Certain type of 30t excavator has experienced several instances of cracking and failure of the front support during casting. The working time for cracking failure is around 3000h, which is much shorter than the design life and is considered an abnormal failure. After investigation, it was found that the main operating conditions were stone crushing, excavation, and loading in the mountains.

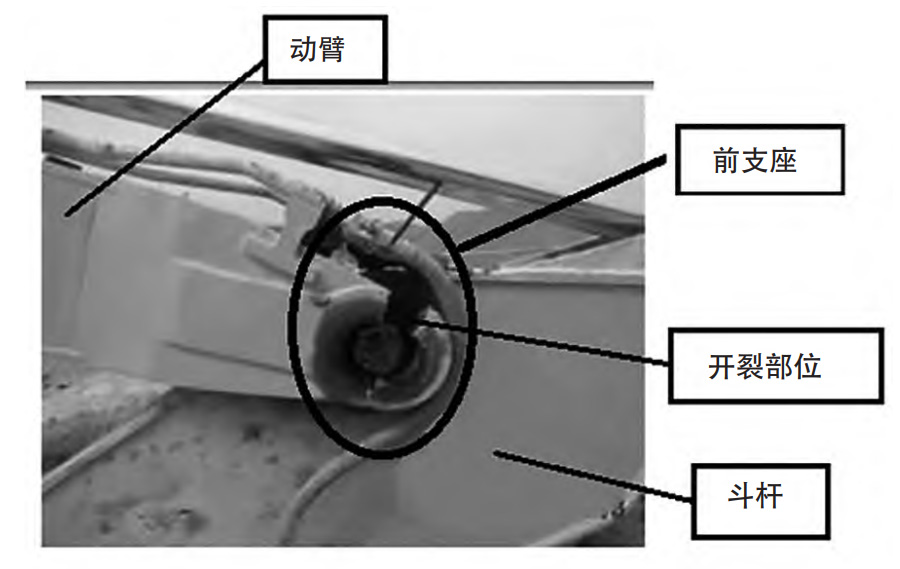

Through preliminary observation of the faulty parts, it was found that the failure modes of these several times were basically consistent, and the cracking areas were all located in the upper part of the front support steel casting hole. The crack location of the front support steel casting is shown in the figure. The front support steel casting is an important force transmission component in the excavator working device, which bears strong instantaneous impact loads during operation. Once it fails, it will cause serious consequences. This article conducts a failure analysis on one of the fractured front support steel castings in order to identify the root cause of the fracture and improve the reliability of the excavator structural components.