloying elements are suggested. These measures can effectively reduce the risk of cracking and improve the quality and service life of high manganese steel castings.