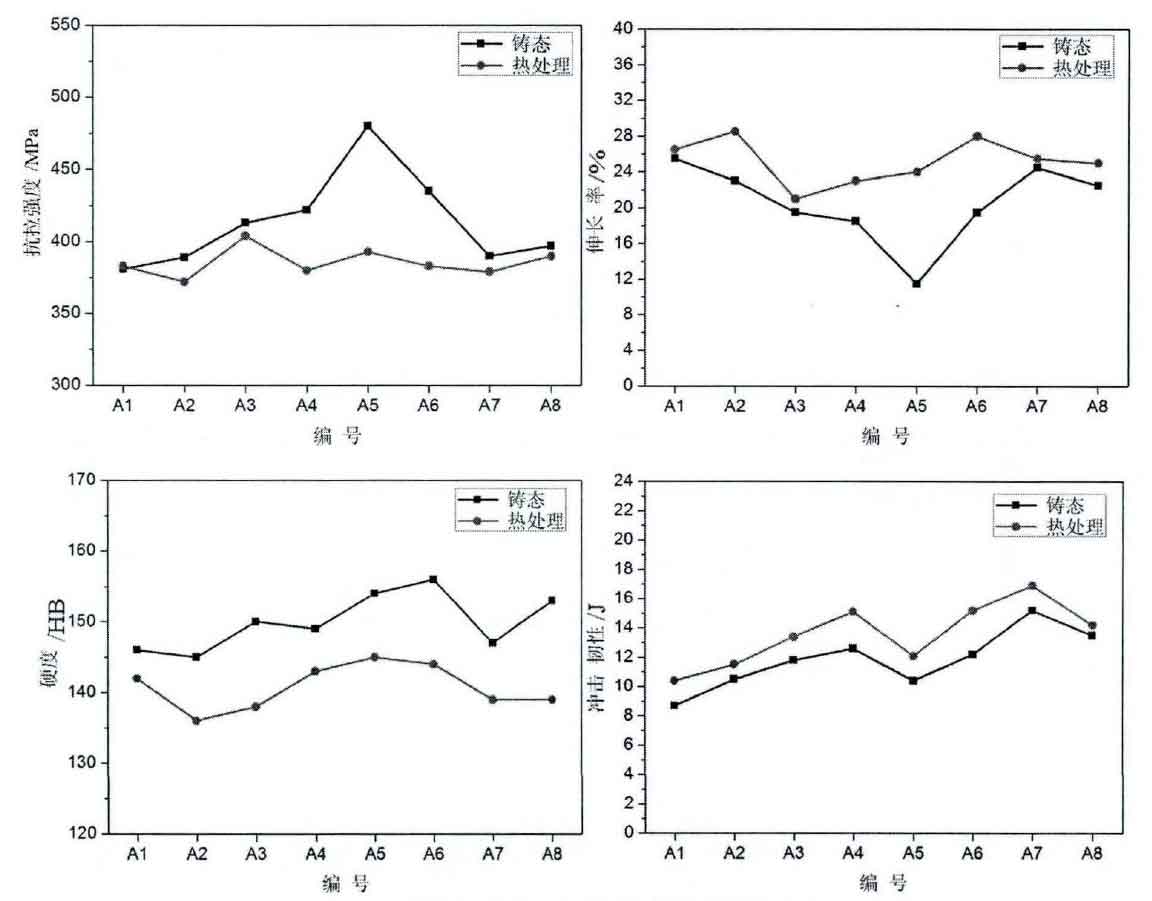

The figure shows the difference of mechanical properties of nodular cast iron of series a samples under as cast and heat treatment conditions.

It can be seen from the figure that the heat treatment of nodular cast iron can enhance the stability of mechanical properties, and the data will no longer fluctuate greatly. Through heat treatment, the tensile strength and hardness of nodular cast iron samples are reduced, so that the tensile strength is maintained at about 400MPa and the hardness is about 140. The elongation and low-temperature impact toughness of nodular cast iron samples increase, so that the elongation is more than 20%, and the low-temperature impact toughness is about 2J higher than that as cast, basically reaching the level of 12j.

It can be seen that the high and low temperature two-stage graphitization annealing process parameters formulated in the experiment are reasonable and the effect is obvious, which is suitable for the production of nodular cast iron for wind power accessories.