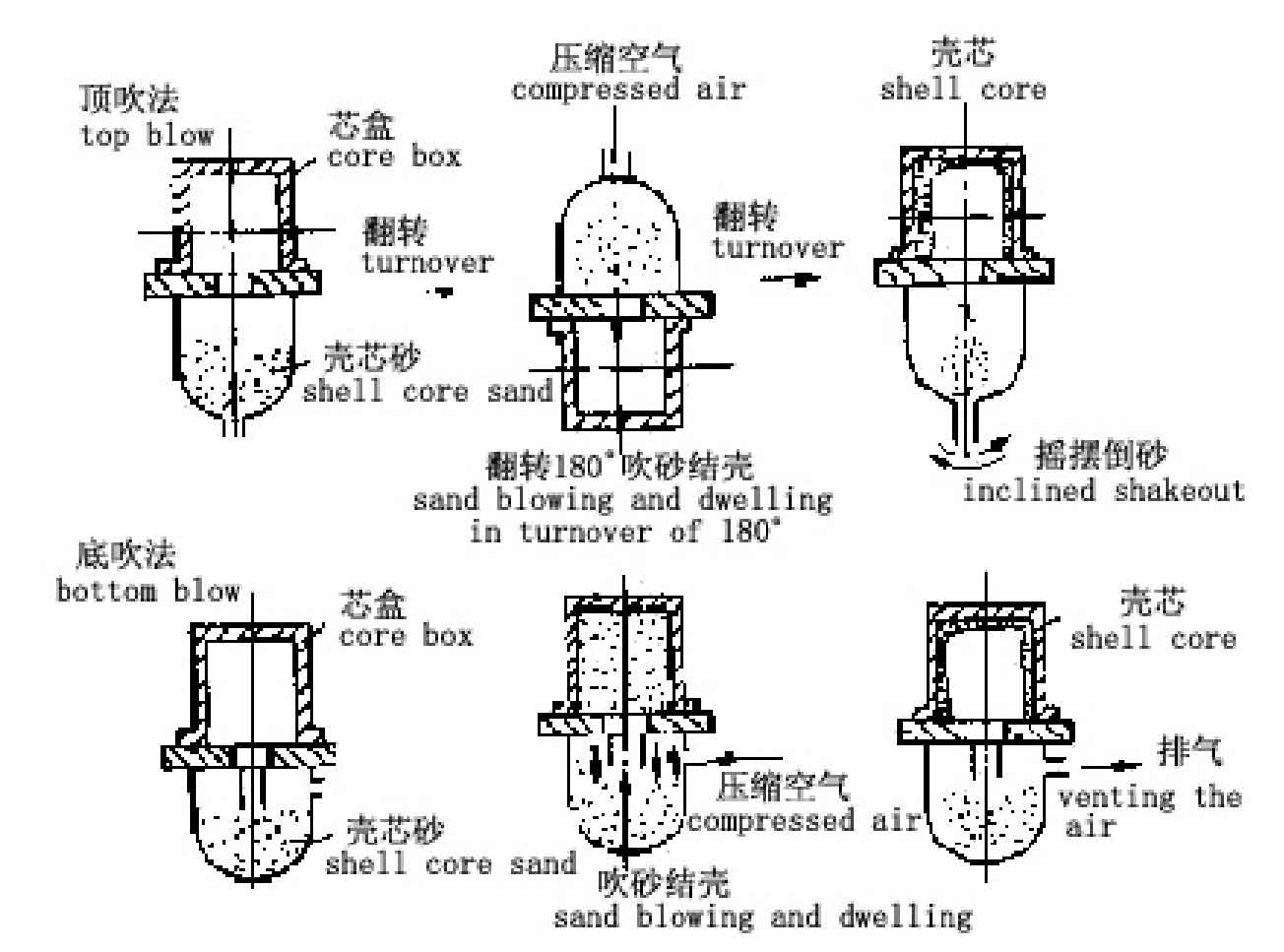

In 1940, Johannes Croning, a German engineer, invented the thermal method for manufacturing shell mold, which is called “C” method or “shell method”. After 1944, it was used to manufacture the shell mold (core) of castings and officially applied for a patent. Since then, the technology of making mold (core) with organic chemical binder has been applied to the foundry industry. In the late 1940s, the shell mold method was officially used to produce castings in the United States and West Germany. This method can be used not only for modeling, but also for manufacturing shell core. In this method, phenolic resin is used as binder, and the prepared mold (core) sand is called coated sand. This kind of sand is still as loose as dry sand. There are two methods of shell making: tipping method and sand blowing method (see Figure).

The advantages of shell molding and core making are that the mixed coated sand can be stored for a long time (more than three months); Without tamping sand, the mold and core with accurate size can be obtained; The mould and core have high strength, light weight and easy handling; Good air permeability, fine raw sand can be used to get a smooth casting surface; No sandbox required; The consumption of coated sand is small; The mold and core can be stored for a long time. Although phenolic resin coated sand is expensive and consumes high energy in molding and core making, it is still used in industries requiring smooth surface and high dimensional accuracy of castings. Generally, the shell mold is mostly used in the production of hydraulic parts, camshaft, crankshaft, corrosion-resistant pump parts, crawler shoes and other steel castings, and the shell core is mostly used in some castings such as automobile, tractor and hydraulic valve body.

Although shell casting was invented in Germany, it is widely used in the United States and other countries. As early as the late 1940s, the United States built a highly mechanized and automated shell mold casting workshop. In the early 1950s, Ford Motor Company established a large shell mold workshop with a daily output of 150t castings. In the late 1950s, General Motors Company of the United States successively established large shell mold workshops with a daily output of more than 100t. The agricultural tractor with an annual output of 500000 t was put into operation in the late 1960s John deerey of combine harvester castings and the shell mold (core) method of the foundry of general casting company and Walker branch expanded in the mid-1970s also account for 25% of the whole core making. Japan is a country where shell casting is widely used. In the early 1970s, Japan had more than 4000 shell (core) machines. Despite the emergence of other new processes, the application of shell casting and the amount of shell sand are still increasing. The foundry affiliated to Komatsu company, which is supporting construction machinery, uses shell mold (core) to produce all the cores of castings. In the factory with an annual output of 40000 tons of automobile castings of Asama Technology Research Industry Co., Ltd., the shell core accounts for 99% and the cold core box accounts for 1%. Hitachi metal Kyushu factory and Kyoto production Institute of automatic vehicles all produce castings with an annual output of 60000 tons of automobile chassis and motorcycle castings mainly based on shell and core. According to the Symposium on shell mold casting technology between Japan qunrong chemical company and China’s first automobile manufacturer in May 1980, Japan has 500 shell mold foundries, more than 26000 shell mold (core) machines, and the annual consumption of phenolic resin is 40000 tons. By 1982, Japan’s shell molding sand accounted for more than 37% of all kinds of molding sand.

The former Soviet Union is also a country where shell casting is widely used. In the mass-produced automobile, tractor and engine manufacturing industry, about 80-90% of the sand core is shell core. As early as the mid-1950s, shell production lines were built in Kiev motorcycle factory and Gorky automobile factory of the Soviet Union; In the production of 250000 diesel engines and 150000 truck castings in Kama River truck factory designed by the United States in the 1970s, the shell mold accounted for a considerable proportion in core making. In recent years, the newly designed and put into operation Tomsk Siberian motor plant adopts shell sand metal mold assembly line to produce 4a112, 4a132 and 4a180 motor bases. As the factory has obtained successful experience in producing motor base with shell sand metal mold, this new achievement will be popularized and applied in ferrakimir motor factory. It creates a new way for motor castings to adopt shell sand metal mold process.

The application of shell casting in Germany is also quite mature, accounting for a large proportion in core making. In 1986, the former Federal Republic of Germany conducted an investigation on the practical application of molding and core making methods, which showed that the shell type accounted for 18%, the cold core box method accounted for 30%, and the hot core box method accounted for 26%. Among the automatic factories with a monthly output of more than 1000 tons, shell core making accounts for about 21%. The former Georg Fisher malleable iron factory in Federal Germany was the first modern foundry in Europe to specially produce automobile castings in the early 1960s. The monthly output of castings is 6-7000 tons, of which 60% applies shell mold method.

Gisag Yuri Gagarin factory of the former Democratic Republic of Germany has built a new crankshaft and camshaft shell mold casting workshop. In a very short time, all crankshaft and camshaft castings for 1.1L and 1.3L four stroke automobile engines are produced by shell mold method, and its quality can be comparable to that of similar products of other companies.

In addition, in the automotive and construction machinery industries in Britain and France, the shell mold (core) method also accounts for about 20-30% of the production of mass castings.