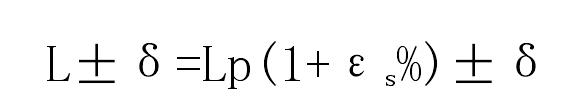

Nominal dimension of die cavity of investment casting impeller blade L:

Where LP – average dimension of investment casting impeller blade, LP = l ± Δ/ 2 (L – nominal size on investment casting impeller blade; Δ— Algebraic sum of upper and lower tolerances);

δ— Manufacturing tolerance is generally 1 / 3 ~ 1 / 5 of the dimensional tolerance of investment casting impeller blade. In the design process, in order to ensure that the dimensional tolerance reaches cT4 ~ CT5, the dimensional tolerance of investment casting impeller blade is selected according to CT3.

In production, it is difficult to design the size of the die cavity of the investment casting impeller blade correctly at one time. It is often necessary to correct the size of the die of the investment casting impeller blade through trial production after the die is made. Because the die is mainly corrected by cutting, the dimension forming the outline of the casting is taken as a smaller value in the design ε S real value, so that the die cavity of investment casting impeller blade is slightly smaller; The size of the inner cavity of the casting is larger ε S value, so that the size of the protruding part on the core or cavity is slightly larger for cutting and trimming. Therefore, when designing and manufacturing the pressure mold of investment casting impeller blade, the correction allowance should be reserved in advance, and the pressure mold size can be finally determined after repeatedly pressing the investment mold, measuring and modifying the impeller blade.