The microstructure characteristics of gray cast iron determine its mechanical properties. For the microstructure of gray cast iron, the finer the graphite is bent, the higher the content of pearlite and the finer the lamellar spacing of pearlite, the more high-strength gray cast iron can be obtained.

We hope to increase the amount of modifier to affect the microstructure of gray cast iron, so as to improve its mechanical properties. It is very common to improve the mechanical properties of gray cast iron by adding modifier. This section studies the effect of the addition of modifier and the content of modifier on the mechanical properties.

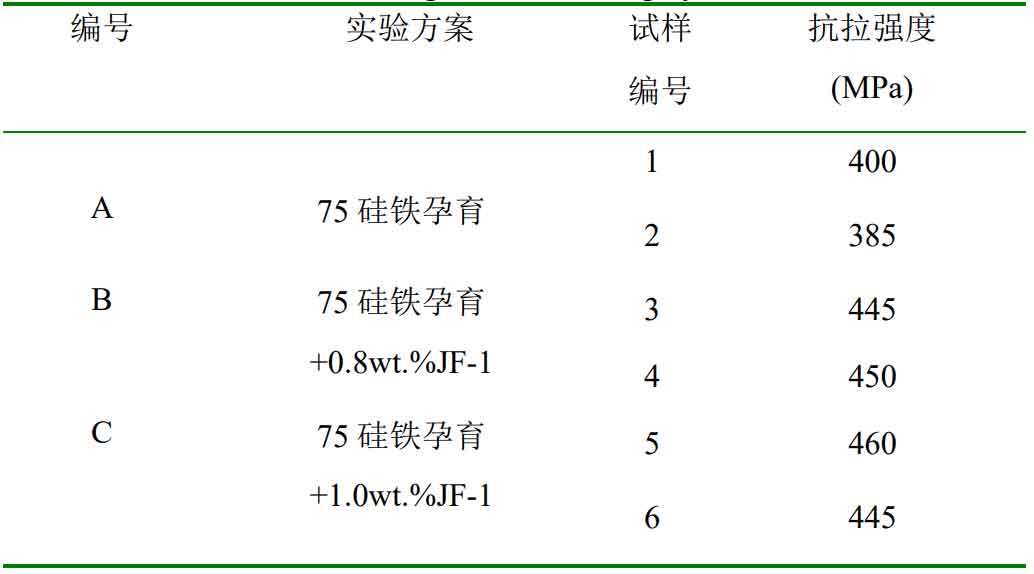

1. Effect of modifier content on tensile strength of high strength gray cast iron

Table 1 shows the tensile strength test results of experimental gray cast iron. By comparing the tensile strength of gray cast iron, it can be seen that the tensile strength increases by 50-60mpa with the addition of modifier. The analysis shows that after adding the modifier, the graphite structure is finer, bent, distributed more evenly, the spacing between the layers of matrix pearlite structure is smaller, and the network frame structure of primary austenite is more complex, so the tensile strength of gray cast iron is greatly improved; Moreover, the more the modifier is added, the finer and curved graphite, the smaller the pearlite sheet spacing, the more complex the framework structure of primary austenite network, the smaller the size and number of eutectic clusters. These structural characteristics improve the tensile strength.

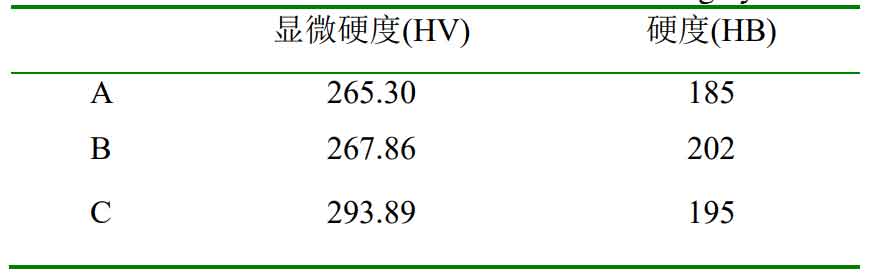

2. Effect of modifier addition on hardness of high strength gray cast iron

Table 2 shows the hardness test results of experimental gray cast iron. Comparing the Brinell hardness of three kinds of experimental gray cast iron, the difference is not too large. Comparing the microhardness of the matrix, the microhardness of the matrix of sample C is obviously higher, which corresponds to the minimum pearlite sheet spacing of sample C in the analysis. From the analysis of the influence of the amount of modifier on the microstructure of the experimental gray cast iron, it can be seen that the more the amount of modifier is added, the finer and curved the graphite structure of the experimental gray cast iron, and the smaller the lamellar spacing of the matrix pearlite. These two effects can not only improve the tensile strength of the gray cast iron, but also improve the microhardness of the gray cast iron matrix. It can be seen that the effect of modifier addition on the mechanical properties of experimental gray cast iron is corresponding to its effect on the microstructure of gray cast iron.