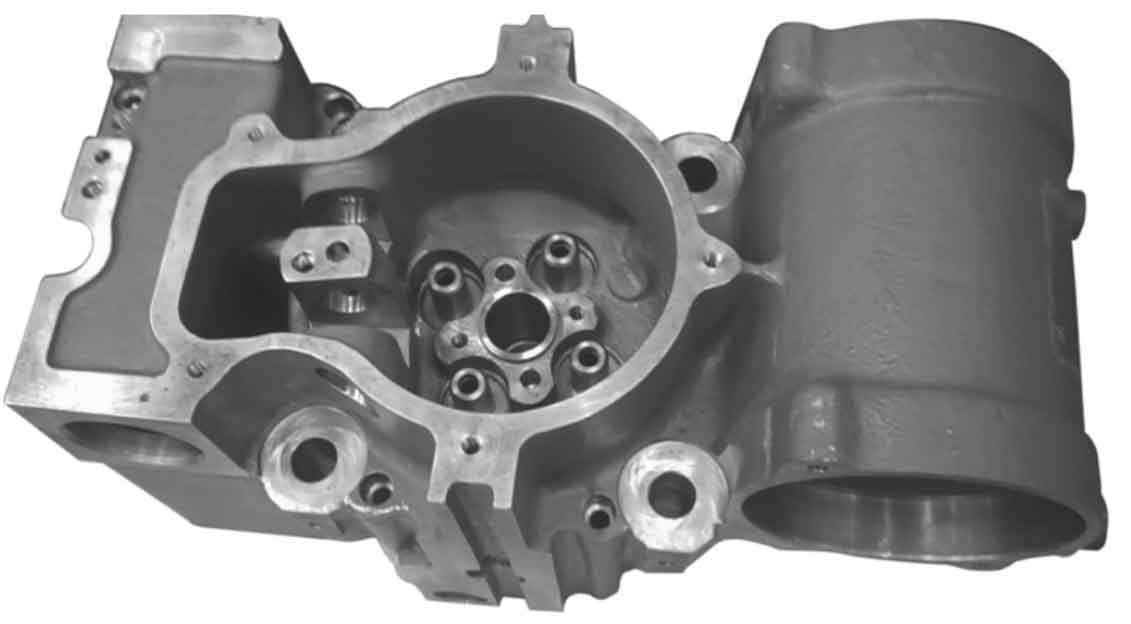

The cylinder heads of high-speed and heavy-duty marine diesel engines are mostly high toughness ductile iron (see Figure 1). The cooling solidification mode of nodular cast iron is paste solidification, which is easy to produce defects such as small number of graphite balls, large ball diameter, low mechanical properties, spheroidization recession and incubation recession. In addition, the cylinder head is traditionally produced by vermicular cast iron, but now it is produced by nodular iron. Due to its complex structure and difficult to control the cooling and solidification speed of each part, it is particularly difficult to cast, and it is easy to produce casting defects such as leakage.

1 Problem description

From trial production to mass production of high toughness ductile iron cylinder head, the product quality fluctuates greatly, and the yield is less than 80%. The main defects leading to low yield are: shrinkage in the valve guide hole, shrinkage in the bolt hole, air holes around the oil injection hole, shrinkage at the edge of the gate in the exhaust pipe, air holes, etc.

2 Analysis and solution of casting defects

2.1 Analysis and solution of shrinkage casting defects

2.1.1 Cause analysis

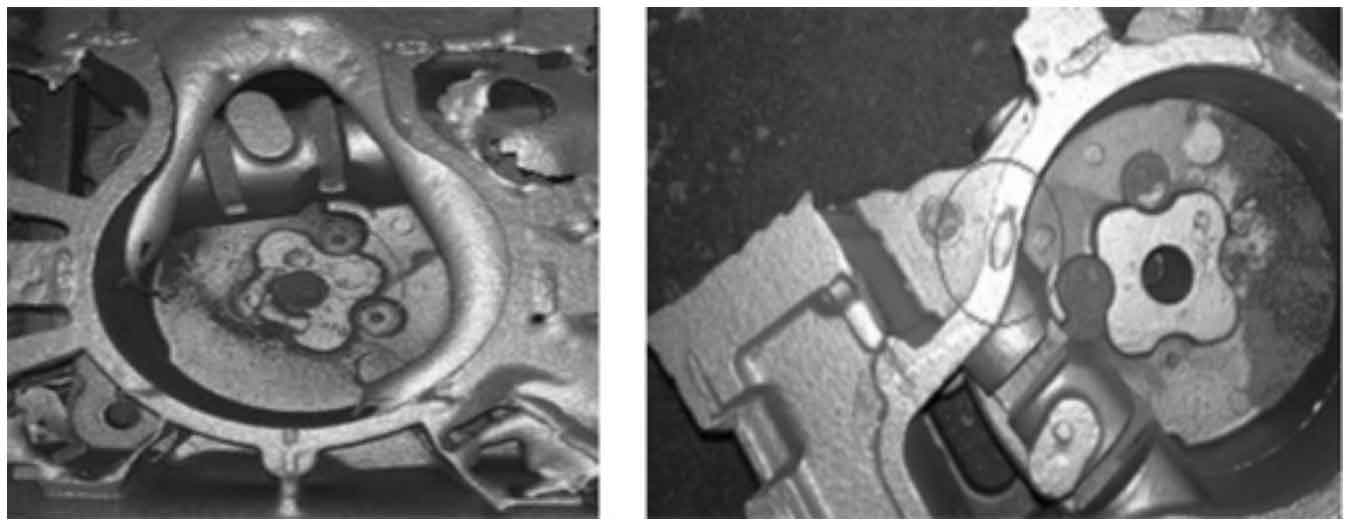

This type of cylinder head integrates the intake pipe and rocker shaft seat on the basis of the traditional cylinder head. It has a compact structure and forms many isolated hot joints. It is difficult to control the cooling and solidification speed of various parts during the cooling and solidification of the casting, and the casting measures that can be taken are limited. Therefore, there is no hot metal for feeding during the solidification of hot joints in valve guide holes, bolt holes and other parts, resulting in shrinkage cavities and Shrinkage casting defects (see Figure 2).

2.1.2 Solutions

(1) Place in the valve guide hole Φ 25mm × 60mm round steel cold iron is preset in the duct hole on the upper part of the exhaust duct Φ 8mm internal cold iron, the hole core of the fuel injector is changed from ordinary coated sand to chromite sand with high heat storage coefficient, and the fuel injection hole is changed from graphite to chromite coated cold iron, so as to speed up the cooling speed of the heat section in this part and advance its graphitization expansion.

(2) Φ Chromite sand coated cold iron shall be set at the 25mm bolt hole, and the sand coated layer shall be controlled within 6mm ~ 8mm.

(3) An external cold iron is set at the edge of the inner gate of the intake pipe flange to speed up the heat transfer.

2.2 Pore casting defect analysis and Solutions

2.2.1 Cause analysis

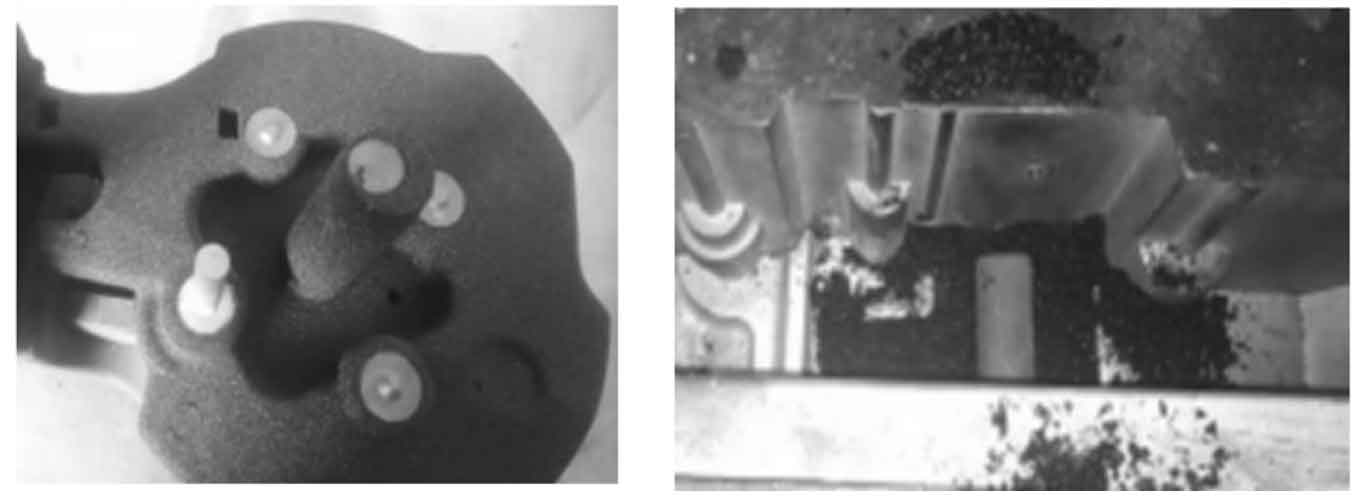

This type of cylinder head has special structure, high integration and complex production process. The number of sand cores is up to 27, and the sand cores in the inner cavity are made of hot core box coated sand. A large amount of gas generated by heating during molten iron pouring can not be completely discharged into the cavity, which invades the cavity to form pore casting defects (see Fig. 3).

2.2.2 Solutions

(1) After the sand core of the injector hole is soaked, coated and dried, it is baked at low temperature. The baking temperature is set at 180 ℃ and the baking time is 4H to reduce the gas output of the sand core.

(2) Before lowering the core of each coated sand core, drill a vent hole at the core head and lead the vent hole out of the mold.

3 Scheme implementation and effect verification

3.1 Scheme implementation

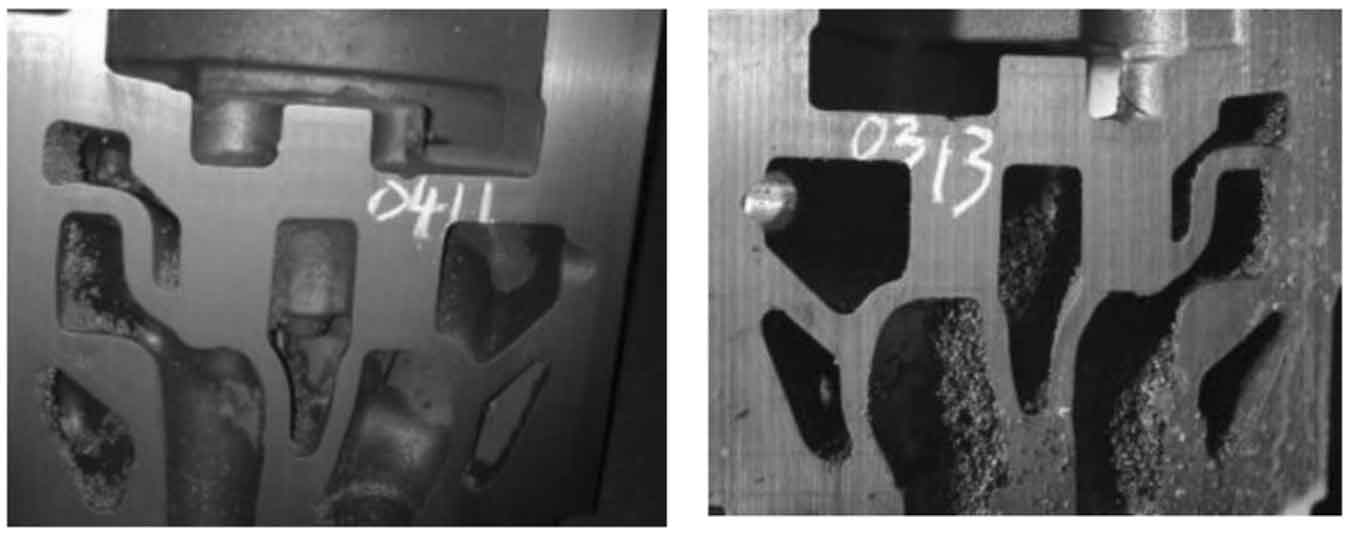

The production preparation shall be carried out according to the established scheme. Since the hole core of the fuel injector is made of film coated sand in the hot core box, and the sand shooting and mold lifting are completed by mechanical automation, the set cold iron shall be positioned in the core box, and the groove to increase the adhesion of the core sand shall be processed on the cold iron to prevent the cold iron from shifting and falling off during core making. Therefore, the cold iron is specially designed and processed to ensure the quality of sand core. After the completion of production preparation, the first test was conducted and the implementation of measures was checked (see Figure 4).

3.2 Effect verification

20 cylinder heads were tested for the first time according to the formulated scheme. After cleaning, the surface quality of the castings was good, and there were no air hole casting defects. One piece was randomly inspected for physical sectioning, and there were no shrinkage and cavity casting defects (see Fig. 5). The casting quality fully met the product technical requirements.

Up to now, 400 cylinder heads have been produced according to this scheme, and 8 waste products have been produced, with a yield of 95%.

4 Conclusion

For castings with complex structure and high internal quality requirements, when the structure is limited and direct feeding measures cannot be taken, special sand combined with cold iron process can accelerate the cooling speed of local hot joints, eliminate shrinkage cavities and porosity, and effectively solve the casting defects of shrinkage cavities and porosity at hot joints.