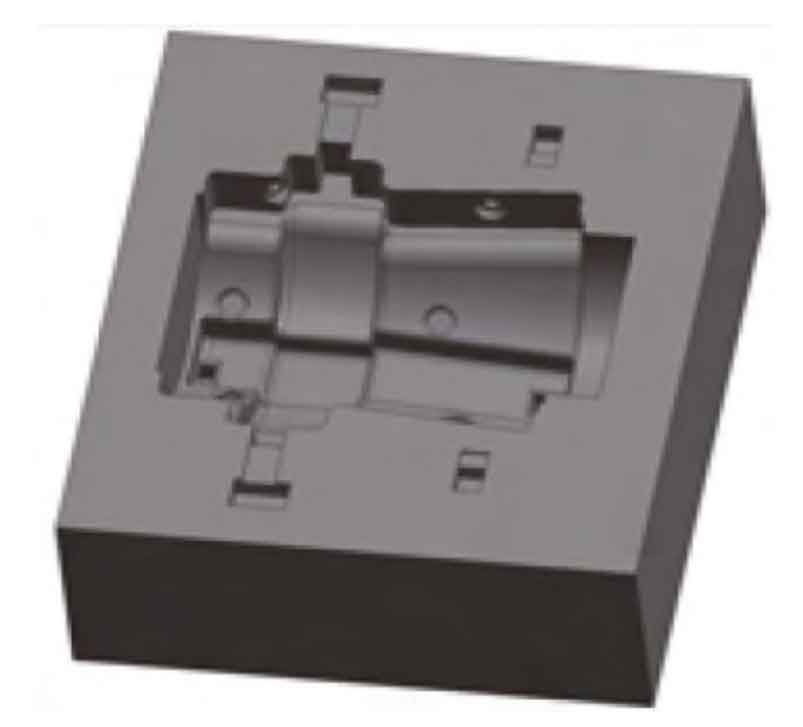

Due to the adoption of a wall riser process for the medium pressure inner cylinder steel casting, the main core cannot adopt the traditional two-end core method, so a shoulder type sand core structure is adopted.

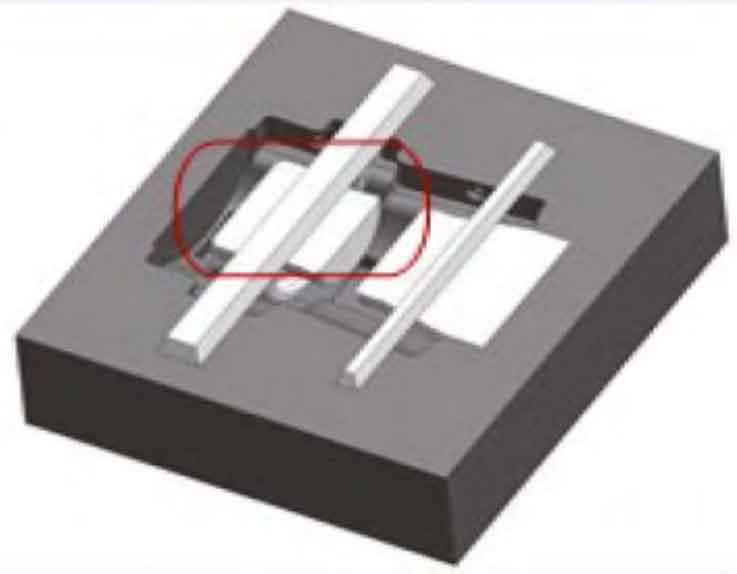

Core head positioning is required at both ends of the stretcher to ensure the accurate position of the sand core in the steam inlet chamber. The sand core in the red area has no fulcrum to ensure levelness, which is prone to sand core tilting. Therefore, the burden needs to be made into a flat type to increase its stability. The sand core and sand mold structures of steel castings are shown in Figure 1 and Figure 2.