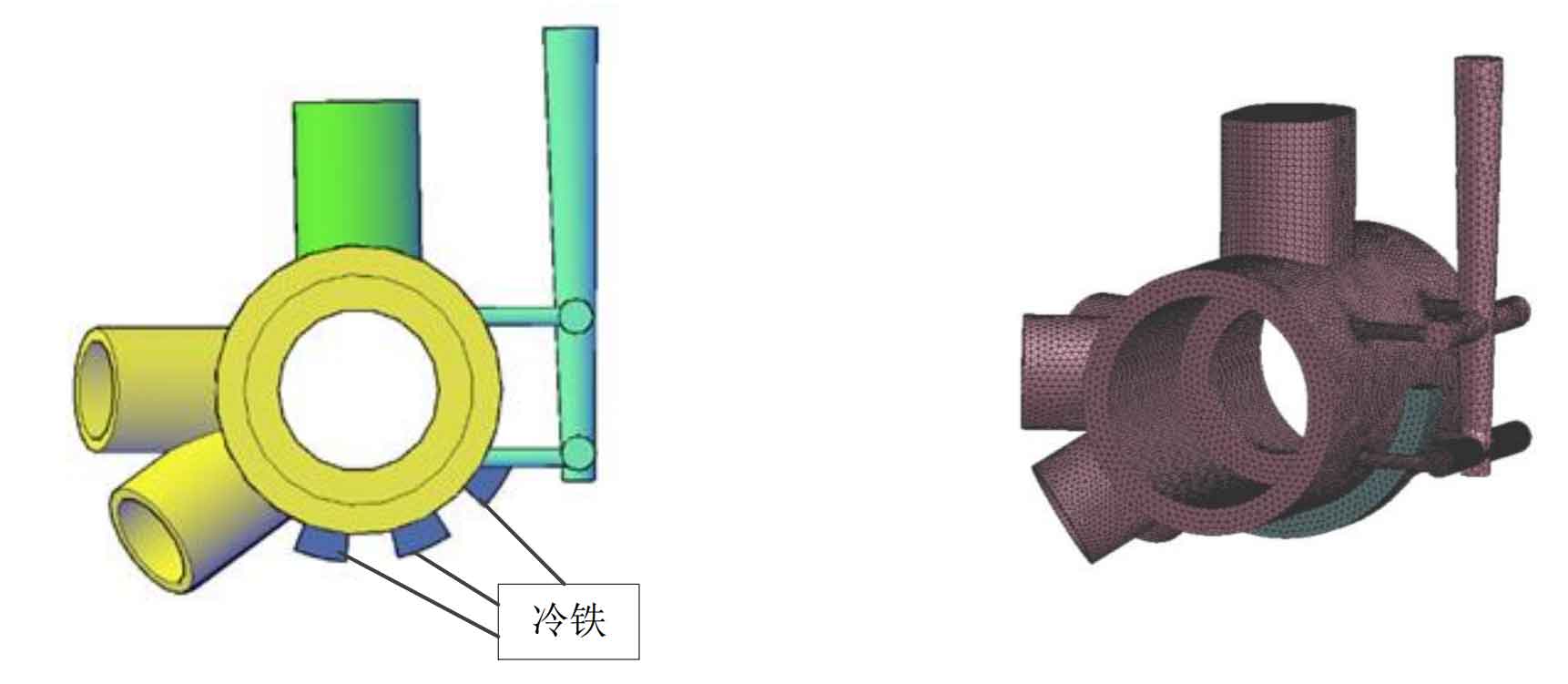

According to the previous casting simulation results, it is found that the process riser of the steel casting plant is too small, the overheating temperature at the bottom decreases slowly, and shrinkage porosity defects are easy to occur. Therefore, the casting process is further changed, and several cold irons are placed at the bottom of the cast steel joint for quenching and accelerating solidification. The riser height adopts 285mm high standard waist riser. The process setting and grid division are shown in Figure 1.

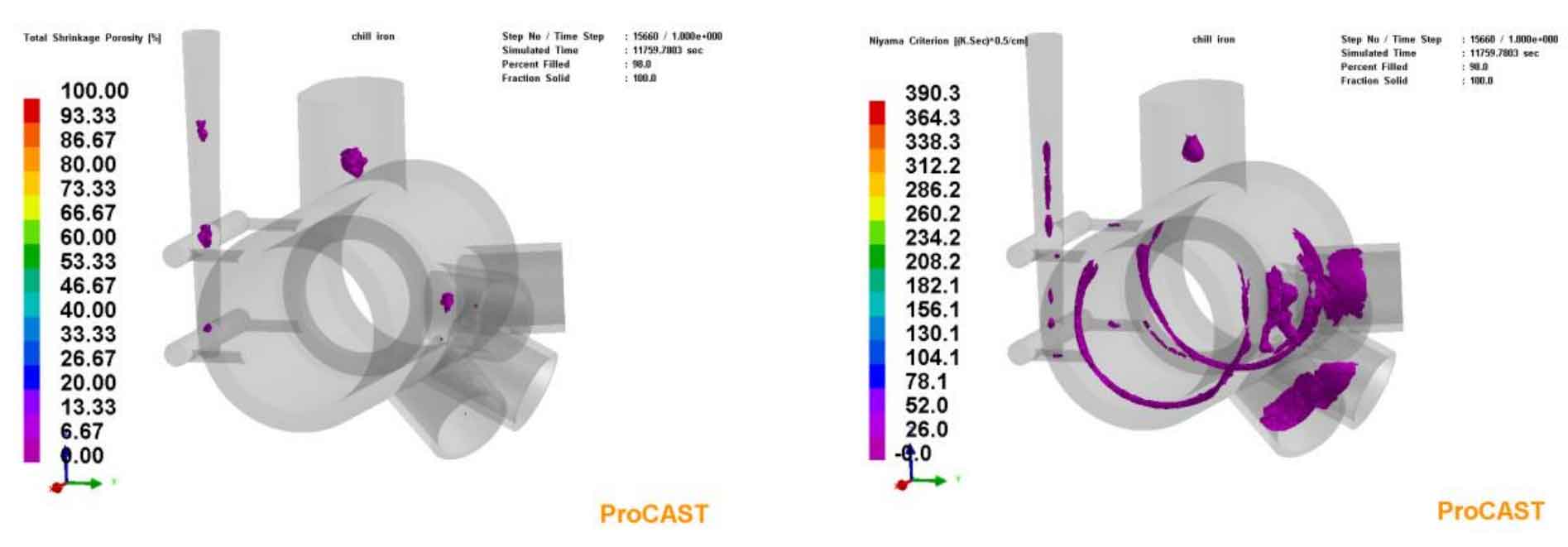

Similarly, the prediction diagram of casting shrinkage defects can be obtained, as shown in Figure 2. By improving the process, it can be found that the shrinkage defects of the riser have been greatly reduced, the shrinkage defects near the riser have been transferred to the inside of the riser, the shrinkage defects at the bottom have also been reduced, and the defects of the branch pipe still exist because no measures have been taken to change the temperature gradient of the branch pipe. The shrinkage defects under the stiffening rib plate have been well improved because the existence of cold iron accelerates the cooling of liquid steel at the bottom of the steel casting, but it will transfer some small shrinkage defects to other areas and can not completely eliminate the defects. Unless there are enough feeding channels to realize sequential solidification, the defects can be moved to the last solidified riser.