The combustion chamber surface of the cylinder head bears the thermal-mechanical alternating load and has high requirements for performance and defects. In order to improve the mechanical properties and internal quality of the combustion chamber surface, the thickness and material of the cold iron are optimized. The shaped copper cold iron with high thermal conductivity is selected. The thickness of the cold iron is changed to 110 mm. A large area of rapid cooling is carried out under the cylinder head casting to promote the bottom-up solidification starting point, The improved cylinder head casting process was simulated by MAGMA casting process simulation software, and no porosity and shrinkage defects were found.

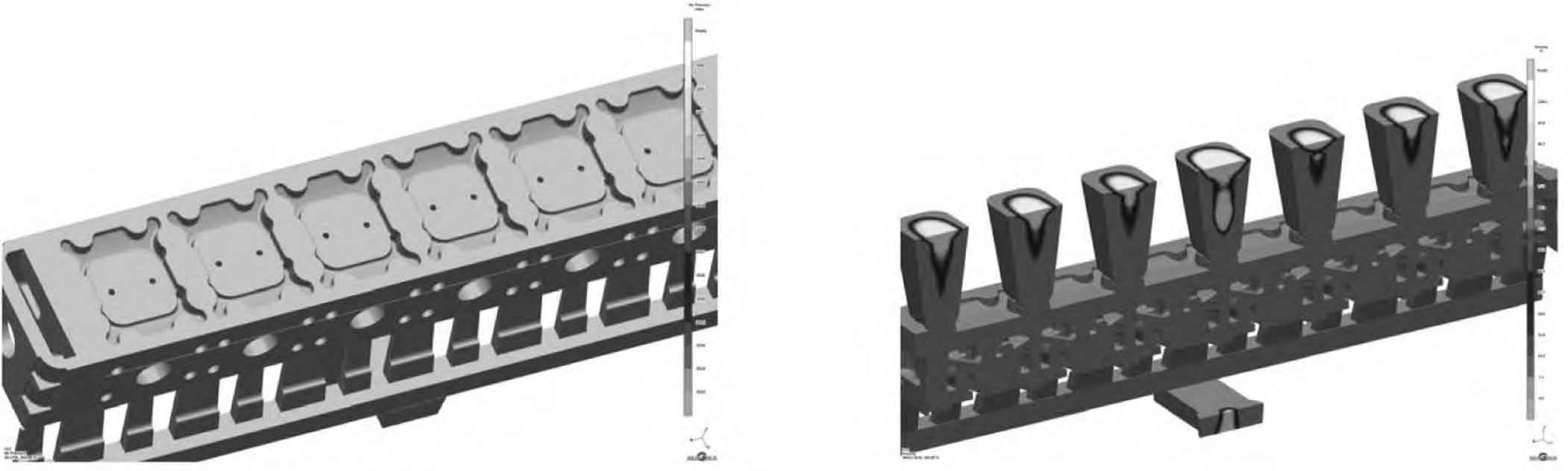

By using simulation software to simulate and calculate the optimized cylinder head casting process, and analyzing the pressure field and temperature field during the filling process and solidification process respectively, the risk of gas retention on the upper plane of the cylinder head casting is reduced, and there is almost no gas retention. As shown in Figure 1a, the thick and large hot spots of the cylinder head casting form a bottom-up solidification sequence, and the thick and large hot spots are fully compensated, The internal defects of the cylinder head casting disappear under the computer simulation state, as shown in Fig. 1b.

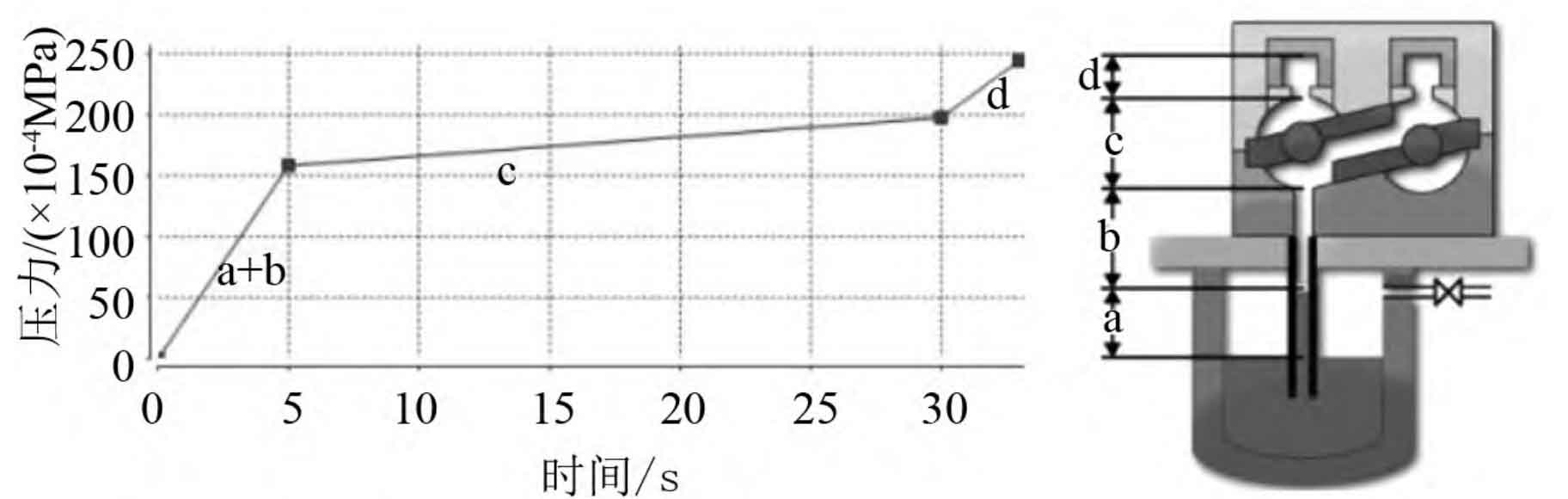

(1) Optimization of casting pressure curve of cylinder head. The low pressure casting curve generally passes through five stages: liquid raising, mold filling, pressurization, pressure maintaining, and exhaust cooling. The casting adopts self-feeding and non-pressurized low pressure casting method, as shown in Figure 2. Stage a+b is the filling process of the riser and gating system, stage c is the filling process of the cylinder head casting cavity, and stage d is the riser filling process. This method does not feed through the aluminum liquid in the crucible. The inner runner is solidified first and the feeding channel is cut off, The riser arranged above forms a top-down feeding mode for the cylinder head casting, and the increase of pouring temperature can ensure the feeding capacity of the riser.

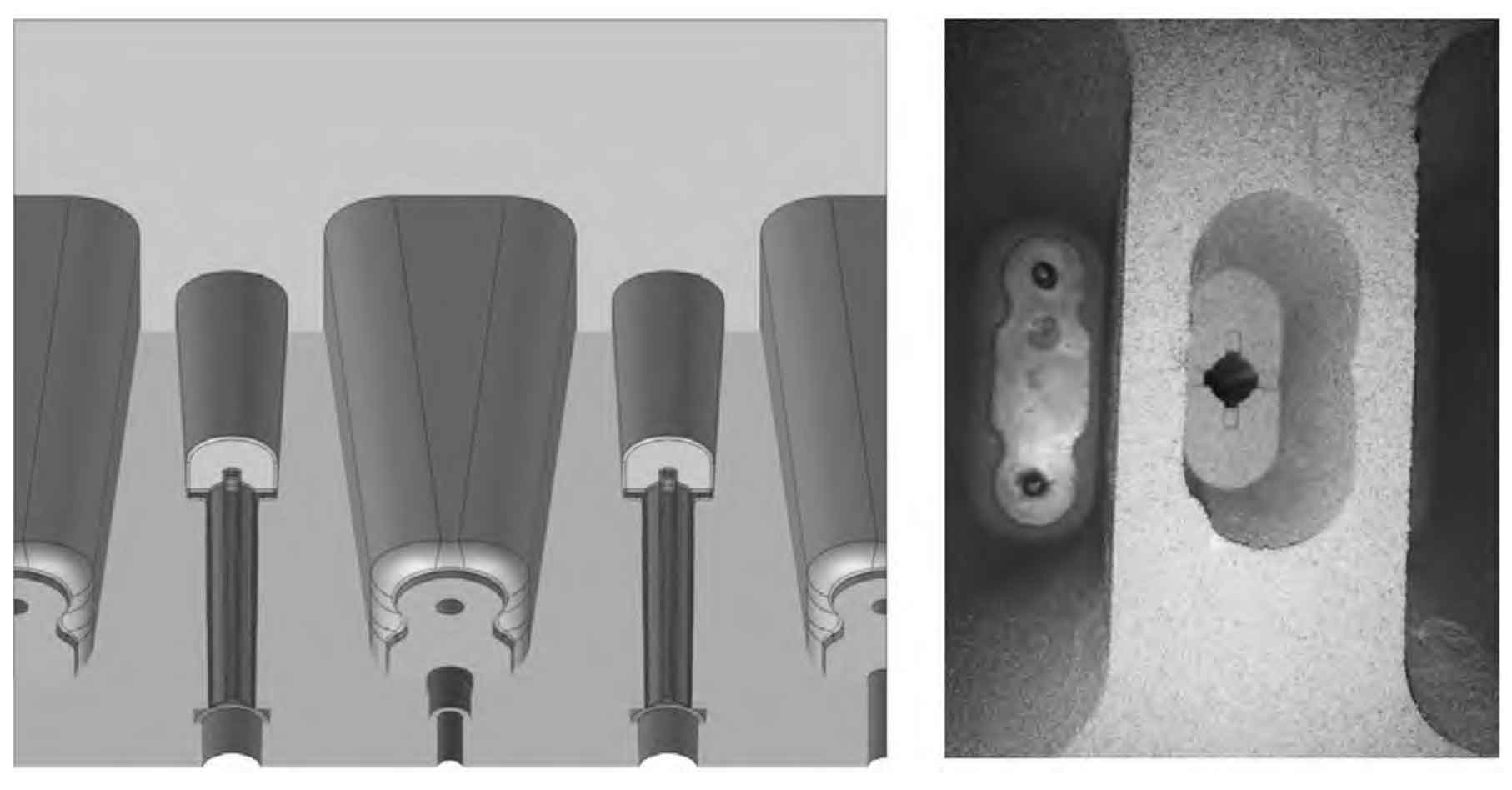

(2) Core preparation based on 3D printing. The gas evolution of the sand core produced by traditional manual resin sand molding is about 11~15 mL/g. In order to reduce the air hole defects caused by manual resin sand molding, 3D printing technology is selected for the overall core printing preparation of the water cavity and air channel cores. On the basis of ensuring the strength of the sand core, the gas evolution of the sand core is reduced. The gas evolution of the molding material is tested by the gas evolution tester, and the detection values are less than 7 mL/g, which not only improves the production efficiency, but also reduces the gas immersion of aluminum liquid, It reduces the generation of pore defects from the root.

(3) The exhaust channel of sand core is set. Although the preparation of sand core has been improved from the source of gas generation, the resin combustion in the sand core will still form gas. Therefore, the most effective way to effectively control the formation of air holes is to design a reasonable exhaust channel. By optimizing the structure of the candle core in the injector hole, add an exhaust channel. As shown in Figure 3, add 4 exhaust channels in the upper model to effectively guide the gas discharge.