Machinability refers to the ease with which a material can be cut, shaped, or finished using various machining processes. The machinability of cast irons varies significantly among gray, white, and ductile types due to differences in their microstructure and mechanical properties.

1. Gray Cast Iron

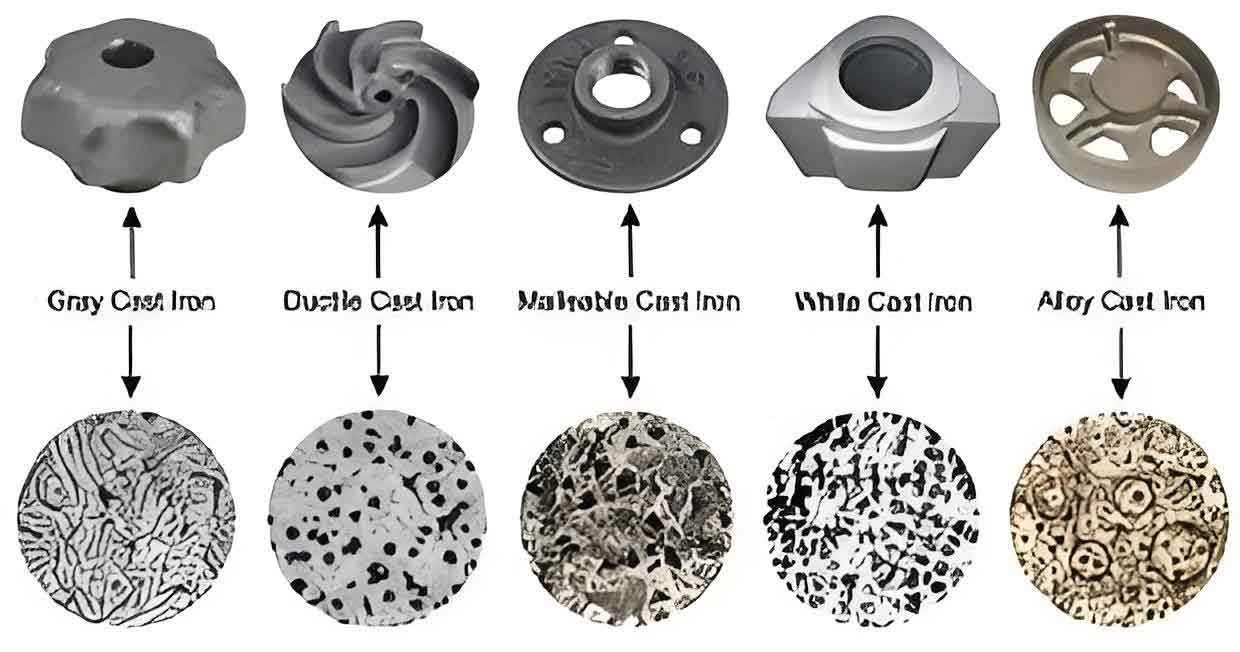

- Microstructure: Contains graphite flakes dispersed in a matrix of ferrite, pearlite, or a combination of both.

- Machinability Characteristics:

- Ease of Machining: Excellent machinability due to the presence of graphite flakes, which act as chip breakers and lubricants.

- Tool Wear: Minimal tool wear because the graphite provides lubrication, reducing friction.

- Surface Finish: Good surface finish can be achieved with minimal effort.

- Cutting Speed: Higher cutting speeds can be used compared to other cast irons.

- Heat Dissipation: Graphite flakes help dissipate heat, reducing the risk of thermal damage.

- Applications: Engine blocks, cylinder heads, machine tool frames, cookware.

2. White Cast Iron

- Microstructure: Contains hard, brittle cementite (iron carbide) with little or no free graphite.

- Machinability Characteristics:

- Ease of Machining: Poor machinability due to the presence of hard cementite, which makes cutting difficult.

- Tool Wear: High tool wear rates because cementite is abrasive and hard.

- Surface Finish: Achieving a good surface finish is challenging and requires specialized cutting tools.

- Cutting Speed: Lower cutting speeds are necessary to reduce tool wear and avoid excessive heat generation.

- Heat Dissipation: Poor heat dissipation due to the lack of graphite, leading to increased risk of thermal damage.

- Applications: Abrasion-resistant surfaces, mill liners, crushing equipment.

3. Ductile Cast Iron

- Microstructure: Contains spherical graphite nodules in a matrix of ferrite, pearlite, or a combination.

- Machinability Characteristics:

- Ease of Machining: Good machinability, though not as high as gray cast iron due to the nodular graphite.

- Tool Wear: Moderate tool wear, more than gray cast iron but significantly less than white cast iron.

- Surface Finish: Good surface finish can be achieved, especially in ferritic grades.

- Cutting Speed: Higher cutting speeds can be used, particularly with ferritic ductile iron.

- Heat Dissipation: Better than white cast iron but not as effective as gray cast iron due to the nodular graphite structure.

- Applications: Automotive components (crankshafts, gears), pipe fittings, pressure vessels.

Summary of Machinability

| Property | Gray Cast Iron | White Cast Iron | Ductile Cast Iron |

|---|---|---|---|

| Ease of Machining | Excellent | Poor | Good |

| Tool Wear | Minimal | High | Moderate |

| Surface Finish | Good | Challenging | Good |

| Cutting Speed | High | Low | Moderate to High |

| Heat Dissipation | Excellent | Poor | Better than white iron |

| Applications | Engine blocks, machine frames | Abrasion-resistant surfaces | Automotive components, fittings |

Detailed Analysis

1. Gray Cast Iron Machinability

- Advantages:

- Graphite flakes make chips break easily, reducing the effort required for machining.

- The self-lubricating nature of graphite reduces the need for cutting fluids.

- Excellent thermal conductivity of graphite helps manage heat during machining.

- Disadvantages:

- Brittle nature can lead to chipping and cracking if not handled properly.

- Produces a significant amount of dust and debris, which requires good ventilation and cleanup.

2. White Cast Iron Machinability

- Advantages:

- Extremely hard and wear-resistant, ideal for parts subject to abrasion.

- Disadvantages:

- Extremely difficult to machine due to the high hardness of cementite.

- Requires specialized cutting tools (e.g., carbide or diamond-tipped) and slower machining speeds.

- High tool wear and frequent tool changes increase machining costs and time.

- Poor surface finish requires additional processing steps.

3. Ductile Cast Iron Machinability

- Advantages:

- Nodular graphite provides a good balance between strength and machinability.

- Easier to machine than white iron and almost as good as gray iron.

- Versatile applications due to the combination of strength, toughness, and ductility.

- Disadvantages:

- Slightly more challenging to machine than gray iron, especially in pearlitic grades.

- Tool wear is higher than gray iron but manageable with proper tool selection and cutting parameters.

Conclusion

The machinability of cast irons is heavily influenced by their microstructure. Gray cast iron, with its graphite flake structure, offers the best machinability, making it ideal for applications requiring extensive machining. White cast iron, while extremely hard and wear-resistant, is the most difficult to machine due to its cementite content. Ductile cast iron strikes a balance between machinability and mechanical properties, making it suitable for a wide range of industrial applications. Proper selection of cutting tools, machining parameters, and heat treatment processes can optimize the machinability of each type of cast iron.