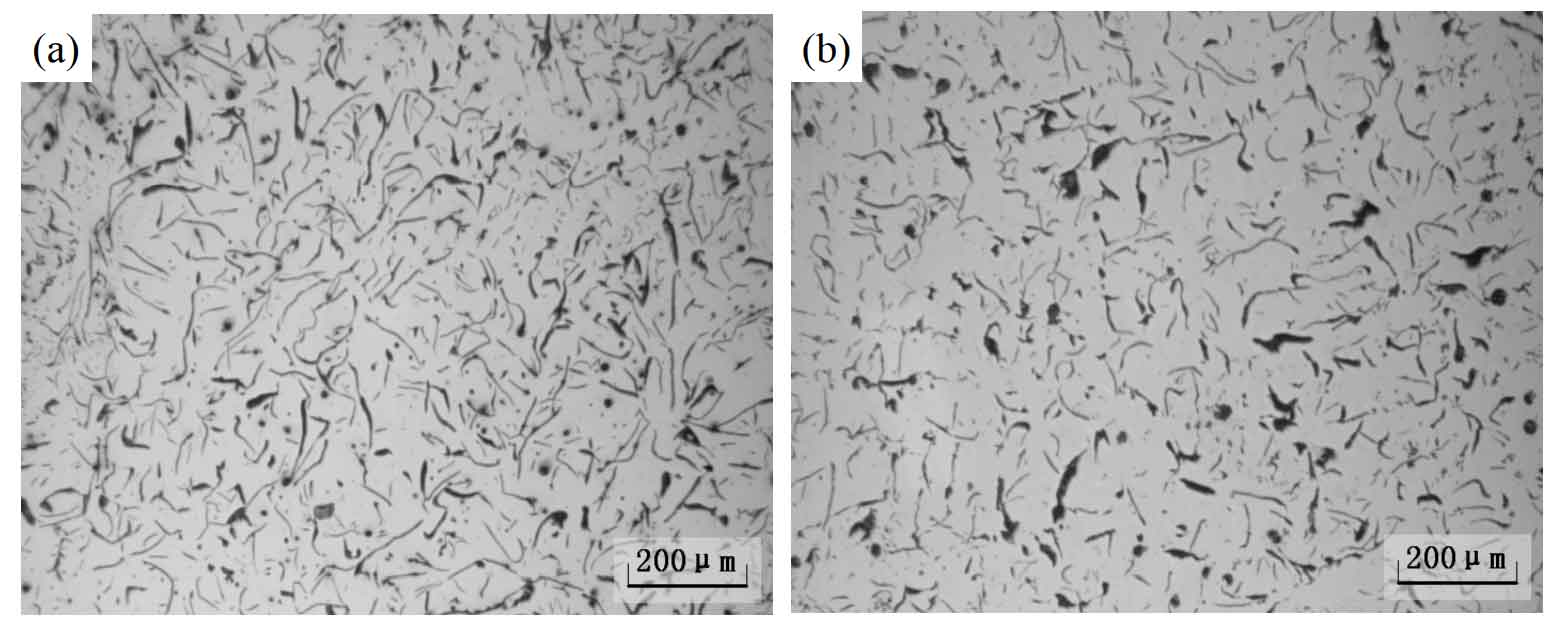

The graphite morphology of the two gray cast iron samples is shown in Figure 1. It can be seen from Figure 1 that the graphite morphology of the two kinds of alloyed gray cast iron is mainly fine, curved and evenly distributed type a graphite. In Fig. 1 (b), the copper alloyed gray cast iron sample has type a graphite mixed with massive type C graphite. Compared with A-type graphite, C-type graphite is not conducive to tool lubrication and chip breaking, which increases the cutting force and leads to poor machining performance. The graphite contents of the two alloyed samples with different treatments were 21.55% and 20.42% respectively. In the same volume, because the graphite is small, the number of graphite is relatively large and the graphite spacing is small, when the gray cast iron is cut by the high-speed rotating tool, the plastic deformation of the material in the local area is relatively small, which is easy to form banded chips with small bending degree, reduce the friction force and wear area of the tool and weaken the phenomenon of “tool burning”, So as to improve the cutting performance.

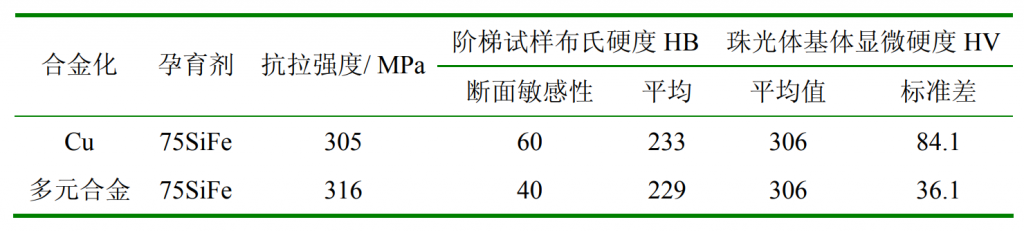

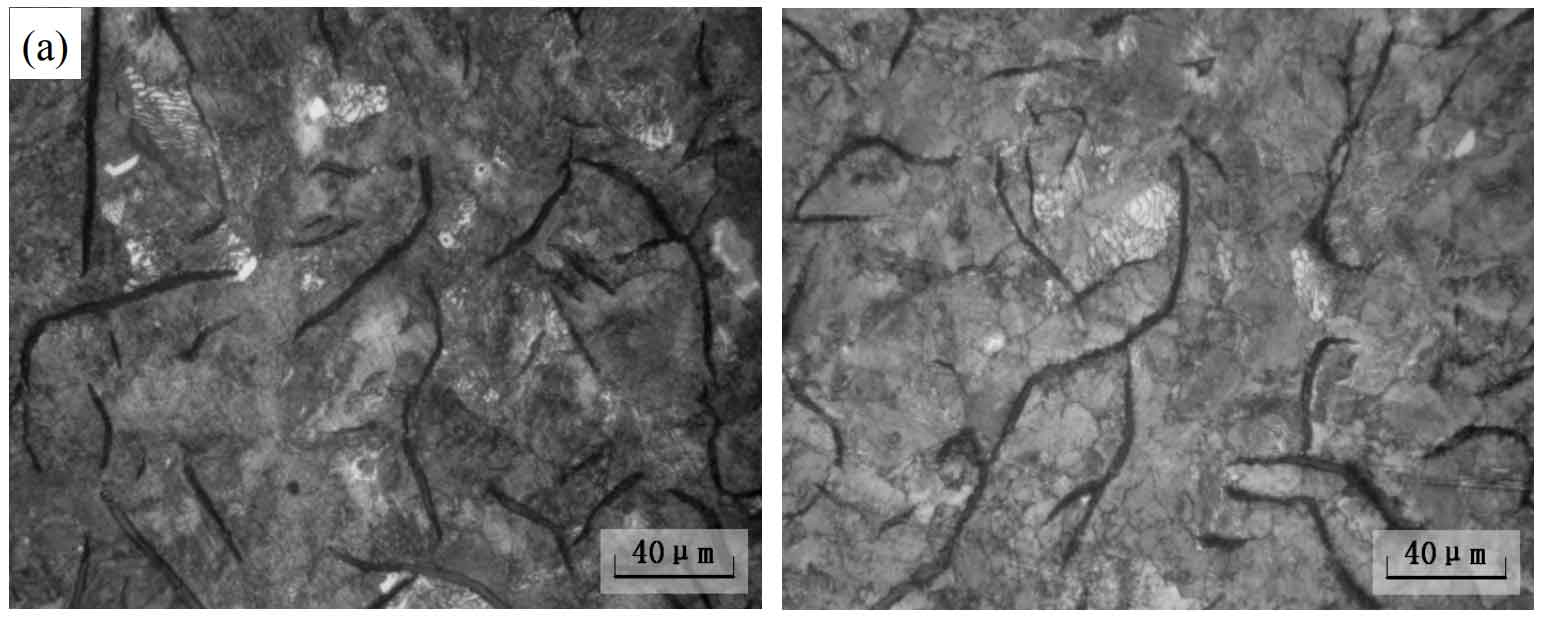

Fig. 2 is a picture of the matrix structure of different alloyed gray cast iron. It can be seen that the gray cast iron treated by multicomponent addition and copper alloying is pearlite matrix. Combined with the microhardness of pearlite matrix in the table, it can be concluded that the microstructure of gray cast iron alloyed with multi-element alloy additives is more uniform than that of gray cast iron alloyed with copper. There are many factors affecting the machinability of gray cast iron, one of which is the heterogeneity of materials. It is mainly manifested in the non-uniformity of structure and hardness. When there are a certain number of hard inclusions in pearlite matrix, its uniformity is poor. The fluctuation of pearlite hardness causes the fluctuation of shear deformation resistance, which reduces the machinability of the material.