Abstract: This article delves into the intricacies of the 3D printing casting process for cylinder head castings, highlighting its advantages, technical specifics, and transformative impact on traditional casting methods. Through detailed analysis and illustrative examples, the paper aims to demonstrate the potential of 3D printing in revolutionizing the casting industry.

Introduction

Cylinder heads are box-shaped components with complex internal structures, produced through casting and subsequent machining for assembly. Traditional casting methods for these components face challenges such as low yield rates, significant dimensional deviations, and design constraints imposed by conventional casting techniques. To address these issues, this paper introduces a novel 3D printing casting process for cylinder head castings, exploring its benefits and wide-ranging application prospects.

1. Overview of 3D Printing Technology

The core concept of 3D printing technology originated from photographic sculpture and landform modeling techniques in the 19th century. However, limited by material science and computer technology at the time, it did not achieve widespread commercialization until the 1980s, following formal research beginning in the 1970s. 3D printing, a form of rapid prototyping, constructs objects based on digital model files using powdered metals, plastics, or other bindable materials through layer-by-layer printing. Its technical characteristics include mold-free rapid freeform fabrication, near-net-shape to net-shape manufacturing of complex components, full digitization, and high flexibility.

2. The 3D Printing Casting Process for Cylinder Head Castings

2.1 Product Information

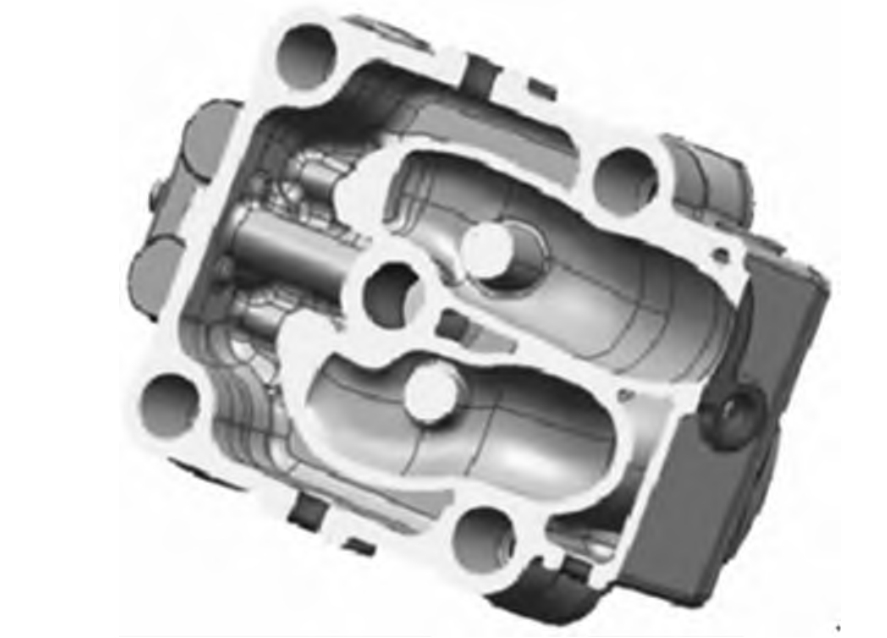

The cylinder head casting discussed in this paper measures 615 mm × 420 mm × 290 mm, with a minimum wall thickness of 8-10 mm and locally thicker sections. It is made from RuT350 material. The internal structure of the cylinder head is highly complex, as illustrated in Figures 2 and 3.

| Dimensions | 615 mm × 420 mm × 290 mm |

|---|---|

| Material | RuT350 |

| Wall Thickness | 8-10 mm (minimum) |

Figure 2: Cylinder Head Casting

(Insert image of the cylinder head casting)

Figure 3: Internal Structure of Cylinder Head

(Insert image of the internal structure)

2.2 Process Planning

Leveraging the flexibility of 3DP (Three-Dimensional Printing) technology, we designed the casting process without considering molding or core extraction requirements. Using 3D CAD software, we modeled the cylinder head and designed the casting process, establishing a 3D casting process model. Through simulation of filling patterns, we selected a top-gating system for its smooth filling, effective feeding, and ease of operation, as shown in Figure 4.

Figure 4: Top-Gating System for Cylinder Head Casting

(Insert image of the top-gating system)

2.3 Virtual Design and Simulation

We utilized simulation software such as Magma and ProCAST to analyze the flow field and temperature field during filling and solidification. This enabled optimization of the gating system, determination of the final feeding strategy, and calculation of casting process parameters like gating system proportions and in-gate velocities. The simulation results were used to verify and improve the casting process.

2.4 Sand Mold Design and 3D Printing

Using 3D CAD software, we designed the sand mold incorporating the gating system, considering factors such as 3D printing capabilities, equipment limits, and product structure. The objective was to minimize the number of cores while avoiding obstructions during core cleaning. The cylinder head casting and gating system could be fully formed by three 3D-printed sand molds, assembled as shown in Figure 5.

Table: Comparison of Traditional and 3D Printing Casting Processes

| Aspect | Traditional Casting | 3D Printing Casting |

|---|---|---|

| Core Quantity | Multiple (20 cores) | Minimal (3 cores) |

| Dimensional Accuracy | Low | High |

| Production Cycle | Long (60 days) | Short (7 days) |

| Manual Intervention | High | Low |

| Finished Product Rate | Lower | Higher |

Figure 5: 3D Printing and Assembly of Sand Molds

(Insert image of the 3D-printed and assembled sand molds)

2.5 Casting Cleanup

After pouring and cooling, the casting was removed from the mold once it reached the required cooling time. The casting exhibited clear contours and minimal flashing. After shot blasting and minor finishing, a complete毛坯cylinder head casting was obtained.

3. Advantages of 3D Printing Casting Process

3.1 Simplification of Complex Structures

The 3D printing sand mold design eliminates the need for mold splitting and core extraction considerations, simplifying the process design. Complex structural cores can be printed as a single unit, significantly reducing the number of cores.

3.2 Shorter Production Cycle and Enhanced Efficiency

Compared to traditional mold production processes, including mold making, molding, core making, mold assembly, and pouring, which can take up to 60 days for a single cylinder head, the 3D printing process shortens the cycle to just 7 days. With fewer manual operations, the influence of human factors on product quality is minimized.

3.3 Higher-Quality Casting Products

As shown in Figure 6, the advantages of 3D printing for cylinder head production are evident. The number of cores is reduced from 20 to 3, an 85% decrease, which not only simplifies operations but also significantly reduces flashing. The high precision of 3D printers ensures high-dimensional accuracy of the sand cores, reducing casting dimensional errors by over 75% and enhancing product quality and yield rates. The mold-free and mold-box-free production characteristics decrease the production cycle by 88%. High-quality, high-precision castings reduce finishing time and difficulty, enabling the casting to move from mold opening to warehousing within a day.

Figure 6: Advantages of 3D Printing Casting Process for Cylinder Heads

(Insert image showing a comparison of traditional and 3D-printed casting processes)

| Advantage | Details |

|---|---|

| Complexity Simplification | Reduction in core count, simplification of process design |

| Shortened Cycle Time | Production cycle shortened from 60 days to 7 days |

| Higher-Quality Castings | Improved dimensional accuracy, reduced flashing, enhanced product quality |

4. Conclusion

Traditional casting methods for cylinder head castings face challenges such as poor product quality, difficult quality control, high worker labor intensity, and safety hazards associated with crane operations. The 3D printing casting process for sand cores offers several advantages, including high-dimensional accuracy, minimal flashing, superior aesthetics, ease of cleanup, reduced machining requirements, lower worker labor intensity, streamlined processes, and reduced safety risks associated with manual handling and crane operations. With its wide potential for adoption, 3D printing is poised to revolutionize casting production methods, driving the transformation of traditional casting factories towards digitization, green production, and intelligence.