In this test, the control variable method is adopted, and the material handle thickness is set as 16mm, 31mm, 42mm and 68mm respectively under the condition that other parameters remain unchanged.

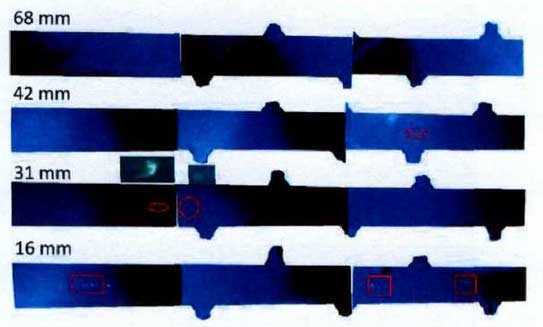

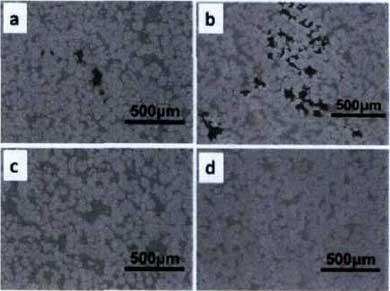

According to the sample preparation and detection method mentioned above, the semi-solid die-casting samples were sawed, polished, fluorescence detection metallographic observation and other methods to analyze the influence of material handle thickness on shrinkage cavity and porosity defects. The results are shown in Fig. 1, and Fig. 2 shows the metallographic photos of typical positions under 68 mm and 16 mm shank thickness.

It can be seen from Fig. 1 that when the material handle is thin (16mm), there are obvious shrinkage defects in the bottom and upper part of the sample. Under the fluorescence, they are bright spots and aggregation spots respectively, and they are black holes in the metallographic photos (Fig. 1ab). When the thickness of the stock handle increases (31-42mm), the shrinkage and porosity defects are obviously improved. It can be seen from the fluorescence observation that when 31mm is compared with 16mm, the original large-area aggregation spots change into bright spots of small particles, and appear Compared with 31mm, the location of bright spots decreased further and almost disappeared, which also meant that shrinkage porosity was basically eliminated, and there were only very small shrinkage holes in some positions. When the handle thickness increases to 68mm, there are no bright spots or aggregation spots in the whole area of the sample under fluorescence observation, and the black holes completely disappear under microscopic observation (Fig. 2c, d), which means that the shrinkage cavity and porosity defect have completely disappeared. After actual production verification, when the stock handle thickness increases to 68mm, the product without shrinkage cavity and porosity defect can be produced stably Cylindrical sample.

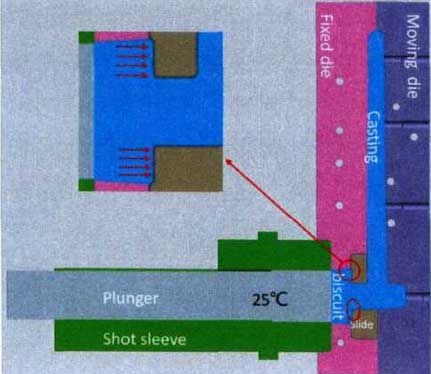

In the process of semi-solid die casting, the design of material handle is to complete feeding smoothly, which is equivalent to the riser part in gravity casting. In the process of die casting, it is necessary to ensure that the material handle area is the final solidification area of the whole casting, so as to meet the characteristics of “sequential solidification”. As shown in Fig. 3, due to the cooling water in the punch, and the temperature is too low (20-30 ° C), the tail area directly in contact with the punch will solidify as “hard shell”. The influence of the thickness of the material handle on the shrinkage cavity and porosity mainly includes the following two aspects:

(1) Influence on “sequential solidification”

In the process of die casting, because the tail of the material handle contacts the punch with very low temperature directly, the “hard shell” area will be formed at the tail of the material handle. When the handle thickness is low, the handle area completely changes into “hard shell” area, which breaks the “sequential solidification” principle, and the handle loses its original feeding function, resulting in shrinkage and porosity defects; when the handle thickness is large, “hard shell” area is only a small part of the handle, while the other parts of the handle are still semi-solid slurry shape, which still has the function of feeding and realizes smooth operation On the basis of the analysis, the shrinkage cavity and porosity gradually disappear with the increase of the thickness of the material handle.

(2) Indirect effect on pressure transfer

If the thickness of the handle is small, the “hard shell” part of the handle will directly contact the slide block of the die, resulting in the loss of pressure transmission in the process of pressurization. If the handle thickness increases to a certain value, the “hard shell” part of the handle will not directly contact the slide block of the die, and there is still semi-solid slurry between the “hard shell” and the slider, so the pressure loss is small and the feeding is more sufficient, thus eliminating the shrinkage cavity and porosity defect; through further reasoning, it can be concluded that when the handle thickness is too thick, there is a semi-solid between the “hard shell” and the slider Too much slurry will also lead to greater loss of pressure transmission, resulting in the re generation of shrinkage cavity. Therefore, the influence of handle thickness on shrinkage cavity and porosity is that shrinkage cavity gradually decreases and disappears with the increase of stock handle thickness. If the thickness of the handle is increased on this basis, the shrinkage cavity and porosity will appear again.