Comparative Analysis of Cast Irons

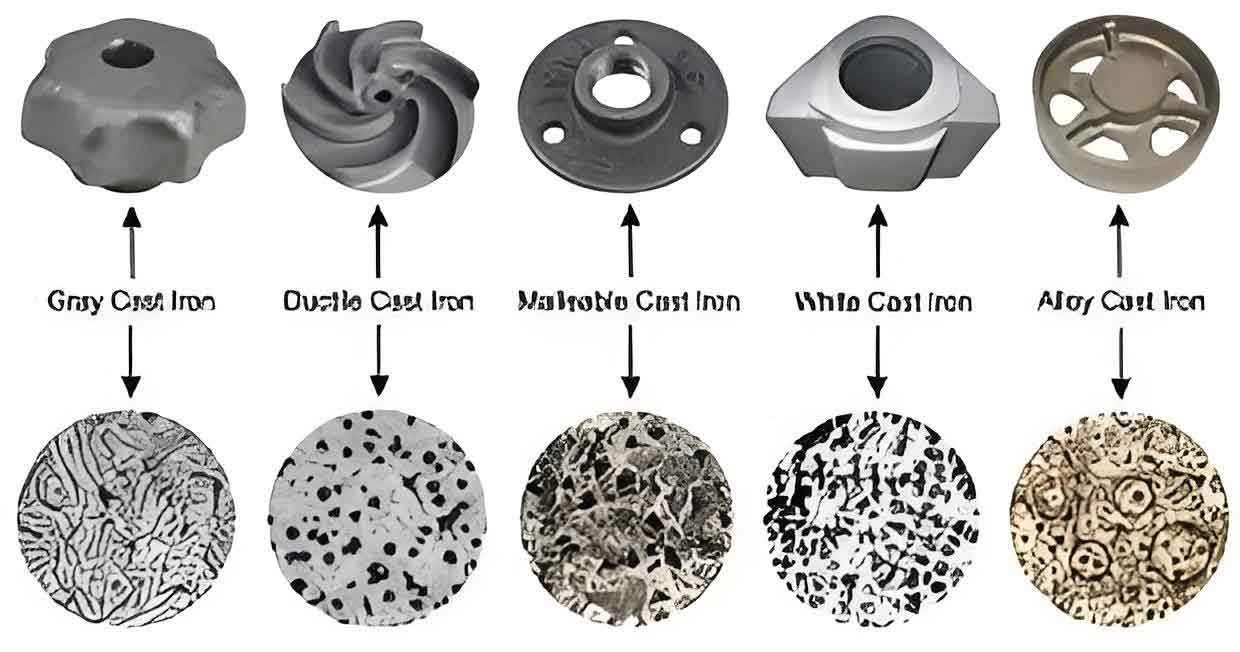

Cast irons are a group of iron-carbon alloys with a carbon content greater than 2%. The main types of cast iron include gray, white, ductile, and malleable cast irons. Each type has distinct properties and applications.

1. Gray Cast Iron

- Composition: Contains carbon in the form of graphite flakes.

- Mechanical Properties:

- Tensile Strength: 200-400 MPa

- Compressive Strength: High, due to the presence of graphite flakes.

- Hardness: 150-250 HB

- Damping Capacity: Excellent, absorbs vibrations well.

- Brittleness: High, due to the flake graphite structure.

- Applications: Engine blocks, pipes, machine tool frames, and cookware.

2. White Cast Iron

- Composition: Contains carbon in the form of cementite (iron carbide).

- Mechanical Properties:

- Tensile Strength: 200-350 MPa

- Compressive Strength: High, due to cementite structure.

- Hardness: 400-600 HB (very hard)

- Wear Resistance: Excellent, but very brittle.

- Brittleness: Very high, practically no ductility.

- Applications: Abrasion-resistant surfaces, mill liners, and crushing equipment.

3. Ductile Cast Iron (Nodular or Spheroidal Graphite Iron)

- Composition: Contains nodules of graphite instead of flakes.

- Mechanical Properties:

- Tensile Strength: 400-700 MPa

- Compressive Strength: High.

- Hardness: 180-300 HB

- Ductility: Good, elongation up to 18%.

- Impact Resistance: Good, due to nodular graphite structure.

- Applications: Automotive components (crankshafts, gears), pipe fittings, and pressure vessels.

4. Malleable Cast Iron

- Composition: Contains temper carbon in the form of clusters or nodules.

- Mechanical Properties:

- Tensile Strength: 350-550 MPa

- Compressive Strength: High.

- Hardness: 130-250 HB

- Ductility: Good, elongation up to 10%.

- Impact Resistance: Good.

- Applications: Railroad equipment, farm machinery, and electrical fittings.

Comparative Summary

| Property | Gray Cast Iron | White Cast Iron | Ductile Cast Iron | Malleable Cast Iron |

|---|---|---|---|---|

| Graphite Form | Flakes | Cementite | Nodules | Temper Carbon |

| Tensile Strength | 200-400 MPa | 200-350 MPa | 400-700 MPa | 350-550 MPa |

| Hardness | 150-250 HB | 400-600 HB | 180-300 HB | 130-250 HB |

| Ductility | Low | Very Low | High | Moderate |

| Wear Resistance | Moderate | High | Moderate | Moderate |

| Brittleness | High | Very High | Low | Low |

| Applications | Engine blocks, pipes | Abrasion-resistant | Automotive components | Railroad equipment |

| Machine tool frames | surfaces, mill liners | Pipe fittings, gears | Farm machinery | |

| Cookware | Crushing equipment | Pressure vessels | Electrical fittings |

Applications and Mechanical Properties Analysis

- Gray Cast Iron is widely used where high vibration damping and compressive strength are needed, such as in engine blocks and machine tool frames. However, its brittleness limits its use in high-tensile applications.

- White Cast Iron is best for applications requiring high wear resistance and hardness, but its brittleness confines it to non-structural components subjected to abrasive wear.

- Ductile Cast Iron combines good tensile strength and ductility, making it ideal for automotive and heavy machinery parts that require strength and impact resistance.

- Malleable Cast Iron is versatile and used in applications needing good tensile strength and ductility, especially where parts must withstand impact and wear.

Each type of cast iron has unique properties that make it suitable for specific applications, balancing the trade-offs between strength, hardness, ductility, and wear resistance.