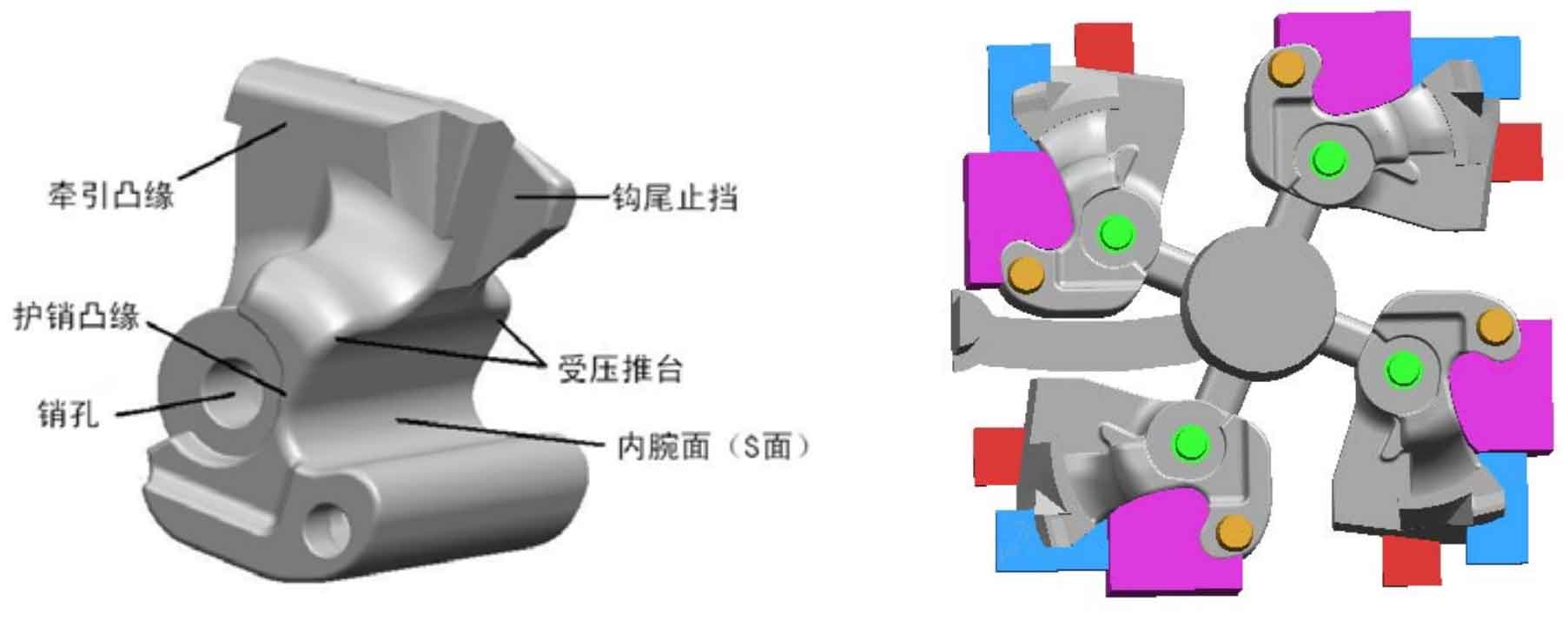

Type 16 coupler knuckle is a complex small steel casting. The overall size of the steel casting of coupler knuckle is 280 × two hundred and ninety-seven × 220mm, with a single piece weight of 40kg. The structure of the coupler tongue steel casting is shown in figure (a). The coupler tongue is connected with the hook body through the coupler tongue pin. The surface of the coupler tongue is mostly smooth, the structure is complex, there is a cavity in it, and the wall thickness is uneven. The minimum wall thickness is 14mm and the maximum wall thickness is 65mm.

The main failure forms of coupler knuckle are fracture and wear. The root causes of both are the existence of casting defects such as air hole, slag inclusion and sand sticking, shrinkage cavity and porosity, micro crack and so on. The cracks on the knuckle mainly exist at the upper and lower corners of the inner side of the knuckle, the back of the knuckle and the pin hole. The upper and lower corners of the inner side of the coupler knuckle, that is, the end of the coupler knuckle working face itself, bear great stress concentration. The casting defect of the coupler knuckle steel casting destroys the material continuity, reduces the material strength and plasticity, and forms a stress concentration at the front of the defect. The superposition of the two is very easy to produce cracks, and the wear debris generated by the crack damage will accelerate the wear of the above parts.

The original process of steel castings for coupler knuckle adopts a box of eight pieces and a group of four pieces, with flat pouring. A side concealed riser is set at the center of each group to ensure mold filling and solidification feeding. The process yield is 66.1%. The sand core is triethylamine resin sand core (5 sand cores with color). Its process diagram is shown in figure (b). In order to simplify the simulation calculation, the model adopts 1 / 2 mirror symmetrical model.