(1) Effect of amplitude on hardness of gray cast iron

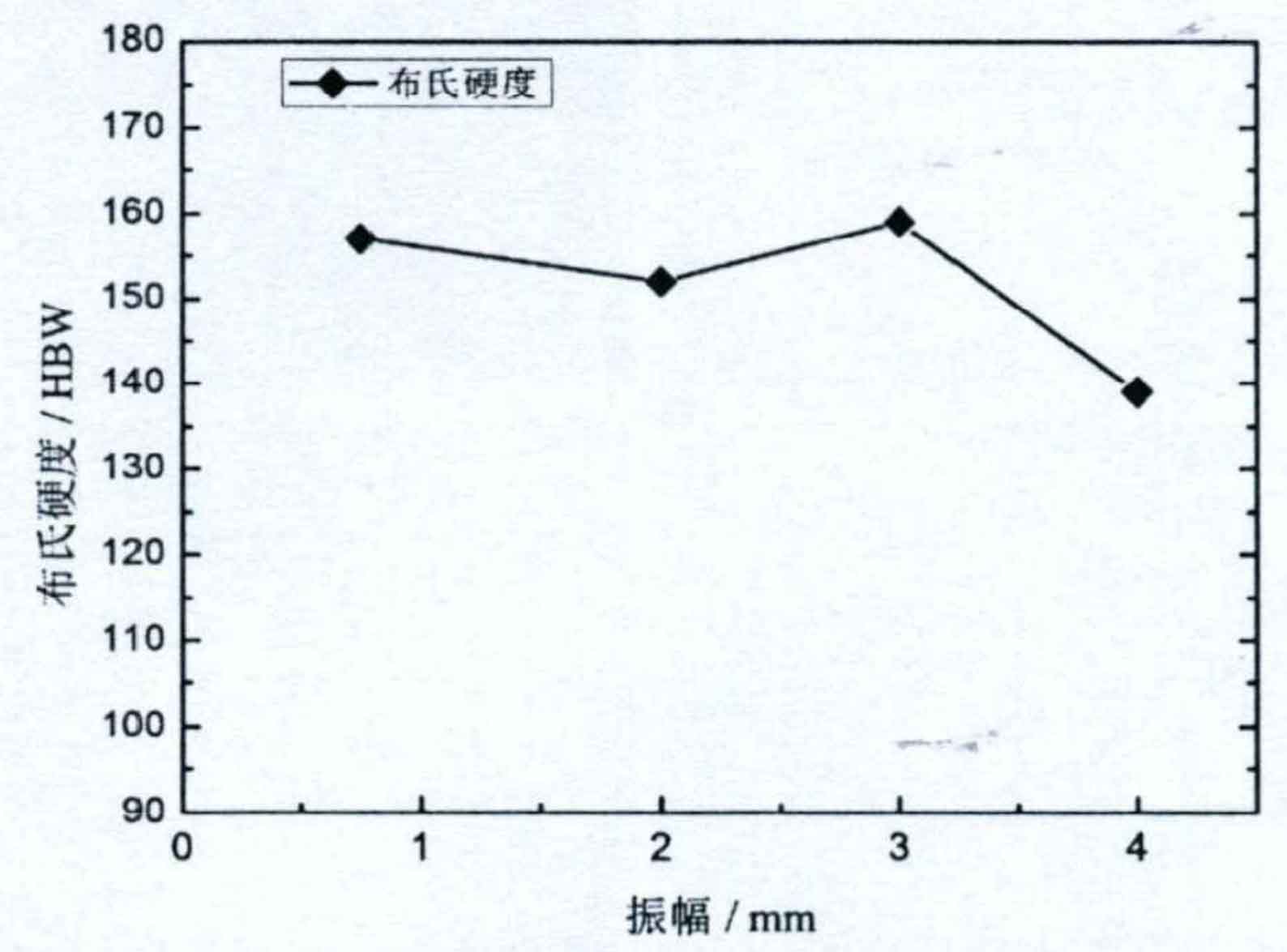

Figure 1 shows the change curve of Brinell hardness of gray cast iron with amplitude.

It can be seen from Figure 1 that with the increase of amplitude, the Brinell hardness of gray cast iron decreases first, then increases and then decreases. The Brinell hardness value of grey cast iron prepared at the amplitude of 4mm is small, while the Brinell hardness value of grey cast iron prepared at the amplitude of 3mm is the largest, but there is little difference between the Brinell hardness value of grey cast iron prepared at the amplitude of 0.75mm and 2mm.

Austenite is the product of primary crystallization of gray cast iron. At room temperature, the original framework structure of austenite is retained in the cast iron, which plays a strengthening role in the gray cast iron matrix. The change trend of Brinell hardness of gray cast iron with the increase of amplitude is mainly related to the austenite structure characteristics and pearlite transformation products in gray cast iron. Yuansen and other researchers believe that the Brinell hardness of gray cast iron is low due to the lack of framework structure of short and undeveloped equiaxed dendrite structure. Therefore, the Brinell hardness value of gray cast iron prepared at the amplitude of 4mm is low. However, in the gray cast iron prepared under the condition of low amplitude, the austenite dendrites show columnar dendrites with certain orientation or dendrites with developed endogenous growth and branching, so the hardness values of the alloy are similar.

(2) Effect on mechanical properties

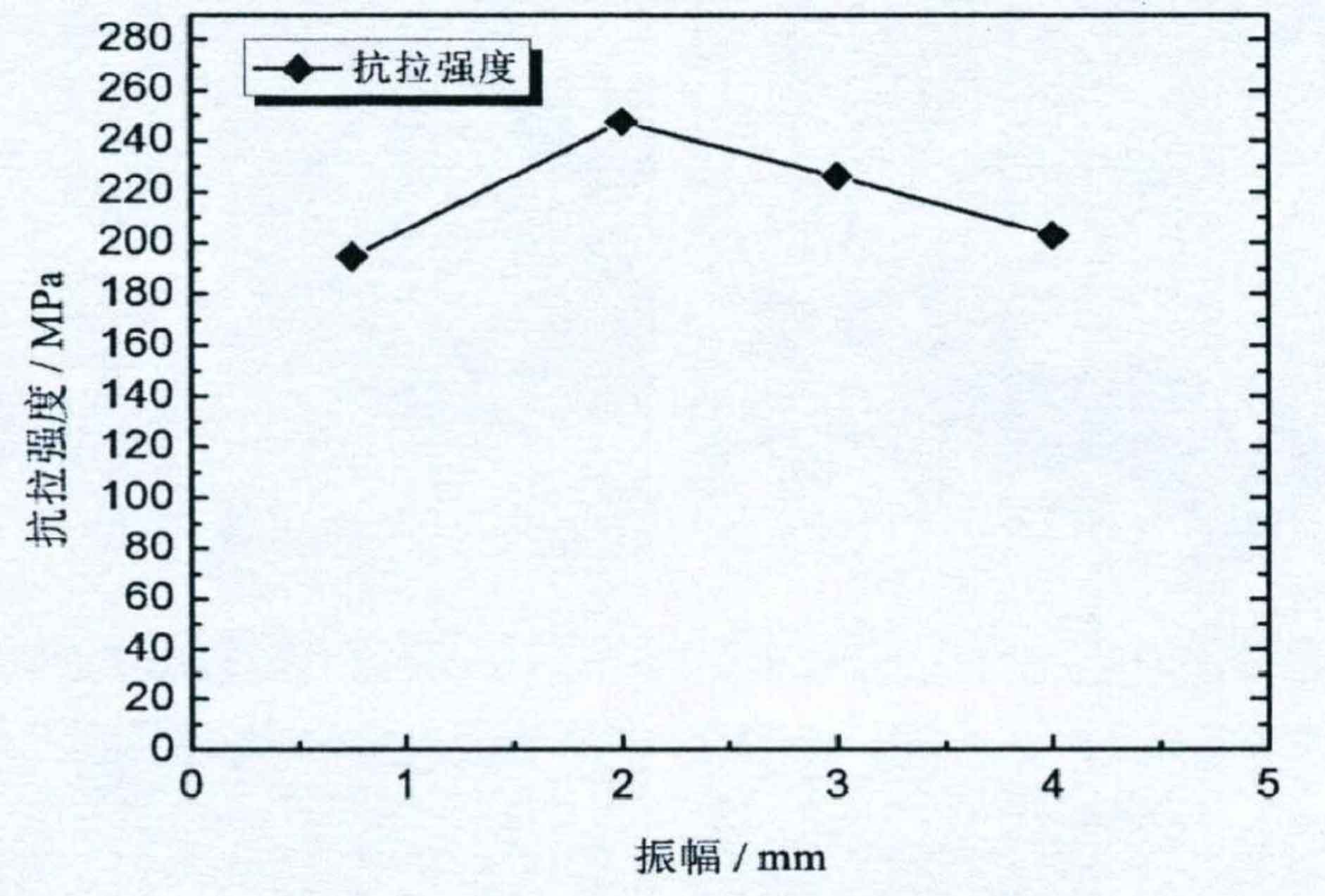

Fig. 2 shows the variation curve of mechanical properties of gray cast iron with amplitude. It can be seen from Fig. 2 that the tensile strength of grey cast iron increases first and then decreases with the increase of amplitude. The tensile strength of grey cast iron prepared with an amplitude of 2mm is the highest, with a value of 247.51mpa. The tensile strength of grey cast iron prepared with an amplitude of 0.75mm is the lowest, with a value of 194.61mm. Compared with that of grey cast iron prepared with an amplitude of 2mm, the tensile strength decreases by 21.37%.

In grey cast iron, the main factors affecting its properties are austenite dendrite and graphite in grey cast iron. It can be seen from the analysis that in the gray cast iron prepared with the amplitude of 0.75, 2 and 3mm, the austenite presents columnar crystals with certain orientation, or dendrites with developed endogenous growth and branching. When a certain external force is applied to the gray cast iron, if the direction of the principal stress is perpendicular to the primary principal axis of the columnar dendrites, The crack usually passes through the intersection of the secondary dendrite arms between the main axes. The primary dendrites have high spindle strength and are not easy to cut off. The junction of the end of the secondary branch arm is eutectic structure, which is easy to be torn, reducing the tensile strength of gray cast iron. When the principal stress is parallel to the primary crystal axis, because the primary crystal axis has a large bearing capacity, the crack is not easy to pass through the primary principal axis of dendrite. In this case, if you want to fracture the primary principal axis of dendrite, you must consume more energy. At this time, the tensile strength of gray cast iron is large. However, when the amplitude was 4mm, the austenite dendrite principal axis was short and thick, the secondary dendrite arm was undeveloped, and the network skeleton structure was not formed. When gray cast iron is subjected to tensile action, the crack propagates in the eutectic structure, and the anti load effect of austenite dendrite itself is relatively small, so its tensile strength is low.

In addition, the graphite in the gray cast iron is A-type flake graphite, which is equivalent to microcracks in the matrix structure and is easy to cause stress concentration at the sharp corners of the graphite. When the gray cast iron is stretched, the position of the graphite sheet is equivalent to a cavity, which has a large cutting effect on the matrix and reduces the performance of the gray cast iron to a certain extent.