The multi-element alloy additive is designed according to the research results at home and abroad on the influence of Alloying on the mechanical properties and processability of gray cast iron, combined with the application experience of China Yituo. The raw materials used are: high carbon ferrochromium containing 68% chromium, medium carbon ferromanganese containing 80% manganese and No. 1 rare earth alloy containing 25% rare earth. Multicomponent alloy additive is obtained by melting in medium frequency induction furnace. Its actual composition is: 38.70% Cr, 13.50% Si, 8.50% Mn, 5.30% RE, and the rest is Fe. Finally, the prepared multi-element alloy additive alloy block is broken into 0.5-2.0 mm particles for use.

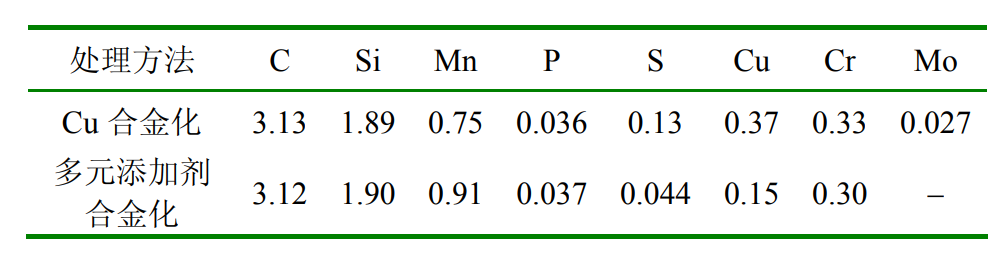

HT300 samples were prepared by alloying with multicomponent alloy additives and alloying element copper. The composition of molten iron after treatment is measured by direct reading spectrum analyzer, as shown in Table 1.

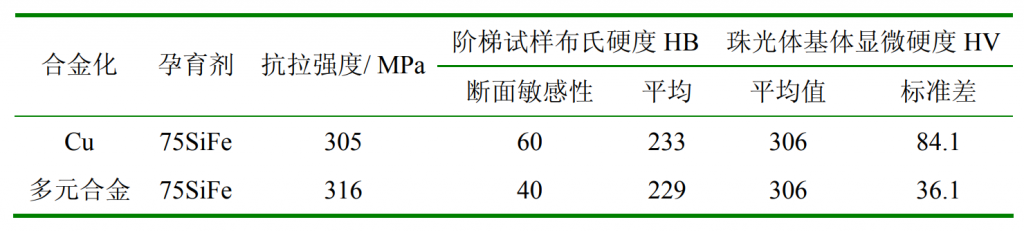

The mechanical properties of gray cast iron samples with different alloying treatments are shown in Table 2. It can be seen from table 2 that the tensile strength of gray cast iron alloyed with multi-element alloy additives is basically the same as that of gray cast iron alloyed with copper, both of which meet the requirements of HT300. The Brinell hardness and microhardness of gray cast iron alloyed with multi alloying additives are basically equal to those of copper alloyed samples. The mechanical properties of multicomponent alloy additive alloying meet the requirements of replacing copper alloying.

From table 2, the section sensitivity of Cu alloyed samples can be obtained Δ Hb is 60 Hb. Section sensitivity of multicomponent alloy additive samples Δ Hb is 40 Hb. The hardness of gray cast iron treated with multi alloy additives is less affected by the change of wall thickness, and the section sensitivity of its alloyed sample is better than that of copper alloyed sample. The microhardness of pearlite matrix of samples with different alloying treatments is equal. From the standard deviation of indentation, it can be seen that the Microindentation diameter of copper alloyed sample fluctuates widely and the microhardness of matrix is uneven. The microhardness fluctuation range of the samples treated with multi-element alloy additives is small, and the microhardness uniformity of gray cast iron is better than that of copper alloying.