The composition of nodular cast iron crankshaft obtained from ZHY Casting is shown in the table. Cinnamon sand is used for sand shell and gray cast iron is used for metal mold instead of calculation.

| Element | C | SI | Mn | Cu | Mg | P | S |

| Content (%) | 3.8 | 2.0 | 0.4 | 0.6 | 0.05 | 0.05 | 0.02 |

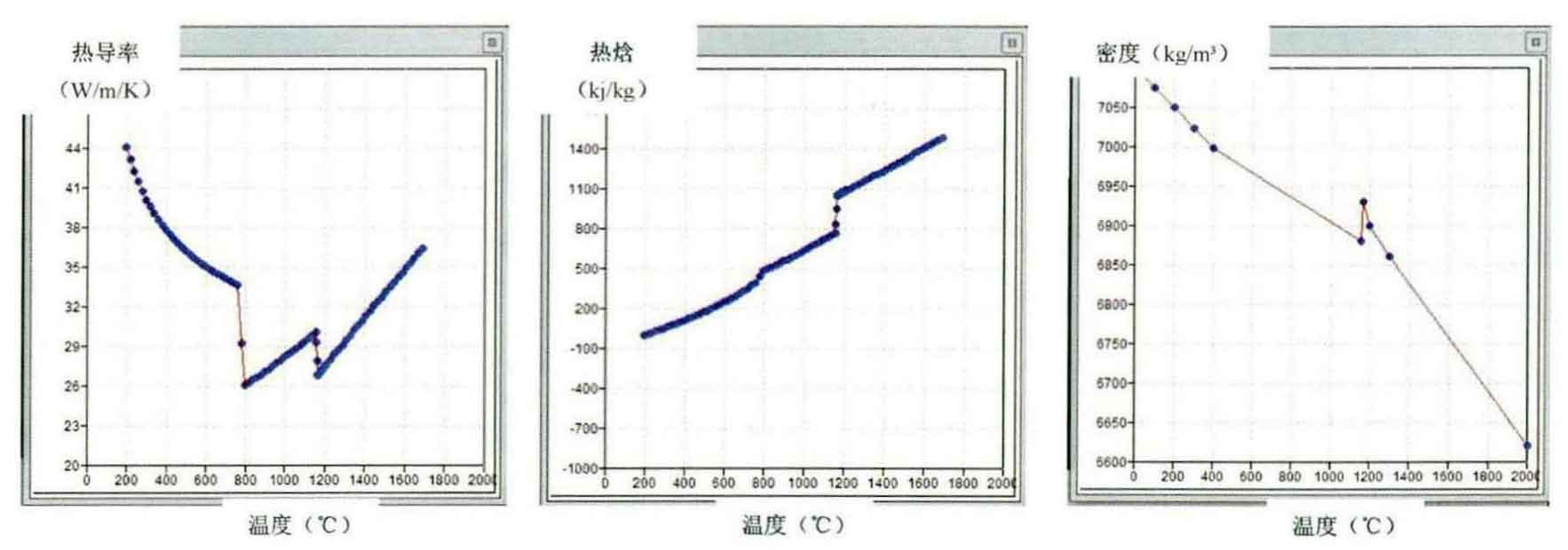

The composition of alloy elements will affect the thermophysical parameters. According to the alloy composition actually used by ZHY Casting, the main thermophysical parameters of nodular cast iron crankshaft with this composition are calculated by using JMatPro software. The liquidus and solidus temperatures are 1200 ° C and 1158 ° C respectively. The thermal conductivity, enthalpy and density curve corrected according to empirical values are shown in the figure.

Firstly, simulate and calculate the temperature field and flow field of ZHY Casting under the existing process conditions. The thickness of sand shell filled by this process is 6mm. Cold mold pouring is adopted, the sand shell temperature and iron mold temperature are 30 ° C, and the pouring temperature of molten iron is 1420 ° C. The pouring speed is calculated as 1460mm / s according to the actual head height. Cool in air. The interface between casting and sand shell, sand shell and mold is sand metal, and the empirical value is adopted for the heat transfer coefficient. It is the filling flow under the action of gravity.