To ensure high-quality castings and minimize defects, it is crucial to implement effective quality assurance practices throughout the casting process. Here are some best practices for detecting and preventing casting defects:

- Process Control and Monitoring:

- Implement robust process control measures to monitor key parameters such as temperature, pressure, and time during various stages of the casting process.

- Utilize advanced technologies like sensors, data acquisition systems, and real-time monitoring to ensure process variables are within specified limits.

- Regularly calibrate and maintain equipment to ensure accurate measurements and control.

- Visual Inspection:

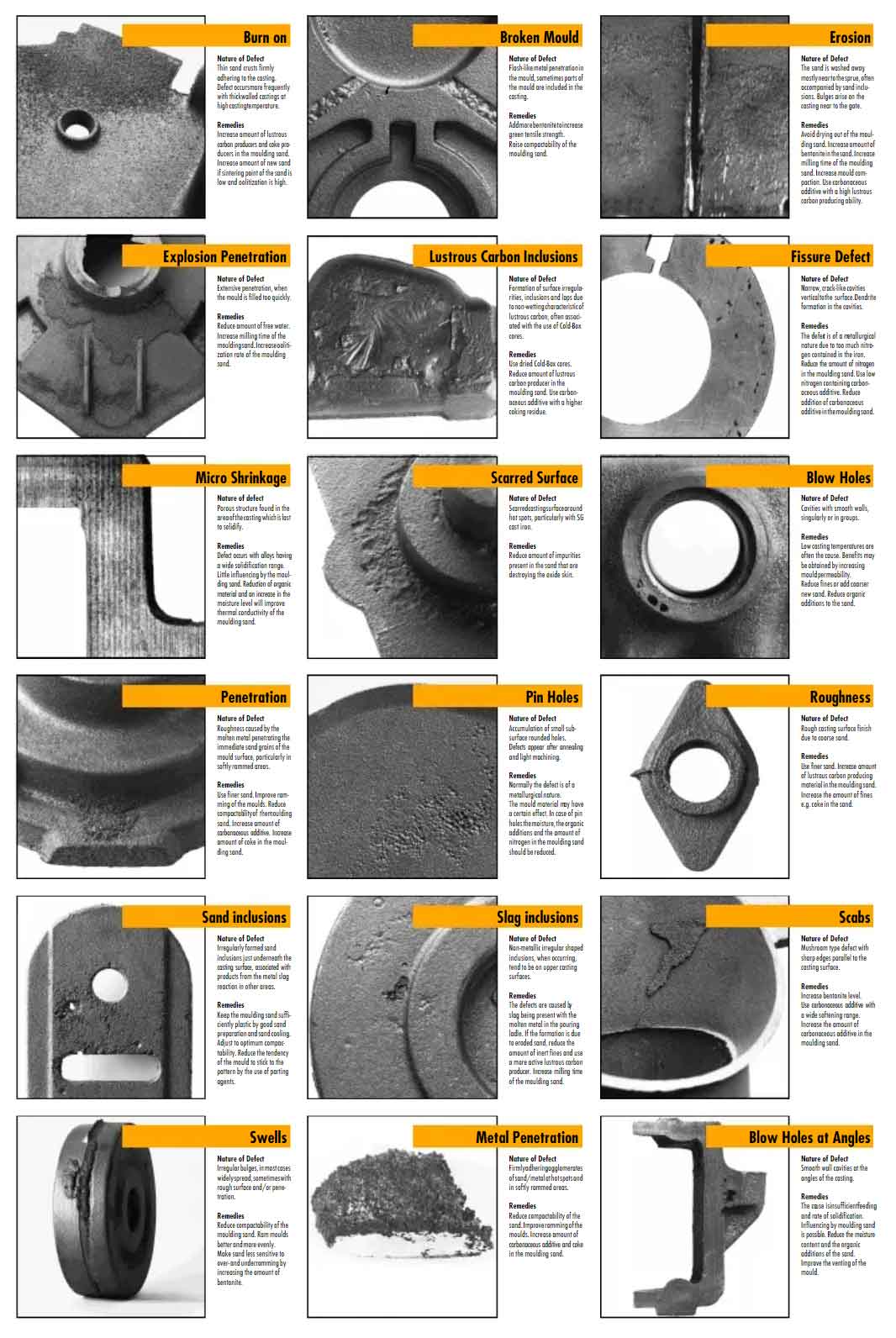

- Conduct thorough visual inspections of castings at different stages, including pre-casting, post-casting, and after cleaning processes.

- Train operators and inspectors to identify common defects and abnormalities in surface finish, dimensions, and overall quality.

- Non-Destructive Testing (NDT):

- Utilize NDT techniques such as radiography, ultrasonic testing, magnetic particle testing, and dye penetrant testing to identify internal defects and discontinuities without damaging the casting.

- Perform NDT on critical or high-value castings to ensure their integrity and reliability.

- Metallographic Examination:

- Conduct metallographic examinations by analyzing microstructures and grain sizes of castings to identify issues such as improper solidification, segregation, or material defects.

- Use appropriate sample preparation techniques and microscopy tools to examine the internal structure of castings.

- Quality Control Documentation:

- Maintain comprehensive documentation of process parameters, inspection records, and test results to track quality trends, identify recurring issues, and enable traceability.

- Establish well-documented standard operating procedures (SOPs) to ensure consistent practices and facilitate training of personnel.

- Quality Audits and Continuous Improvement:

- Conduct regular internal audits and quality assessments to identify potential areas for improvement.

- Implement corrective and preventive actions based on root cause analysis of defects and customer feedback.

- Foster a culture of continuous improvement by encouraging feedback from operators, inspectors, and other stakeholders involved in the casting process.

- Training and Skill Development:

- Provide comprehensive training programs for operators, inspectors, and personnel involved in the casting process to enhance their understanding of defect detection and prevention.

- Promote cross-functional training and knowledge sharing to improve overall process understanding and problem-solving capabilities.

- Collaboration with Suppliers:

- Work closely with material suppliers, mold makers, and other stakeholders to ensure the quality and consistency of raw materials, mold components, and auxiliary materials.

- Communicate and collaborate on quality standards, specifications, and any specific requirements to minimize the risk of defects.

By implementing these best practices for quality assurance, manufacturers can effectively detect and prevent casting defects, ensuring the production of high-quality castings that meet the desired specifications and customer expectations.