In the solidification process, because of the wide range of crystallization temperature, the basic metal skeleton is formed first when the alloy grows from liquid to solid. At this time, the liquid and solid phases coexist. When the alloy continues to grow to solid, the liquid metal needs to flow between the dendrites of the skeleton for feeding. With the increase of solid fraction, the flow channel between dendrites solidifies gradually, forming a closed isolated region. After the liquid metal in the region is completely solidified, shrinkage porosity will be formed in the casting. If the pouring temperature is too high, the liquid shrinkage of the casting will increase and the volume of shrinkage cavity (shrinkage porosity) will increase. Volume shrinkage of molten metal cooled from pouring temperature (TP) to liquidus temperature (TL) ε Liquid V can be expressed as:

Where, α Liquid V is the liquid shrinkage coefficient of the alloy.

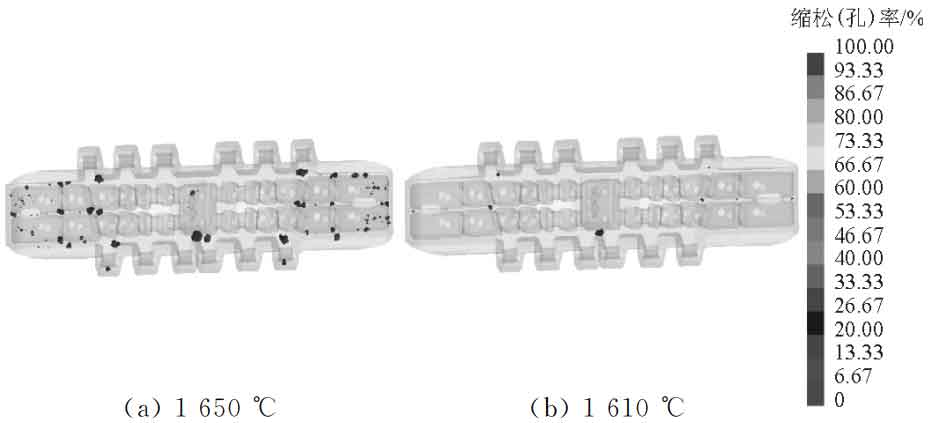

ProCAST software was used to calculate the effect of different pouring temperature on casting defects. The initial temperature of sand mold was 25 ℃ (room temperature) and pouring speed was 14 kg / s. The distribution of casting defects was calculated when pouring temperature was 1610 ℃ and 1650 ℃, The cut off method or niyama criterion can be used to confirm the location of the closed liquid isolated region, so as to determine whether the shrinkage porosity and shrinkage cavity will occur in these sensitive areas. The figure is the comparison of the final calculation results.

It can be seen that when the pouring temperature is 1650 ℃, a large area of defects appear at both ends of the track shoe, and the porosity of the shrinkage area in the middle part is 17.68%, which has a great impact on the mechanical properties of the casting, will shorten the service life of the casting, and there are some safety hazards in use.

When the pouring temperature is 1610 ℃, the defects at both ends of the track shoe are obviously reduced, only a small area of defects exist, and the porosity in the shrinkage area of the middle part is reduced to 5.42%, which has little effect on the mechanical properties and service life of the casting.

When the pouring temperature is increased from 1610 ℃ to 1650 ℃, the volume shrinkage can be calculated as 1.5% ~ 1.75% according to formula (2); Through ProCAST simulation calculation, the total volume of shrinkage cavity (shrinkage porosity) is increased from 0.42ml to 3.33ml, and the porosity is increased from 5.42% to 17.68%. It can be seen that different pouring temperature has a certain influence on the defects of the casting. When the pouring temperature is 1610 ℃, the porosity of the casting is increased from 5.42% to 17.68%, The shrinkage cavity (shrinkage porosity) formed in the inner part of the track shoe is obviously reduced.