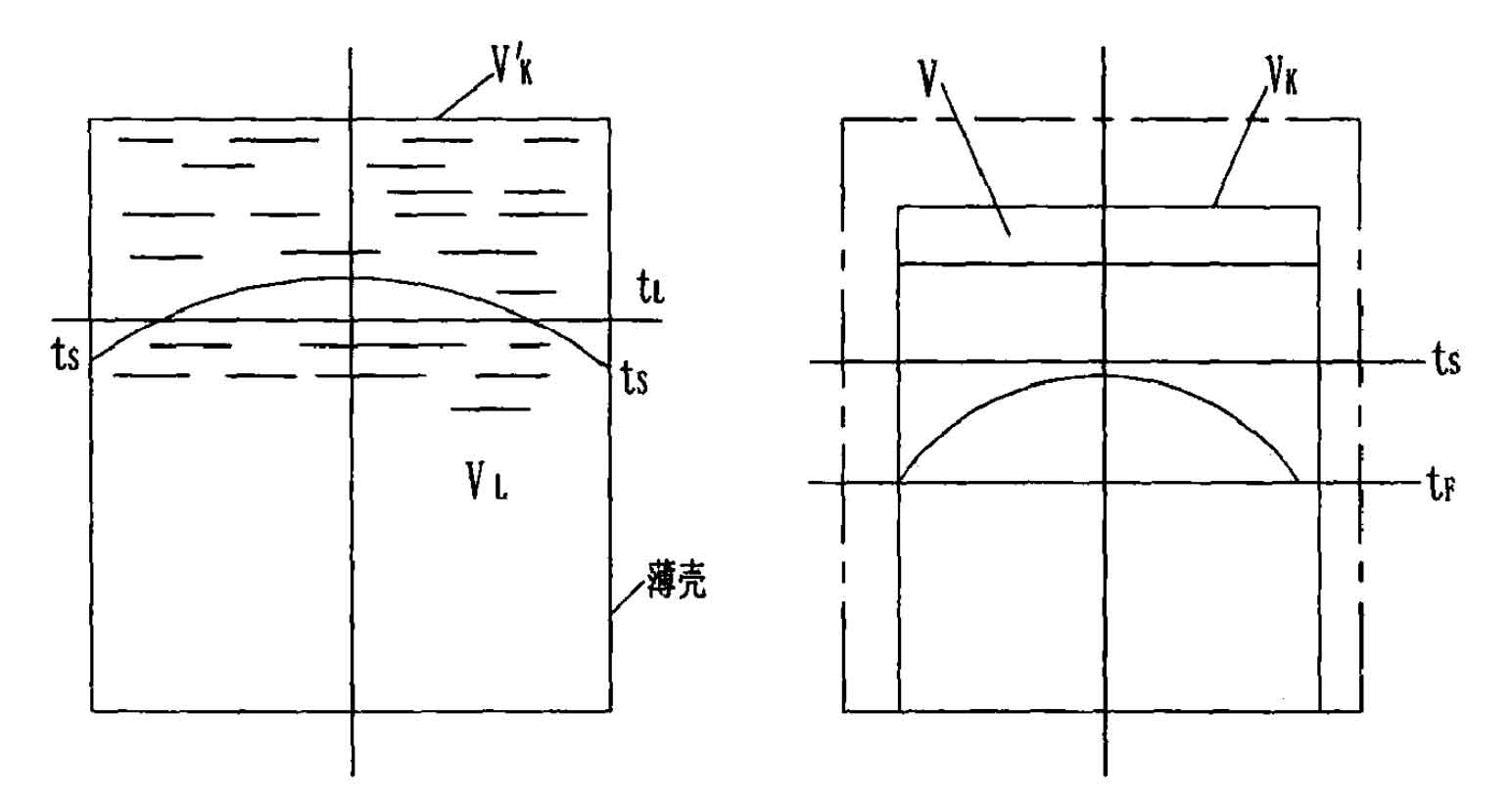

The basic cause of concentrated shrinkage defects in castings is that the liquid shrinkage and solidification shrinkage of the alloy are greater than the solid shrinkage. The basic condition for the occurrence of concentrated shrinkage defects is that the casting solidifies layer by layer from the surface to the inside, and the shrinkage defects are concentrated in the last solidified part. The volume of shrinkage defect V is equal to the volume VK of the formed thin shell cooled to a certain temperature TF, minus the volume vs of the surface of the dense solid metal formed by the liquid metal tightly surrounded by the thin shell cooled to the same temperature TF (see Figure), that is:

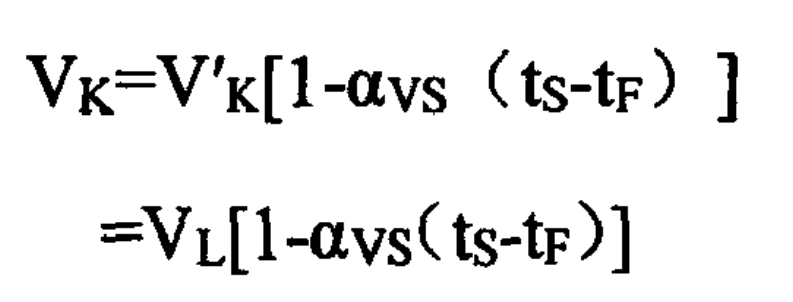

When the solidification temperature TS drops to TF, the volume VK of the thin shell shrinks due to the solid body:

Where:

V’k – volume of thin shell at ts;

VL – the volume of liquid metal surrounded by the thin shell at ts, which is approximately equal to the volume of liquid metal in the cavity;

α Vs – solid shrinkage coefficient of metal.

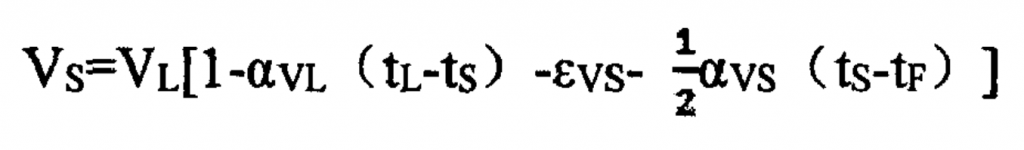

The volume of dense solid metal is:

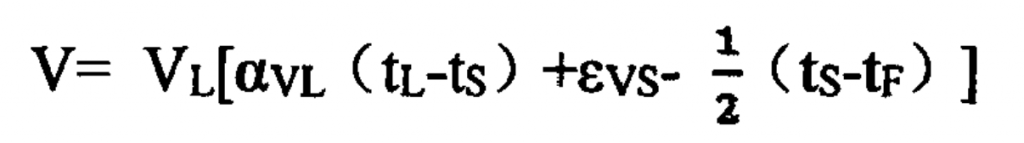

The volume V of shrinkage defects in castings is:

Where α VL – liquid shrinkage coefficient of metal.