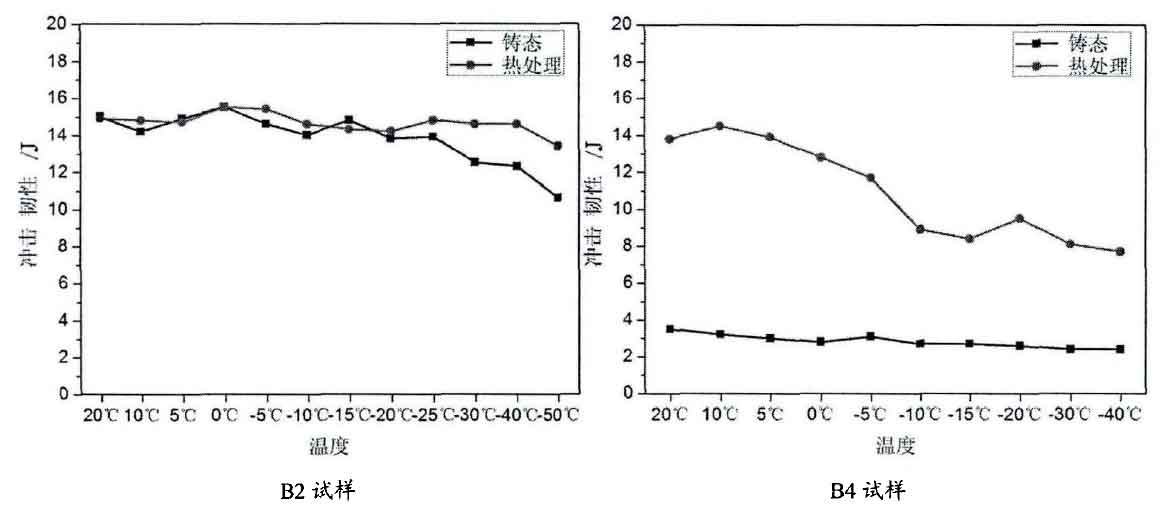

The figure shows the change law of impact toughness of nodular cast iron of B2 and B4 samples with temperature.

The impact toughness of B2 nodular cast iron in as cast state first decreases slowly with the decrease of temperature. When the temperature drops below – 25 ℃, the impact toughness begins to decrease greatly. When the temperature drops below – 30 ℃, the impact absorption energy drops below 12j. It can be concluded that the low-temperature brittleness transition temperature of B3 sample in as cast ductile iron is about – 25 ℃, and the impact toughness can meet the standard requirements of – 20 ℃, but it can not meet the requirements of – 40 ℃ in the standard. After heat treatment, the impact toughness of B2 sample also has a decreasing trend, but the decreasing speed is obviously slower. When the temperature drops to – 50 ℃, it still does not reach the low-temperature brittle transition temperature. At this time, the low-temperature impact toughness is about 13j, which can meet the requirements of 12j at – 40 ℃ in the standard. It can be seen that the low-temperature brittle transition temperature of nodular iron can be reduced by high-temperature and low-temperature two-stage graphitization annealing, so as to improve the low-temperature impact toughness.

Although the impact toughness of B4 nodular cast iron also decreases with the decrease of temperature, the change law is obviously different from that of B4 nodular cast iron. Because the impact toughness of B4 in as cast ductile iron is about 3-4j, and the brittleness has been great, although the decrease of temperature also reduces the impact toughness, the space for reduction is very small, and it is not affected by temperature. After heat treatment, the impact toughness of B4 is greatly improved and can reach 14J at room temperature. When the impact temperature drops below 12j, the toughness begins to drop rapidly. When the temperature drops to – 40 ° C, the impact toughness can only reach the standard level, which can not meet the requirements of the standard.

The obvious difference between B2 and B4 is mainly due to the addition of tin, copper and 0.006% bismuth. 0.5% copper can increase the low-temperature brittleness transition temperature of ductile iron to 0 ℃. The effect is very obvious. With the decrease of temperature, the impact toughness decreases rapidly. It can also be seen that the low-temperature ductile brittle transition temperature of nodular cast iron is not the only one, and the difference of microstructure will make it very different. Therefore, the influence of temperature on the impact toughness of the sample is also different.