In order to verify the nondestructive ultrasonic flaw detection test results of typical four branch cast steel joints, take four typical casting defects as examples to compare and verify the destructive nondestructive flaw detection results. The comparison process of rib looseness, riser shrinkage, upper type delamination and branch pipe shrinkage is shown in Figure 1.

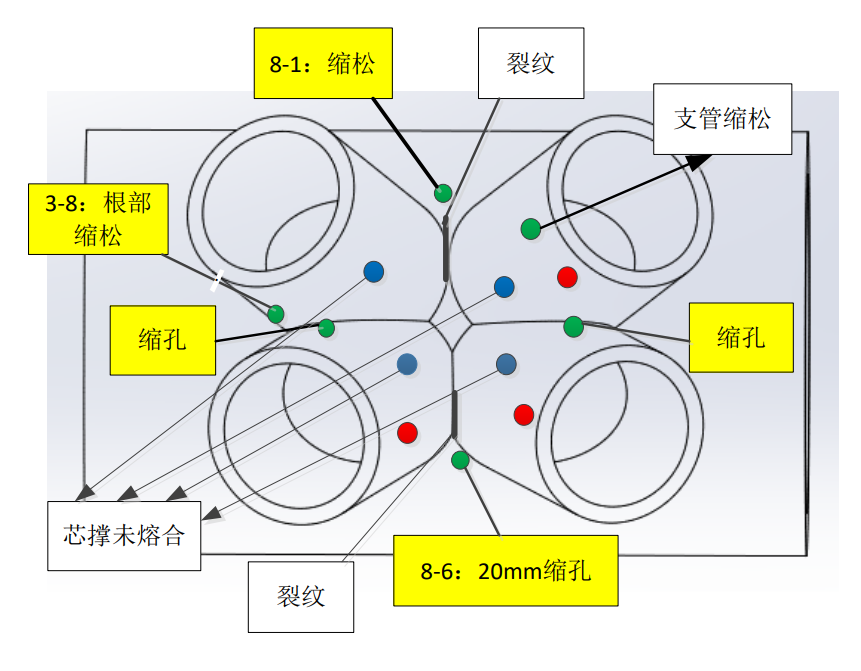

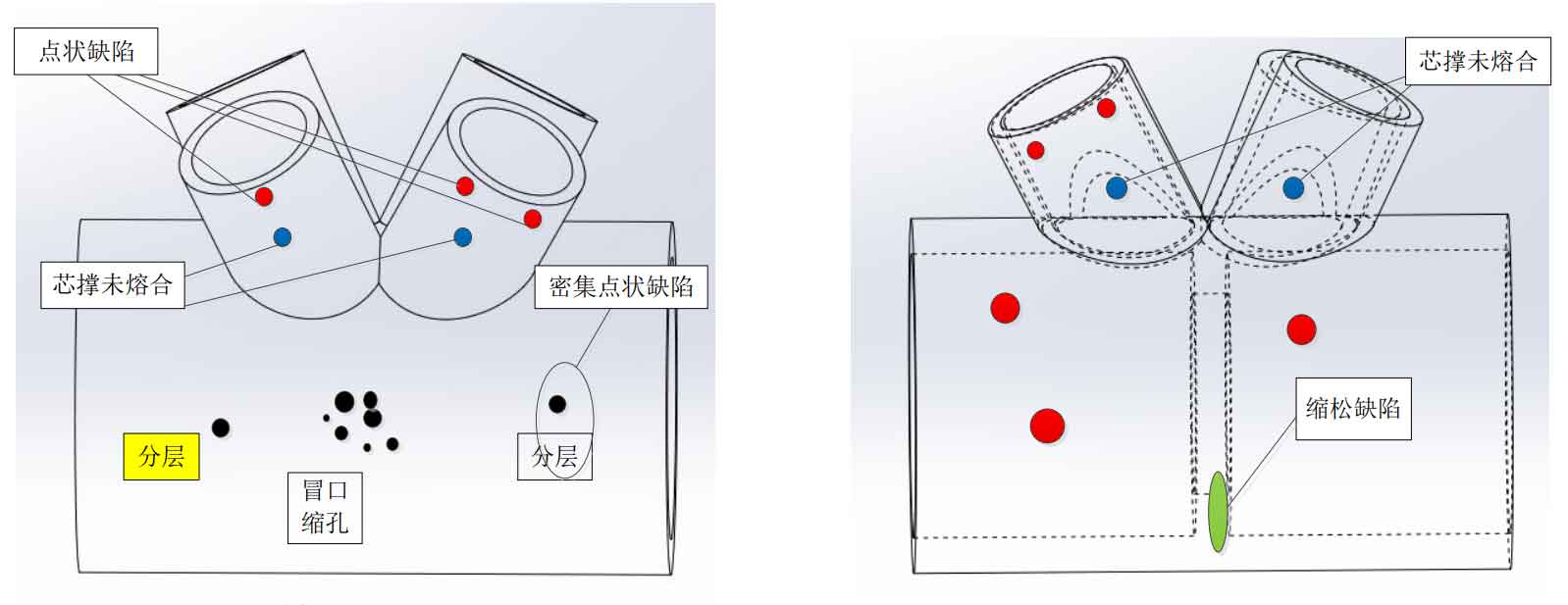

The slice inspection results of the main casting defects are shown in Figure 2. Among them, red is the dot defect, green is the shrinkage defect, blue is the non fusion defect, and yellow is the casting defect not detected by ultrasonic. There are six most serious casting defects, one is the shrinkage defect near the riser, the other is the delamination defect at the top of the cast steel joint, and the third is the shrinkage defect along the circumferential direction at the junction of the stiffener and the main pipe, Four are shrinkage defects under the intersection line of cast steel joint and branch pipe (not detected by ultrasonic), five are non fusion of core support of branch pipe, and six are cracks at the root of cast steel joint and branch pipe (magnetic particle detection). The shrinkage defects near the riser are dense, the pores are large, and the appearance is visible. The casting defects near the riser are detected by ultrasonic; There are two delamination defects at the top of the cast steel joint, which extend about 3cm along the circumferential direction, which is more serious. One delamination defect was detected by ultrasonic flaw detection, and another was missed; There are shrinkage defects along the circumferential direction of the boundary at the junction of the stiffening plate and the main pipe. The defects here are detected by ultrasonic flaw detection and their properties are accurately determined; There are large shrinkage defects at the intersection of branch pipes, which is the blind area of ultrasonic flaw detection and can not be detected at all; The casting defects of incomplete fusion of core support are generally visible visually, and repair welding will be carried out after casting; Cracks at the root of the branch pipe will also be repaired by welding.

The test results show that the ultrasonic inspection results have good reliability, but they can not accurately distinguish the nature of casting defects, nor can they detect the casting defects in the complex modeling area. The casting defects in R area, which is in the blind area of flaw detection, have not been detected.

The above test and analysis results can provide some suggestions for nondestructive testing of cast steel joints:

(1) In addition to the necessary surface magnetic particle testing, angle probe should also be used to detect the internal area of R area of cast steel joint. The slice test shows that the R area of cast steel joint is the area with frequent casting defects, and there are internal shrinkage cavity and porosity defects in addition to surface cracks. The research also shows that the casting defects in the R-zone of the cast steel joint are basically over standard casting defects, which must be removed.

(2) Ultrasonic flaw detection can not distinguish the severity of shrinkage cavity and porosity near the stiffener. The waveform shows that the bottom wave is reduced to zero, and the casting defect wave is very low, which only indicates that there are shrinkage defects, and the severity of shrinkage defects cannot be determined by equivalent method.

(3) The defects of shrinkage cavity and looseness are easy to appear near the rib plate. The stiffener and nozzle rib plate should become the focus of ultrasonic flaw detection.