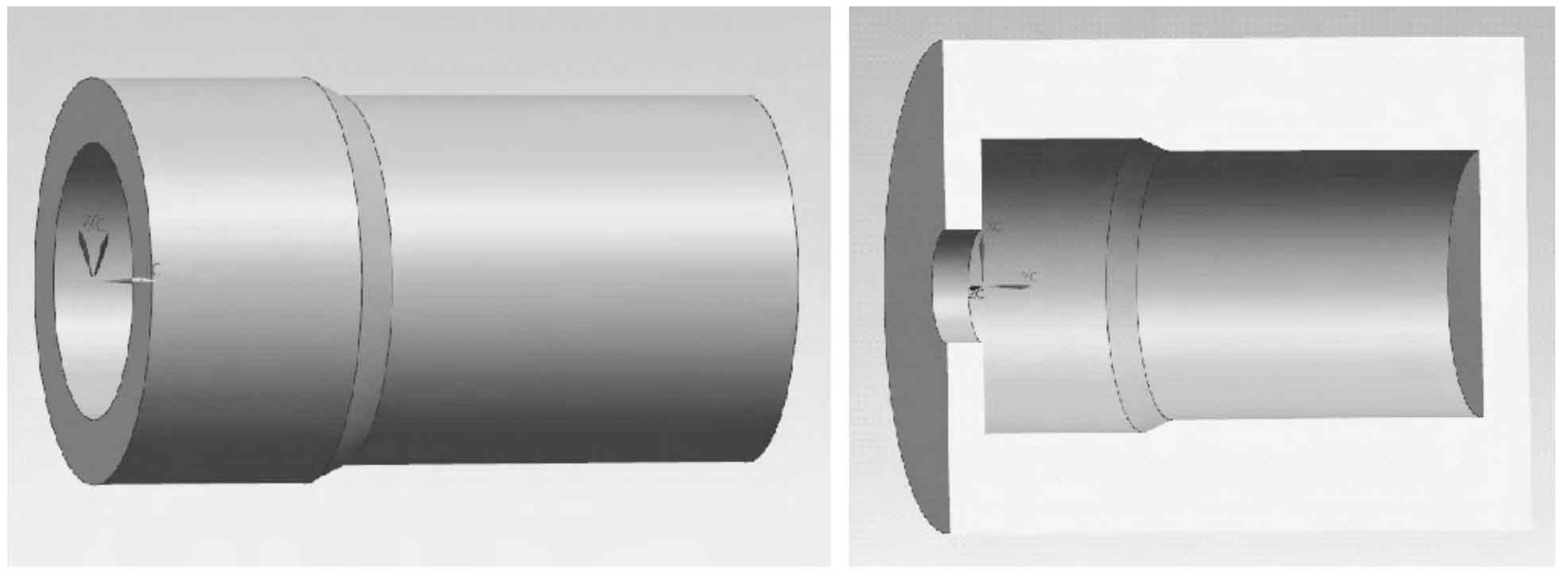

Engine is the power source of automobile and ship, and cylinder liner is one of the core components of engine. The cylinder liner is embedded in the cylinder barrel of the cylinder block, the inner hole has a piston for reciprocating motion, and the cylinder head is pressed on its upper part. The three together form the closed combustion chamber of the engine to provide power for the engine. The super large cylinder liner is used for high-power diesel engines with a cylinder diameter of φ The cylinder liner with complex structure with a maximum wall thickness of 150mm and more than 270mm is mainly used for medium speed rotating pistons such as ships.

For super large cylinder liners, cast iron is the most widely used material in actual production at present. It has good comprehensive mechanical properties, good strength, stiffness and wear resistance, and can maintain good mechanical properties at high temperature. The main methods to improve the mechanical properties of cast iron are:

① Adding elements that can promote the formation of hard phases to improve the wear resistance of castings, or adding nano phases that can improve the lubricity of castings, such as lead sulfide; Zhang Yong et al. Added B and P elements to cast iron to promote the formation of carbide with good wear resistance;

② Add elements that can refine grains and graphite, such as Mo element. Mo can change the precipitation and growth environment of ferrite to strengthen it, improve the high-temperature mechanical properties of cast iron, and significantly improve the wear resistance, creep resistance and oxidation resistance of cast iron. This kind of cast iron is also called antifriction cast iron;

③ The chemical heat treatment of the inner surface of the casting by ion co infiltration can greatly improve the wear resistance of the inner surface of the casting after treatment.

In addition, the centrifugal casting process of cylinder liner can also be optimized. With the help of computer simulation software, the filling and solidification of liquid metal can be understood faster and more economically, and the possible location of defects can be predicted. Researchers used ProCAST software to simulate the filling and solidification processes using various casting methods. Xiao Lianghong and others simulated the casting process of ZL107 aluminum alloy. The results showed that shrinkage cavity, shrinkage porosity and other defects would occur after the casting was formed, and the process plan was optimized through orthogonal test. Bazhenovve and others used ceramics as a mold to simulate the investment casting process of alloys based on titanium aluminum compounds. Liu Tiejun calculated the temperature field, flow field and pressure field of complex thin-walled parts cast by vertical centrifugal casting of titanium alloy melt. Sui Yanwei studied the formation and evolution mechanism of shrinkage cavity and porosity in the process of centrifugal casting titanium alloy castings. The results provide a reference for the numerical simulation of centrifugal casting of super large cylinder liners.

(1) In the process of centrifugal casting high molybdenum cast iron cylinder liner, the molten metal begins to fill axially at the gate position, and then rotates against the inner wall of the mold, and the rotation direction is consistent with the direction of the mold. After entering the mold, the molten metal is continuously filled forward in the form of laminar flow. The filling sequence is that the molten metal first fills the left mold cavity, and the molten metal layer continues to thicken and spread to the right until the mold cavity is filled. The sharing time is 90.3s.

(2) During centrifugal casting of high molybdenum cast iron cylinder liner, the temperature of molten metal at the far end is about 100 ℃ lower than that at the near end. The temperature at both ends of the axial direction of the casting is low, the middle temperature is high, and the temperature of the outer surface is always lower than that of the inner surface. The temperature of molten metal near the inlet is higher than that far away from the inlet, and the cooling speed is first fast and then slow. Due to the release of crystallization latent heat, a temperature platform will appear. At the last solidification position of molten metal, shrinkage cavity and porosity are easy to appear. The solidification sequence of the casting is from outside to inside, and the final solidification position is in the middle of the thick wall end of the casting.

(3) In the process of centrifugal casting high molybdenum cast iron cylinder liner, the pressure field is basically concentric when the molten metal just fills the mold, and the pressure is directly related to the diameter of the inner hole of the mold, the wall thickness of the casting and the centrifugal speed. The maximum pressure of molten metal is 0.5063mpa, and the feeding capacity of molten metal is strong; Due to the different radius and wall thickness of the casting, the maximum pressure difference between the outer surface and the inner surface is 0.317mpa, and the pressure difference between the wall thickness and the thin wall of the casting is 0.097mpa. Due to the influence of gravity, the pressure difference between the lower part and the upper part of the casting is 0.023mpa.

(4) According to the simulation results of temperature field, flow field and pressure field φ 400mm and φ The process parameters of 580mm super large cylinder liner in the actual production process were optimized, and the castings produced had complete mold filling and good forming quality, which verified the accuracy of the simulation results.

The horizontal centrifugal casting process of super large high molybdenum cast iron cylinder liner is designed by using ProCAST software. The three-dimensional model of the casting is divided into finite element meshes, and the initial conditions and boundary conditions in the casting process are set. At the same time, the rotation parameters, reasonable pouring time and pouring position are set. The coupling calculation of temperature field, flow field and pressure field in the horizontal centrifugal casting process of the cylinder liner is carried out, The purpose is to provide reference for its production and application.