The selection of parting surface is directly related to the dimensional accuracy, production cost and efficiency of nodular cast iron. The selection of parting surface should be combined with the selection of casting position, and the two should be coordinated, which is conducive to simplify the casting process, reduce the production cost and improve the quality of nodular cast iron. The following principles shall be followed when determining the parting surface:

(1) Try to make most or all of the nodular cast iron in the same half mold. If it cannot be fully realized, ensure that the machined surface of nodular cast iron is placed in the same box. The parting surface is the surface on which the nodular cast iron is taken out, which is prone to misalignment defects, thus affecting the accuracy of nodular cast iron. Therefore, when selecting the parting surface, try to avoid the parts with strict size requirements on nodular cast iron being crossed by the parting surface.

(2) The less the number of parting surfaces, the better, and the plane is preferred. Plane parting can simplify the molding process and ensure the accuracy of nodular cast iron more easily.

(3) In order to reduce the difficulty of mold lifting, try to make the parting surface located at the largest section of nodular cast iron. For high nodular cast iron, it should be avoided that the nodular cast iron is too high in one box.

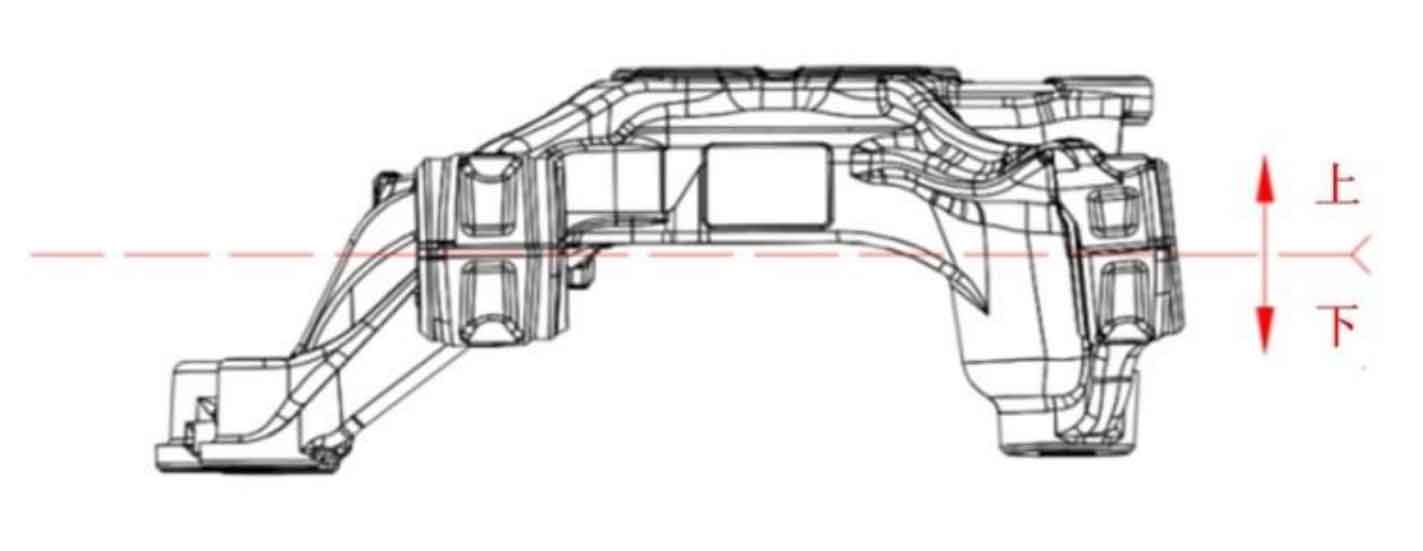

(4) Convenient for core removal, box closing and subsequent cleaning. At the same time, considering that the casting position of nodular cast iron of the hub support is selected according to the above principles, the parting surface is selected at the cross section of the sand core hole to facilitate the cleaning of the lower core. Moreover, due to the complex and irregular structure of the hub support, the use of plane parting is not conducive to ensuring the accuracy of nodular cast iron, but will increase the difficulty of cleaning after nodular cast iron. Therefore, the curved surface parting method is adopted, and the parting surface is shown in the figure.