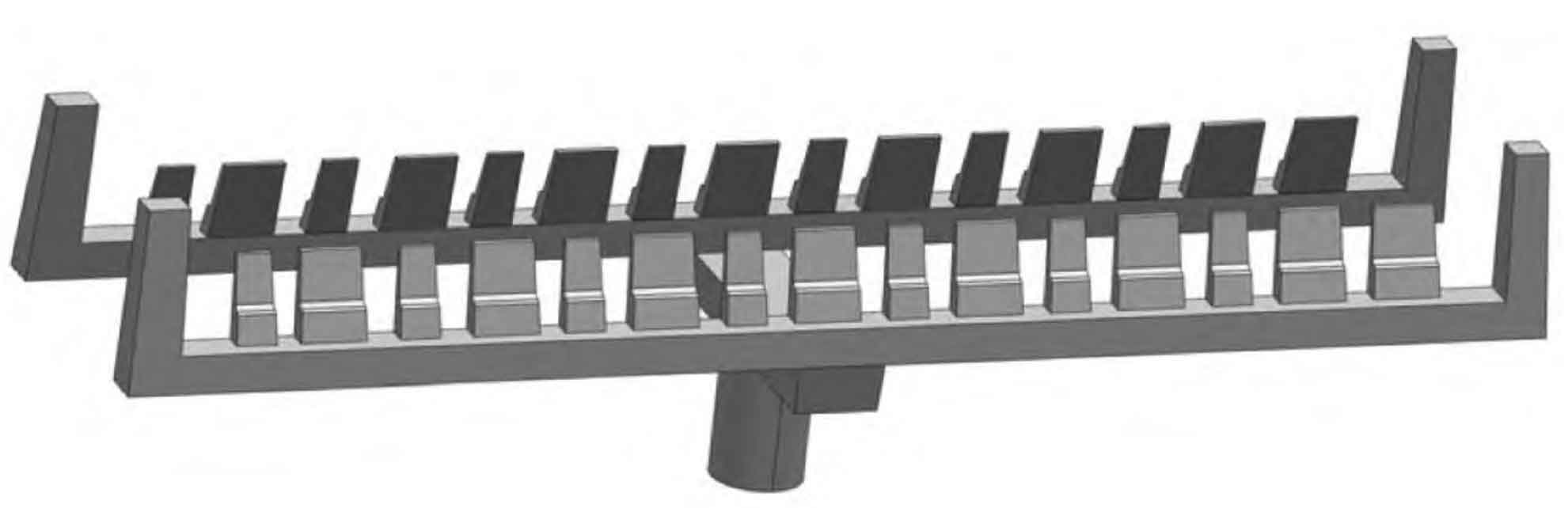

The existing low pressure casting process of cylinder head is improved, and the casting process plan of cylinder head is formulated mainly for the problems of loose position of main wire pair on the top plane and air hole. The improved casting process of cylinder head is shown in Figure 1.

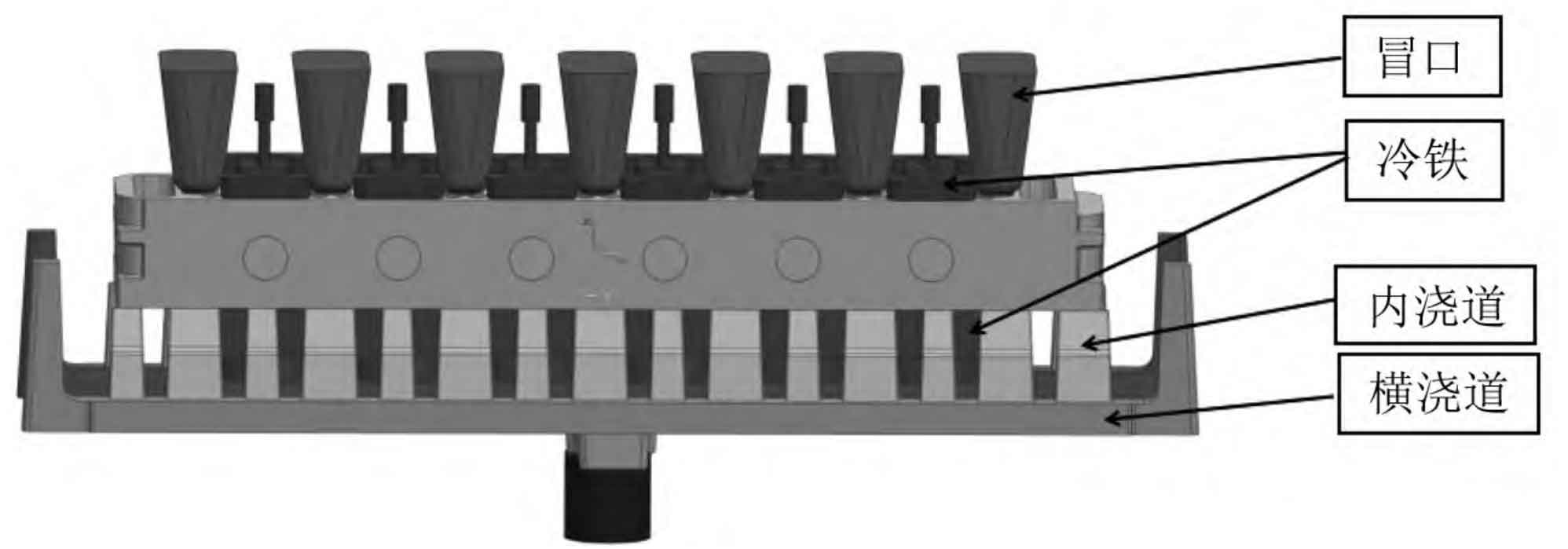

In order to ensure the smooth filling of molten metal, the pouring system is designed as an integral open type. The inner runner is designed at the hole where the large pair of wires are aligned with the thick surface of the combustion chamber. The shape of the inner runner is flat, with a total of 30 places on both sides. The large inner runner is set at the wall thickness, and the small inner runner is set at the wall thickness, and the pouring temperature is increased from 680 ℃ to 710 ℃. The section ratio of gating system: A lifting liquid: Σ A horizontal: Σ A internal=1 ∶ 1 ∶ 1.5, and the gating system is shown in Figure 2. According to the simulation results of MAGMA software, the filling rate of molten metal during the filling process is observed. The improved cylinder head casting process is not easy to form turbulence in the pouring process, thus avoiding the risk of inclusion and sand inclusion.