Ductile cast iron is highly valued for its exceptional mechanical properties, including high strength, ductility, and toughness. However, its performance in aggressive environments is often challenged by various forms of corrosion. This article explores the corrosion resistance of ductile cast iron, the specific challenges it faces in aggressive environments, and strategies to mitigate these issues to enhance its durability and reliability.

Introduction

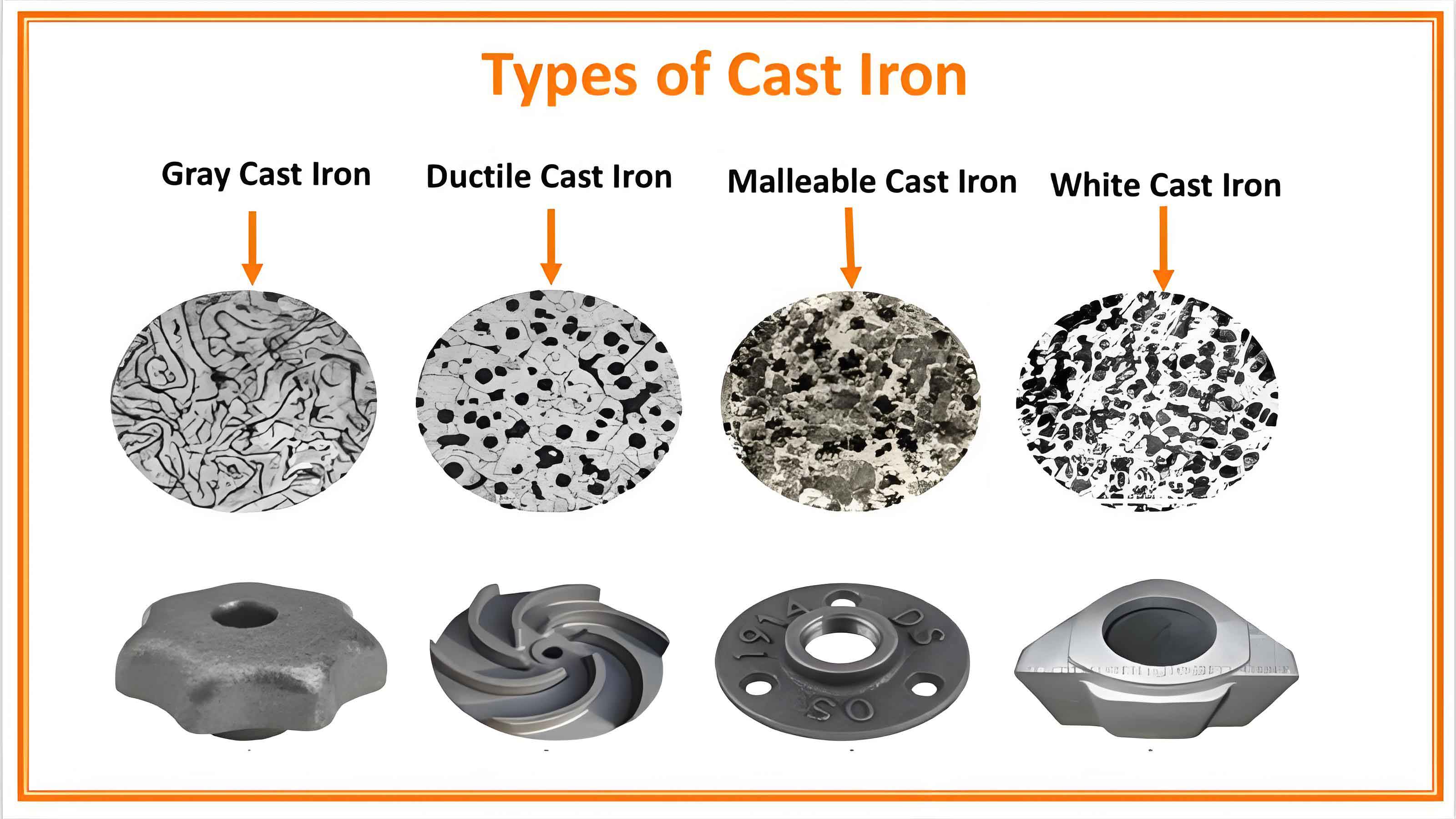

Ductile cast iron, also known as nodular cast iron or spheroidal graphite iron, is a type of cast iron characterized by its graphite nodules. These nodules enhance the material’s mechanical properties, making it suitable for a wide range of industrial applications. Nevertheless, its exposure to aggressive environments can lead to significant corrosion, which impacts its performance and lifespan.

Factors Influencing Corrosion Resistance

Several factors determine the corrosion resistance of ductile cast iron, including its microstructure, composition, and the specific characteristics of the environment in which it is used.

Microstructure

The microstructure of ductile cast iron consists of spherical graphite nodules within a ferritic, pearlitic, or bainitic matrix. The presence of these nodules helps reduce stress concentration, which can otherwise accelerate corrosion.

Composition

The chemical composition of ductile cast iron, including the presence of alloying elements such as silicon, manganese, and phosphorus, significantly affects its corrosion resistance.

Table 1: Effect of Alloying Elements on Corrosion Resistance

| Element | Effect on Corrosion Resistance |

|---|---|

| Silicon | Forms a protective oxide layer, enhancing corrosion resistance |

| Manganese | At high levels, it can reduce corrosion resistance |

| Phosphorus | Increases brittleness, potentially lowering corrosion resistance |

Environmental Factors

Environmental factors, such as pH, chloride concentration, temperature, and the presence of corrosive agents, play a crucial role in the corrosion behavior of ductile cast iron.

Table 2: Environmental Factors Affecting Corrosion Resistance

| Environmental Factor | Impact on Corrosion |

|---|---|

| pH | Acidic conditions (low pH) accelerate corrosion |

| Chloride Ions | High chloride levels increase the risk of pitting corrosion |

| Temperature | Elevated temperatures generally increase corrosion rates |

| Corrosive Agents | Presence of acids, salts, and gases (e.g., SO2) enhances corrosion |

Corrosion Mechanisms

Ductile cast iron can be susceptible to various types of corrosion, including uniform corrosion, pitting corrosion, and galvanic corrosion.

Uniform Corrosion

Uniform corrosion occurs evenly across the surface, leading to a gradual reduction in material thickness. This type of corrosion is common in acidic environments where the entire surface is exposed to corrosive agents.

Pitting Corrosion

Pitting corrosion is a localized form of corrosion that results in small, deep pits on the surface. It is particularly dangerous because it can lead to the rapid penetration of the material, causing structural failure. Chloride ions are a common cause of pitting corrosion in ductile cast iron.

Galvanic Corrosion

Galvanic corrosion occurs when ductile cast iron is in electrical contact with a more noble metal in the presence of an electrolyte. The electrochemical potential difference between the two metals causes the ductile cast iron to corrode preferentially.

Enhancing Corrosion Resistance

Several strategies can be employed to enhance the corrosion resistance of ductile cast iron, making it more suitable for use in aggressive environments.

Alloying

Incorporating specific alloying elements can improve the corrosion resistance of ductile cast iron. Elements such as chromium, nickel, and molybdenum are commonly added to enhance resistance to various corrosive environments.

Table 3: Effect of Alloying Elements on Corrosion Resistance Enhancement

| Alloying Element | Effect on Corrosion Resistance |

|---|---|

| Chromium | Improves resistance to oxidation and high-temperature corrosion |

| Nickel | Enhances resistance to acid and chloride-rich environments |

| Molybdenum | Increases resistance to pitting and crevice corrosion |

Surface Coatings

Applying protective coatings is an effective way to shield ductile cast iron from corrosive environments. Common coatings include epoxy resins, zinc coatings (galvanization), and ceramic coatings, which provide a barrier against corrosive agents.

Cathodic Protection

Cathodic protection involves the use of a sacrificial anode or impressed current system to prevent the corrosion of ductile cast iron. This method is widely used in pipelines and marine applications to protect against galvanic and uniform corrosion.

Environmental Control

Controlling environmental factors, such as reducing the exposure to corrosive agents and maintaining a neutral pH, can significantly mitigate corrosion. This can be achieved through the use of inhibitors, proper drainage, and controlled storage conditions.

Regular Maintenance and Monitoring

Implementing regular maintenance schedules and monitoring for early signs of corrosion can help identify and address issues before they become severe, thus extending the service life of ductile cast iron components.

Case Studies

Case Study 1: Water Treatment Facilities

In water treatment facilities, ductile cast iron pipes are often exposed to fluctuating pH levels and various chemicals. By applying epoxy coatings and using cathodic protection, the lifespan of these pipes has been significantly extended, reducing maintenance costs and downtime.

Case Study 2: Marine Environments

Ductile cast iron components used in marine environments face severe corrosion due to saltwater exposure. The application of zinc coatings and the addition of nickel to the alloy composition have proven effective in enhancing corrosion resistance, ensuring reliable performance in these harsh conditions.

Conclusion

The corrosion resistance of ductile cast iron in aggressive environments is influenced by its microstructure, composition, and environmental factors. Understanding these influences and implementing appropriate strategies, such as alloying, surface coatings, cathodic protection, and environmental control, can significantly enhance the durability and performance of ductile cast iron components. By adopting these measures, industries can extend the service life of their infrastructure and reduce maintenance costs, ensuring sustainable and reliable operations in challenging environments.