The oxidation of materials will promote the crack propagation, so it is necessary to study the oxidation resistance of gray cast iron before studying the thermal fatigue resistance of materials. There are many factors affecting the oxidation resistance of materials, such as microstructure, grain size, trace elements and so on. In gray cast iron, the amount of graphite increases with the increase of carbon content. In the process of thermal cycle, the difference of thermal expansion system between graphite and matrix leads to the fact that the combination between them is not close, so that oxygen can penetrate into the matrix through the interface between graphite and matrix, which increases the contact area between matrix and oxygen and promotes matrix oxidation. Therefore, as mentioned above, with the increase of carbon content, the amount and size of graphite in gray cast iron increase, which promotes the oxidation of gray cast iron.

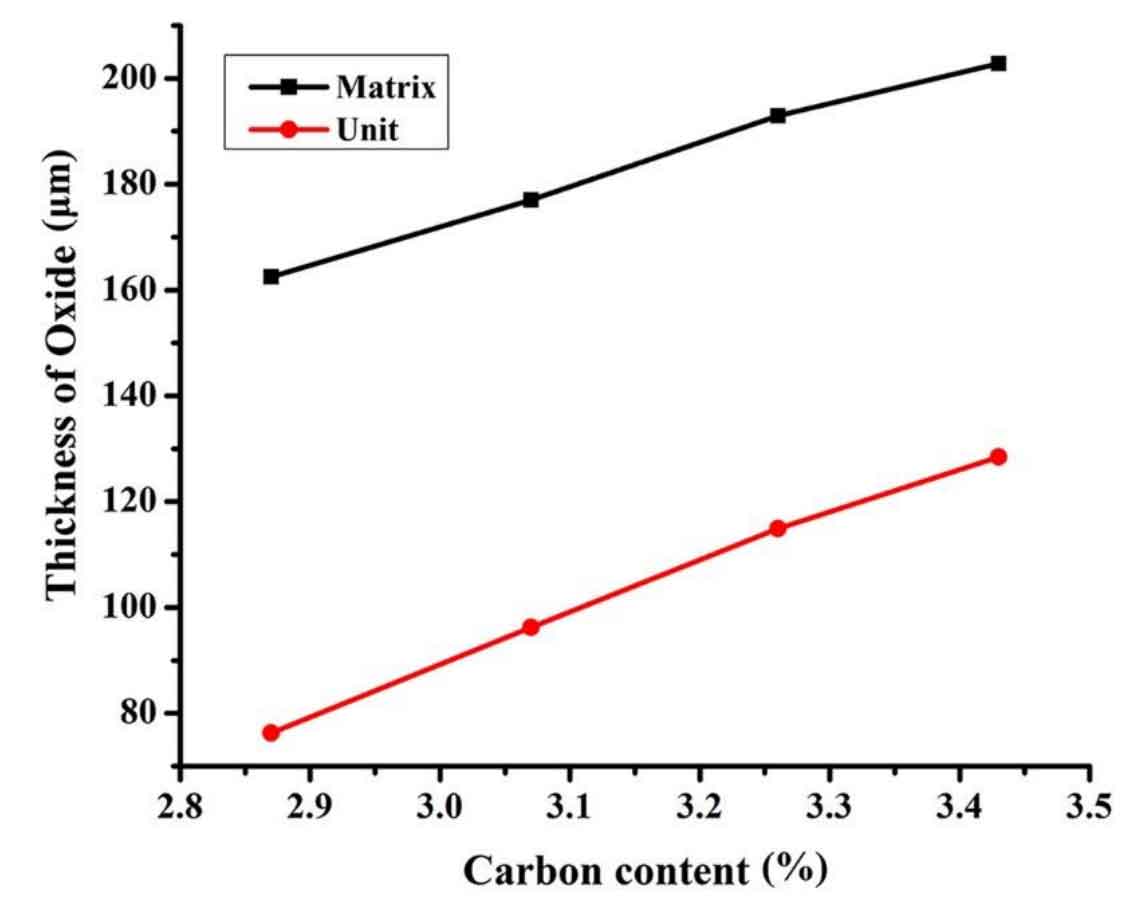

It can be seen from the figure that the thickness of the oxide layer of the matrix gradually increases with the increase of carbon content; On the whole, the antioxidant capacity of the unit body is better than that of the matrix, but the oxide skin thickness also increases with the increase of carbon content. This is because the graphite is completely dissolved in the process of laser melting, and the grains are refined in the process of chilling solidification.

Therefore, compared with the matrix, the unit structure is denser, the contact surface with oxygen is narrow, and it is not easy to oxidize. With the increase of carbon content in the unit body, the oxide skin thickness also increases. The reasons can be considered from the following aspects:

First, in the process of thermal cycle, the unit body, as a hard phase, bears greater thermal stress; The increase of carbon content leads to the increase of unit hardness and makes the unit more brittle. It is easy to break under the action of thermal stress and increase the contact surface with oxygen.

Secondly, in the process of thermal cycle, cementite decomposes and a large amount of carbon segregation precipitates, which also leads to the increase of oxide layer thickness.