2.7 CTI diesel engine cylinder block is an in-line four cylinder engine. The casting brand is HT250, the blank mass is about 78 kg, and the maximum outline size is 465 mm × 400 mm × 260 mm, gravity casting structure is shown in Figure 1. The product adopts the green sand gravity casting process, with a layout of two pieces for one type. The water jacket sand core is 475 mm long, and the minimum wall thickness is 3 mm (three inter cylinder cooling troughs with long cross section are formed). The triethylamine cold core making method is adopted, and the structure is shown in Figure 2.

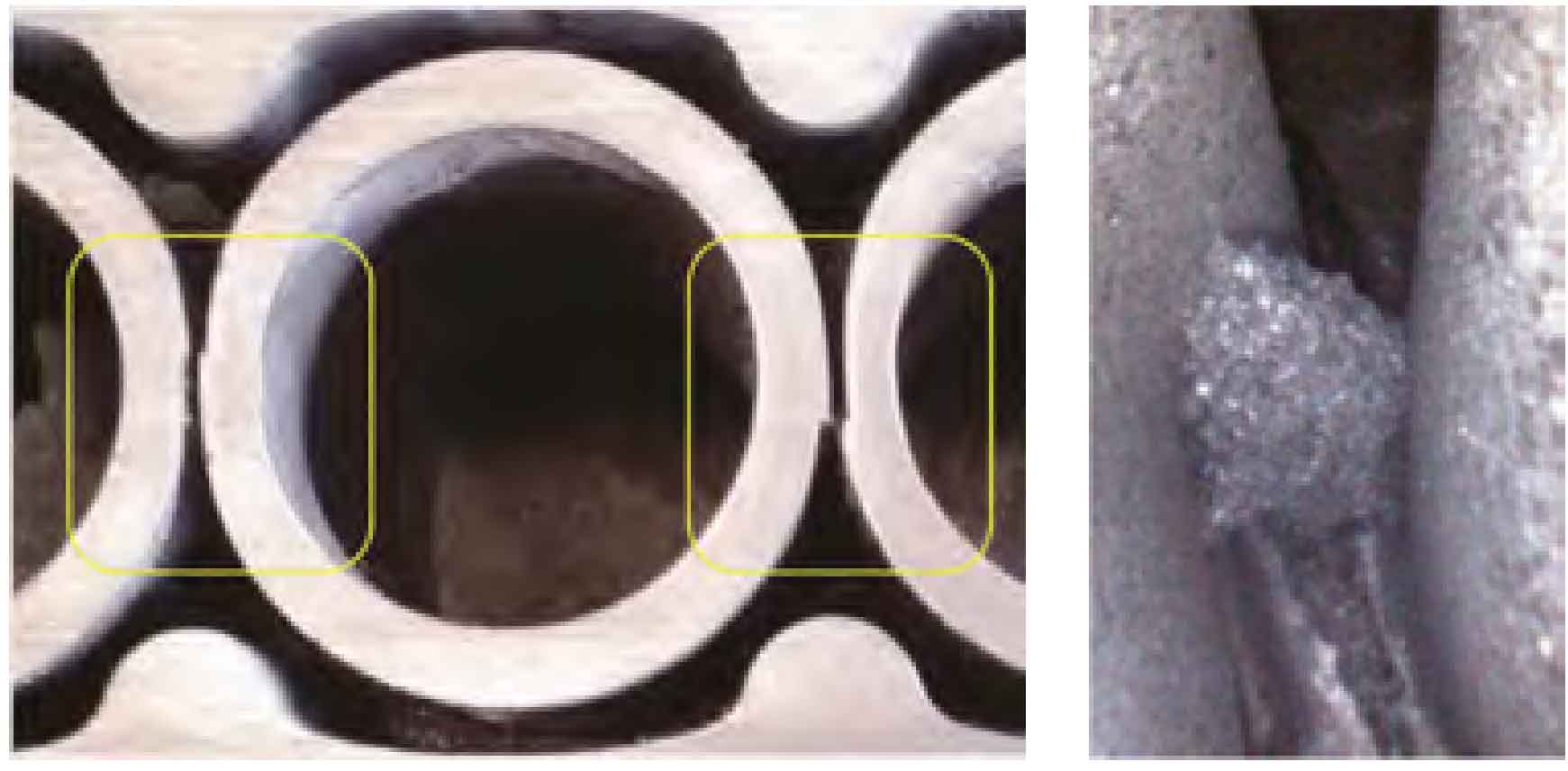

In the R&D and trial production stage, there is a common sand sticking phenomenon in the inner cavity of the cylinder water jacket, which is concentrated in the narrow gap between the two cylinders. Through further product cutting and wall thickness detection, it is found that the wall thickness uniformity of the cylinder hole along the length direction is poor, and in serious cases, “step” phenomenon can be seen on the outer wall of the cylinder hole (caused by the fracture of the middle thin wall of the water jacket sand core). The water jacket core breaking and sand sticking defects are shown in Figure 3. In addition, there are also problems of difficult sand production in the inner cavity of the water jacket and easy attachment of “black ash” on the inner wall, which bring troubles to the cleaning and quality control of the subsequent gravity castings, and there are major quality hazards.

In view of the above problems, the process control elements strongly related to the quality of the inner cavity were analyzed, and a series of measures were taken to finally obtain high-quality gravity castings with smooth and clean inner cavity of the water jacket and qualified dimensions, which met the needs of mass production of products.