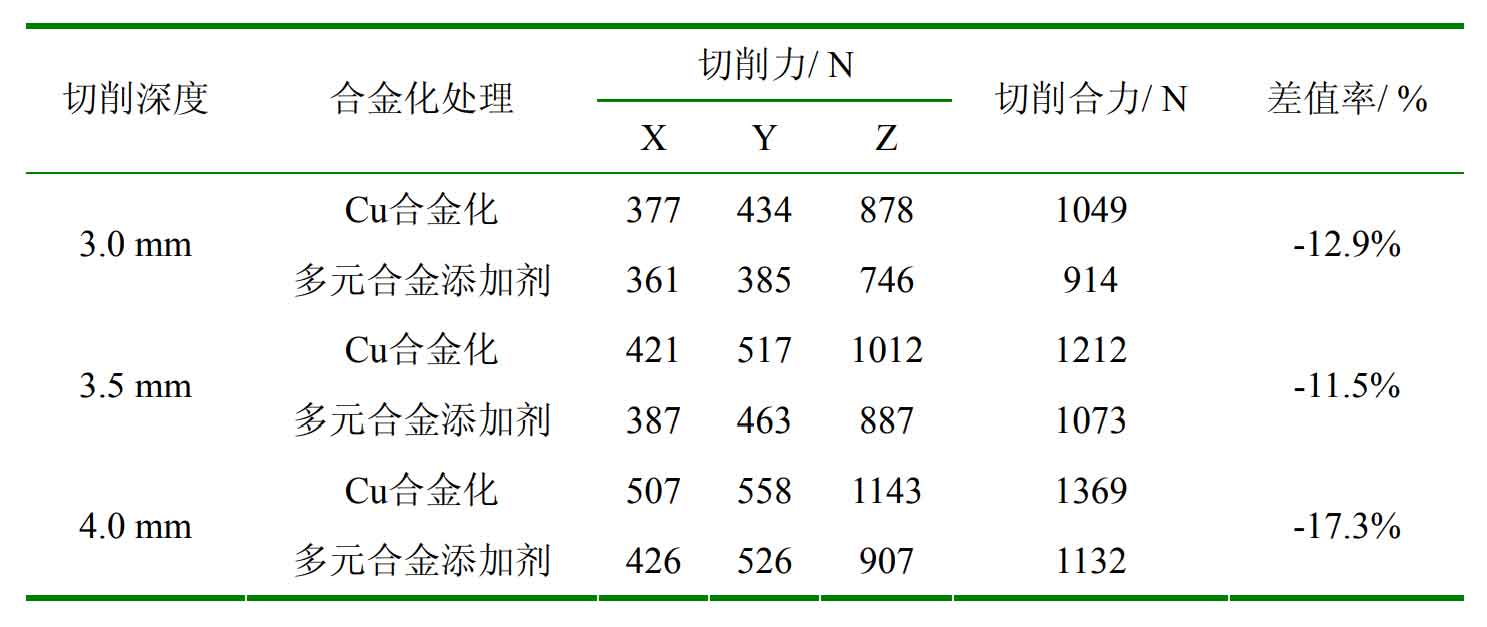

In the process of gray cast iron cutting experiment, the measurement cycle is 20 s, the cutting length of the blade is very small, and the impact on the wear of the tool can be ignored. Therefore, the experiments use the installation of the same tool to complete the cutting force experiment with the same processing parameters. In the process of gray cast iron cutting, the tool is not changed or reinstalled, so as to avoid the impact of the change of tool reinstallation angle on the cutting force in the same group of processing experiments. Cutting depth: 3.0, 3.5, 4.0 mm. The change of cutting force of gray cast iron test sample is shown in the table.

It can be seen from the table that the cutting resistance of the turning tool in three directions is greater than that of the gray cast iron sample alloyed with multi-element alloy additives when cutting the gray cast iron sample alloyed with copper at three cutting depths. Compared with copper alloying, the cutting force is reduced by 12.9%, 11.5% and 17.3% respectively. Therefore, the cutting performance of gray iron castings alloyed with multi alloy additives is better than that of gray iron castings alloyed with copper.