Because the cast impeller is a medium-sized casting, its structure is relatively simple, and it is mass production. Its parting surface is selected to be located at the largest section of the casting, and the thick cylinders are located above, which is convenient to set the riser for the feeding of the casting. The design of casting impeller gating system includes the selection of gating system type, the selection of ingate in the position of casting impeller, and the calculation of cross-sectional area of choke section, sprue, cross sprue and ingate.

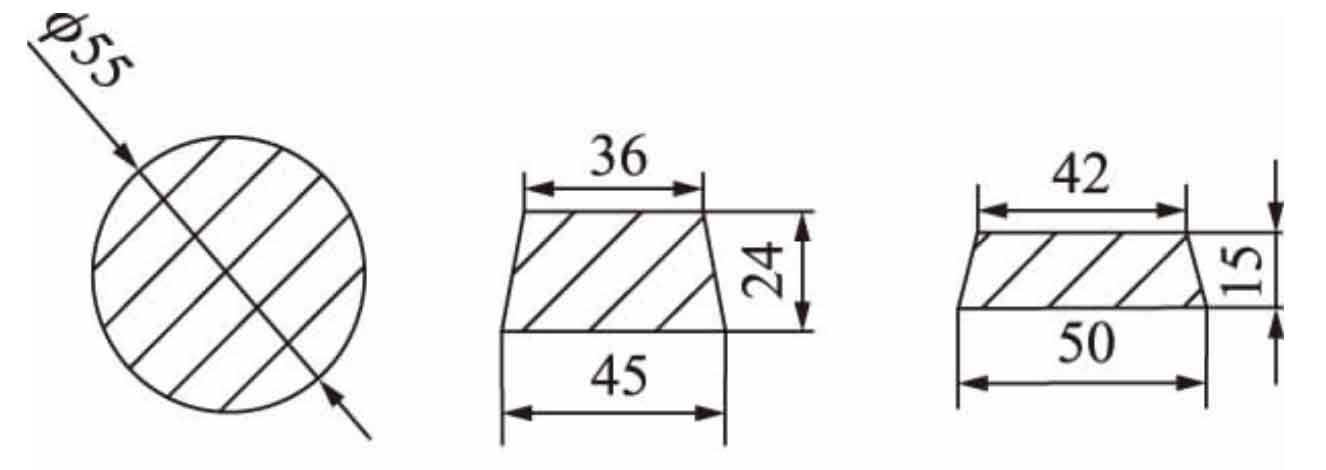

According to the characteristics of the structure and materials of the cast impeller, the reasonable design of the cast impeller gating system can make the mold filling relatively stable, and has little scouring ability to the mold cavity and the possibility of air entrainment, and the silicon aluminum alloy is not easy to oxidize. Therefore, the pouring system of casting impeller is the open pouring system, so that the cross-sectional area ratio of each component can be determined: Σ Straight: Σ Horizontal: Σ Internal = 1:2:3, so the size of each sprue can be determined, as shown in Figure 1.

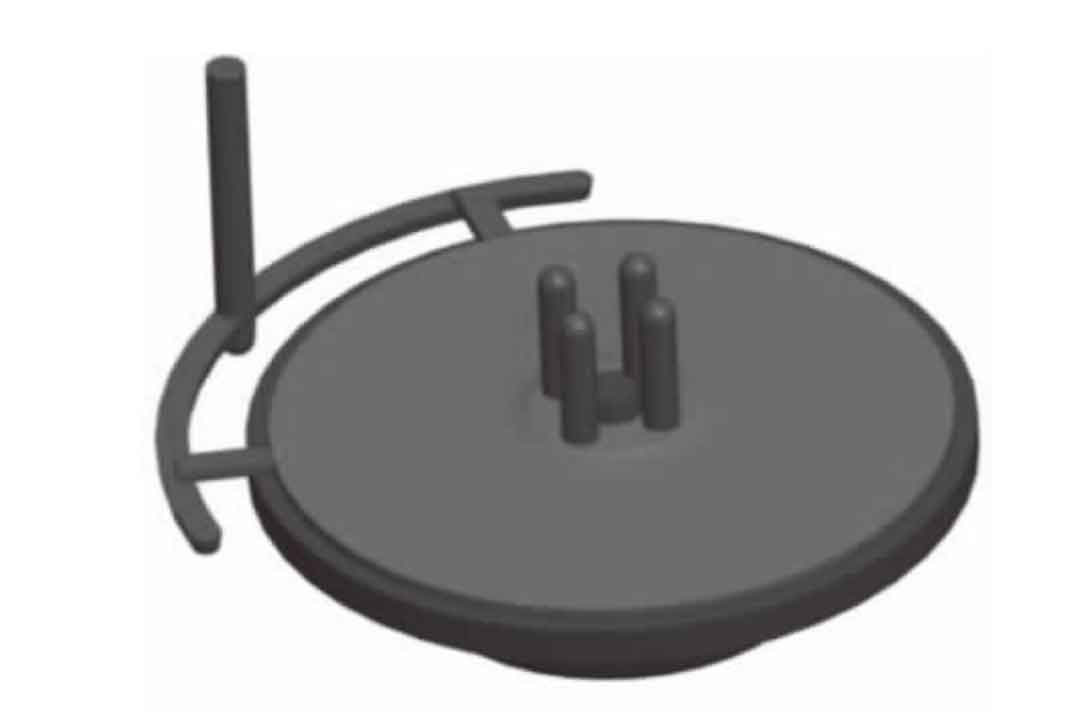

The position of the riser of the casting impeller shall be located at the highest and last solidification position of the casting, and shall not be placed at the stress concentration of the casting impeller, so as to effectively avoid the deformation or cracking of the casting impeller caused by heat difference; At the same time, it shall be located on the machining surface as far as possible to reduce unnecessary machining and trimming of the cast impeller. Therefore, the size of the riser can be determined from the casting manual, so as to obtain the 3D drawing of the casting process of the impeller, as shown in Figure 2.

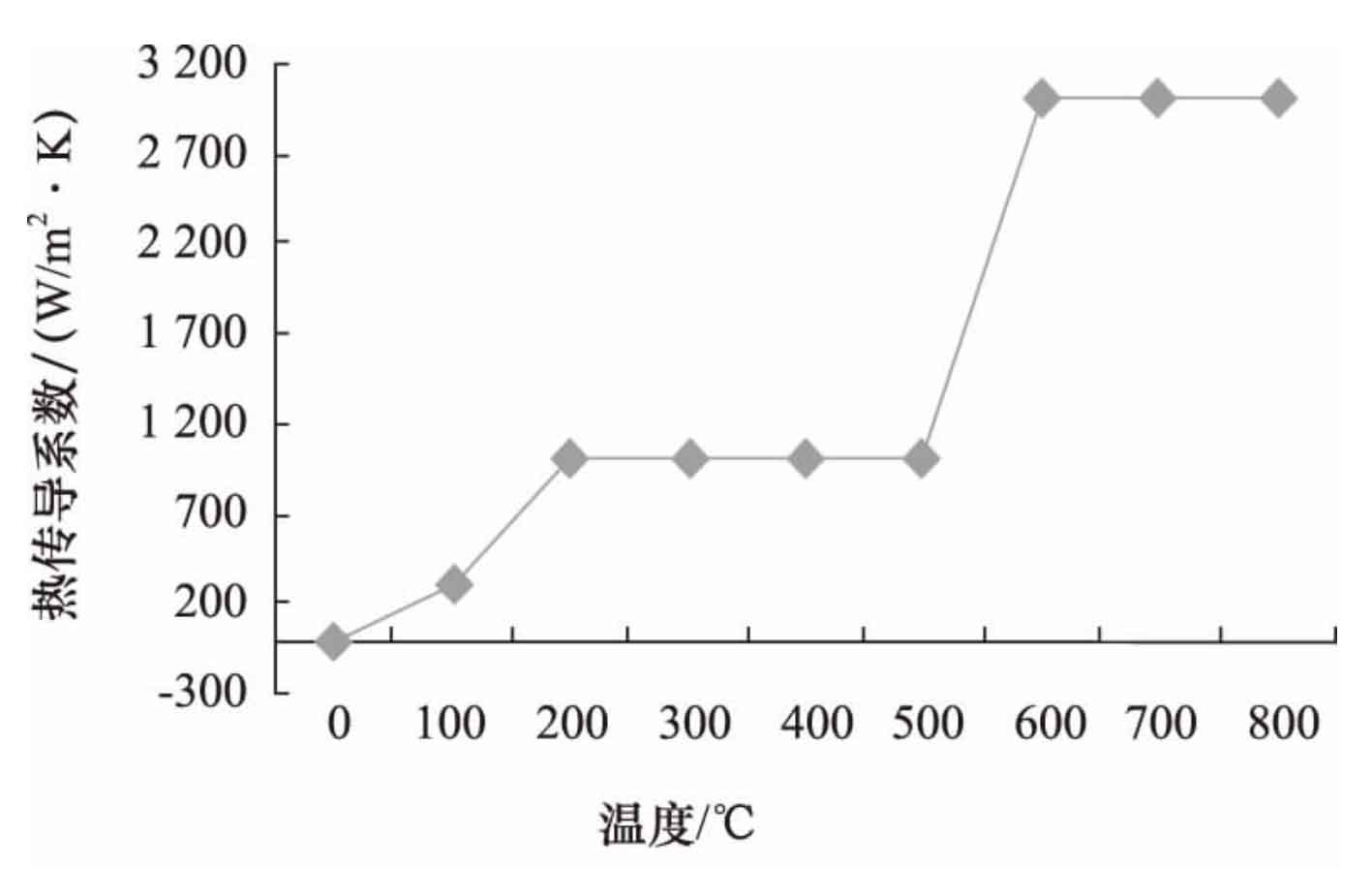

Referring to the casting impeller process, it can be seen that the solidus temperature of silicon aluminum alloy is 520 ℃ and the liquidus temperature is 590 ℃. At the same time, the fluid flow model of casting impeller is adopted, with CSF surface tension model and standard k-e turbulence model as the standard; The relationship between temperature and thermal conductivity of silicon aluminum alloy is shown in Figure 3.