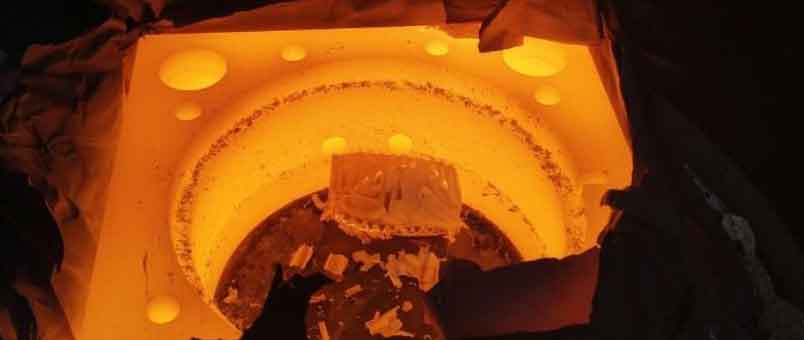

Quenching is a critical step in the heat treatment process that involves rapid cooling of the heated component to achieve the desired material properties. However, improper quenching can lead to various defects that can compromise the quality and performance of the heat-treated parts. Here are some crucial cooling considerations to help manage quenching defects:

1.Quenching Medium Selection:

Selecting the appropriate quenching medium is essential to achieve the desired cooling rate and minimize the risk of defects. Different quenching media, such as water, oil, polymer solutions, or gases, offer varying cooling rates and can affect the final material properties. Consider the material type, desired hardness, distortion susceptibility, and the specific requirements of the component when choosing the quenching medium.

2.Quenching Rate Control:

The cooling rate during quenching should be controlled to avoid rapid and uneven cooling that can lead to cracking or distortion. The cooling rate is influenced by factors such as the quenching medium, component geometry, and initial temperature. Adjust the quenching parameters, including immersion depth, agitation, or circulation, to achieve the desired cooling rate and minimize the risk of defects.

3.Adequate Agitation:

Agitation of the quenching medium promotes efficient heat transfer and helps prevent the formation of vapor or gas barriers around the component surface. Proper agitation ensures uniform cooling and reduces the likelihood of surface defects. Methods such as stirring, jet impingement, or mechanical movement can be employed depending on the quenching medium and component geometry.

4.Precooling or Intermediate Cooling:

For materials with a high risk of cracking or distortion, precooling or intermediate cooling steps can be introduced. Precooling involves reducing the component temperature to a certain level before the actual quenching process, while intermediate cooling involves interrupting the quenching process for a short period to allow for stress relief. These techniques can help manage thermal stresses and minimize the risk of defects.

5.Quenching Fixture Design:

The design and selection of quenching fixtures or jigs are crucial for controlling distortion and preventing localized cooling or stress concentration. Consider factors such as component support, minimizing contact areas, and ensuring adequate cooling fluid circulation around the component. Well-designed fixtures can help maintain dimensional stability and minimize the risk of quenching defects.

6.Temperature Control:

Monitoring and controlling the temperature during the quenching process is important to achieve consistent and desired cooling rates. Use accurate temperature measurement techniques, such as thermocouples or infrared sensors, to monitor the component temperature during quenching. Adjust the quenching parameters if necessary to maintain the desired temperature range.

7.Post-Quenching Treatment:

Depending on the material and desired properties, post-quenching treatments such as tempering or stress relieving can be applied. These treatments help alleviate residual stresses, enhance material toughness, and minimize the risk of quenching-induced defects.

8.Quality Control and Inspection:

Implement rigorous quality control measures to detect and address quenching defects. Conduct visual inspections, non-destructive testing techniques (e.g., dye penetrant testing, magnetic particle inspection), and dimensional checks to identify any surface cracks, distortions, or dimensional deviations resulting from quenching.

It is crucial to consider the specific material, component geometry, and heat treatment requirements when managing quenching defects. Collaboration with heat treatment experts, metallurgists, and process engineers can provide valuable insights and guidance in optimizing the quenching process to minimize defects and achieve the desired material properties.