Abstract

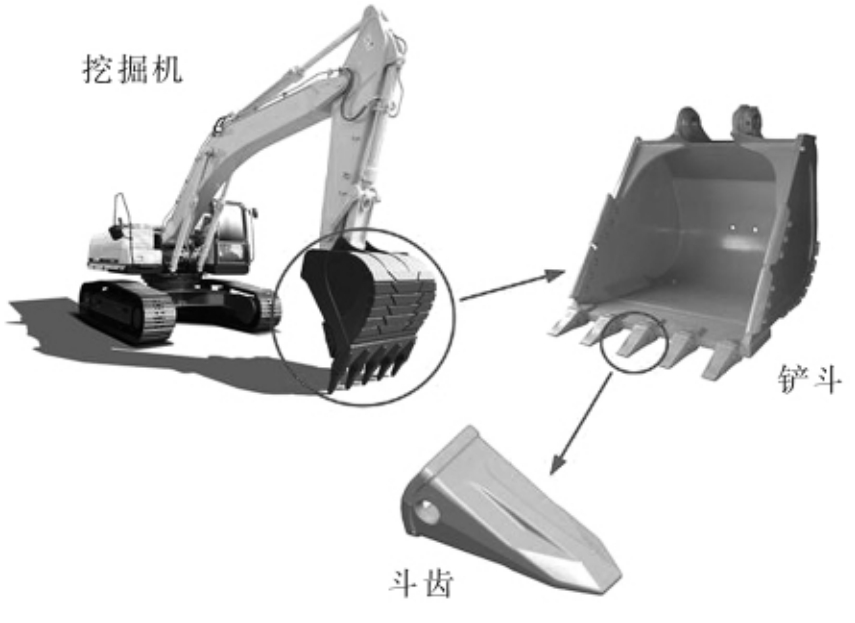

Bucket teeth are crucial components in excavators, enduring significant impacts during the excavation process. Ensuring their structural integrity and performance under complex loading conditions is vital. This article delves into a comprehensive dynamics analysis of bucket teeth for excavators, leveraging reverse engineering techniques. It presents a detailed methodology encompassing reverse modeling, finite element analysis (FEA), modal analysis, and transient dynamic analysis. The objective is to ascertain the inherent characteristics and dynamic responses of bucket teeth under impact loads, thereby validating their structural strength. The findings provide a novel approach for the design and analysis of excavator bucket teeth, facilitating cost reduction, efficiency enhancement, and shortened development cycles.

1. Introduction

Bucket teeth, as integral parts of excavators, play a pivotal role in the excavation process. They are subjected to intense impacts and abrasive forces, leading to potential wear, deformation, and cracking. Traditional design methods often rely on empirical data and iterative testing, which can be time-consuming and costly. In recent years, reverse engineering techniques have emerged as a promising alternative, enabling the accurate recreation of physical objects into digital models.

This article explores the application of reverse engineering in the dynamics analysis of excavator bucket teeth. By utilizing three-dimensional (3D) scanning, software for data preprocessing and modeling, and advanced finite element analysis tools, the study aims to gain insights into the mechanical behavior of bucket teeth under various loading conditions. The results obtained provide a solid foundation for optimizing the design of bucket teeth, enhancing their durability, and reducing maintenance costs.

2. Literature Review

Previous research on bucket teeth has primarily focused on improving their durability and wear resistance. Various materials and coating technologies have been investigated to enhance the hardness and abrasive resistance of bucket teeth. Additionally, several studies have employed finite element analysis to investigate the stress and strain distributions within bucket teeth under different loading scenarios.

However, most of these studies have relied on existing CAD models for their analyses. In contrast, reverse engineering offers the capability to create digital models directly from physical objects, without the need for original design data. This approach is particularly useful when dealing with legacy equipment or components where the original design information is unavailable.

3. Methodology

3.1 Reverse Modeling of Bucket Teeth

The first step in the methodology involves the reverse modeling of bucket teeth. This process begins with the acquisition of 3D point cloud data using a high-resolution 3D scanner. The scanner captures the surface geometry of the bucket teeth in a dense cloud of points.

Once the point cloud data is acquired, it undergoes preprocessing using software such as Geomagic Studio. This includes the removal of noise points, simplification of data, and alignment of the point cloud to ensure accuracy. The preprocessed data is then used to create a polygonal mesh, which is further refined to produce a smooth and accurate surface model.

The refined mesh is exported in a suitable format (e.g., STL) and imported into a CAD software (e.g., UG) for reverse modeling. In UG, the mesh is used as a reference to construct surfaces and solids that represent the bucket teeth. The modeling process involves the use of various curve and surface construction techniques, such as section curves, intersection curves, bridging curves, trimming curves, and various surface operations.

Once the initial model is created, it can be mirrored to generate the complete bucket tooth assembly. This approach allows for the accurate recreation of the bucket teeth based on their physical dimensions, without the need for original design data.

3.2 Modal Analysis of Bucket Teeth

Modal analysis is a crucial step in understanding the dynamic behavior of bucket teeth. It involves determining the natural frequencies and mode shapes of the structure, which are essential for predicting its response to dynamic loads.

The modal analysis is performed using finite element analysis software such as ANSYS. The bucket teeth model created during the reverse modeling process is imported into ANSYS, and material properties (e.g., elastic modulus, Poisson’s ratio, density) are assigned.

The mesh generation is a vital pre-processing step in the modal analysis, where the bucket teeth model is divided into smaller, more manageable elements. A finer mesh is typically used in areas of higher stress concentration, such as the tooth tip, to ensure accuracy in the results.

Boundary conditions are then applied to the model to simulate the actual constraints during operation. In the case of bucket teeth, the pin holes are usually constrained to prevent any movement in the X, Y, and Z directions, simulating the fixed connection with the tooth holder.

Once the pre-processing steps are completed, the modal analysis is conducted to determine the natural frequencies and mode shapes of the bucket teeth. The natural frequencies are critical as they help to identify potential resonance issues, which could lead to premature failure of the structure.

The modal analysis results provide valuable insights into the dynamic behavior of the bucket teeth. The research, conducted by Xu Xilin and Wang Zhenqian, revealed the natural frequencies and corresponding amplitudes for the first ten modes of the bucket teeth. These results can be used to optimize the design and improve the durability of the bucket teeth by avoiding operational frequencies that could cause resonance.

In conclusion, modal analysis is a fundamental aspect of understanding the dynamic behavior of bucket teeth. By using finite element analysis software, such as ANSYS, and following a rigorous pre-processing procedure, including mesh generation and boundary condition application, accurate results can be obtained. These results are crucial for ensuring the reliability and performance of bucket teeth in various operational conditions.