The pyramid lattice sandwich structure with core member length L = 32mm, core and panel angle w = 60 ° and core member section radius r = 1.5mm was selected for investment casting simulation experiment. With the help of ProCAST platform, the filling, solidification process and defects of lattice sandwich structure are studied by numerical simulation, which has guiding significance for the actual production of lattice sandwich structure. The experimental process and results are as follows.

In view of the characteristics of single lattice sandwich structure, such as complex core twists and turns and thin panel, a comprehensive pouring system combining bottom injection and vertical gap type is adopted to ensure the stable and complete filling of the mold cavity by liquid metal. As a common gating system for non-ferrous metal castings, the slot gating system can realize the sequential filling of liquid metal layer by layer, while the bottom injection slot gating system has a slow filling speed under the action of gravity. When entering the mold cavity, the liquid metal filling is stable and rises slowly, and the impact on the mold shell is small, which is very conducive to the filling. For the design of slot gating system, it is generally designed according to the following principles:

(1) The number of columns and vertical joints is jointly determined by the overall dimensions and technical requirements of investment castings. If the accuracy requirements of investment castings are relatively high, the number of columns and vertical joints can be appropriately increased. In general, it can be determined by empirical formula:

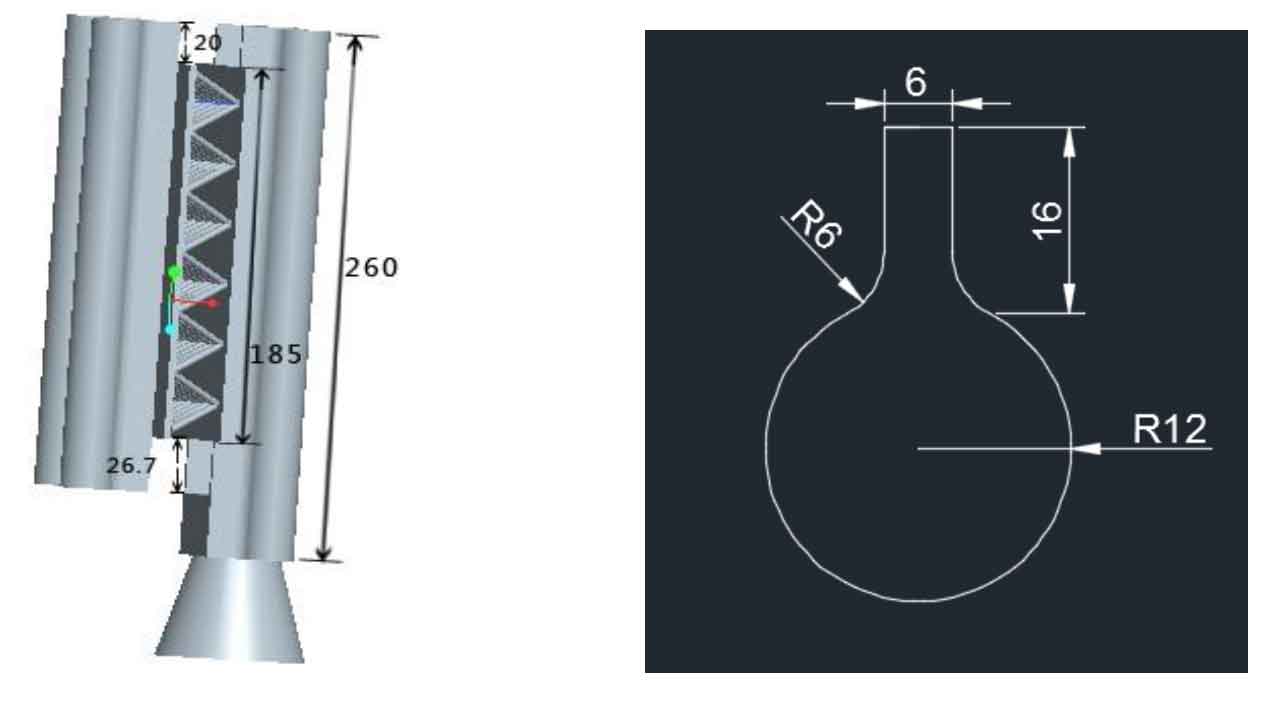

Where, n is the number of gaps; S is the overall dimension of investment casting; δ Is the thickness of the sprue in the gap; δ Casting is the wall thickness of the investment casting at the joint with the gap sprue; B is the width of the sprue in the gap; D is the diameter of the gap riser.

(2) The gate cup, runner and sprue can be designed according to the traditional design principles of gating system. However, the position of the inner gate has a great impact on the function of the slot gating system. Generally, the inner gate is placed at the lower part of the column. In order to avoid the pouring liquid entering the cavity immediately after entering the column, but showing an upward trend, the column should be 20 ~ 30mm lower than the bottom of the investment casting. In addition, in order to fully fill the mold of the investment casting, the column shall be 10 ~ 20mm higher than the upper part of the investment casting.

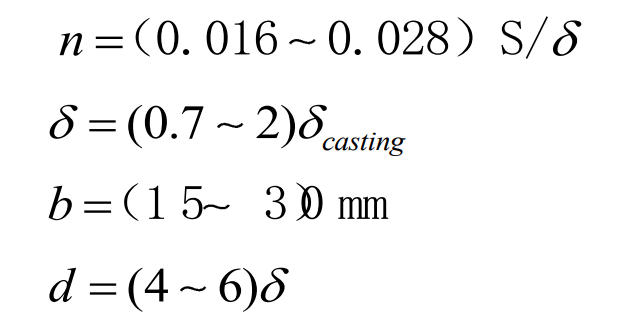

According to the above design principles and the dimensions of Lattice Sandwich Panel investment casting, the number of columns n = 2 ~ 4 can be calculated; The gap thickness is 2.1 ~ 6mm. In this paper, the lattice sandwich structure has dense cores. In order to better fill the mold, the gap thickness of the gating system is 6mm and the column diameter is 24mm. Taking the double gap gating system as an example, the specific dimensions are shown in Figure 1.

According to the characteristics of slot gating system, three types of gating systems are designed according to the number of columns, as shown in Figure 2.

Gating system I: double gap gating system, as shown in Figure 2 (a). Two gaps are set on one side of the gating system, and two columns are set opposite the gap. The function of the columns is to store the pouring liquid and prevent the incomplete filling of investment castings; Stiffeners and air passages can also be placed to improve the exhaust quality and the quality of investment castings.

Gating system II: three slot gating system, as shown in Fig. 2 (b). In order to avoid the metal liquid opposition of vertical joints on both sides of the lattice sandwich structure panel, resulting in unstable metal liquid filling, the three columns are staggered.

Gating system III: four slot gating system, as shown in Fig. 2 (c), the gate is set in the middle and the columns are placed relatively.

The lattice sandwich structure material is IN718 superalloy, and its thermophysical parameters are shown in the table below. The experiment adopts zirconia ceramic shell investment casting, which is cooled under vacuum. The shell thickness is 8mm, the heat transfer coefficient at the interface between zirconia ceramic shell and investment casting is 700W / (m · K), the pouring temperature is 1450 ℃, the pouring speed is 80mm / s, and the preheating temperature of the shell is 600 ℃.